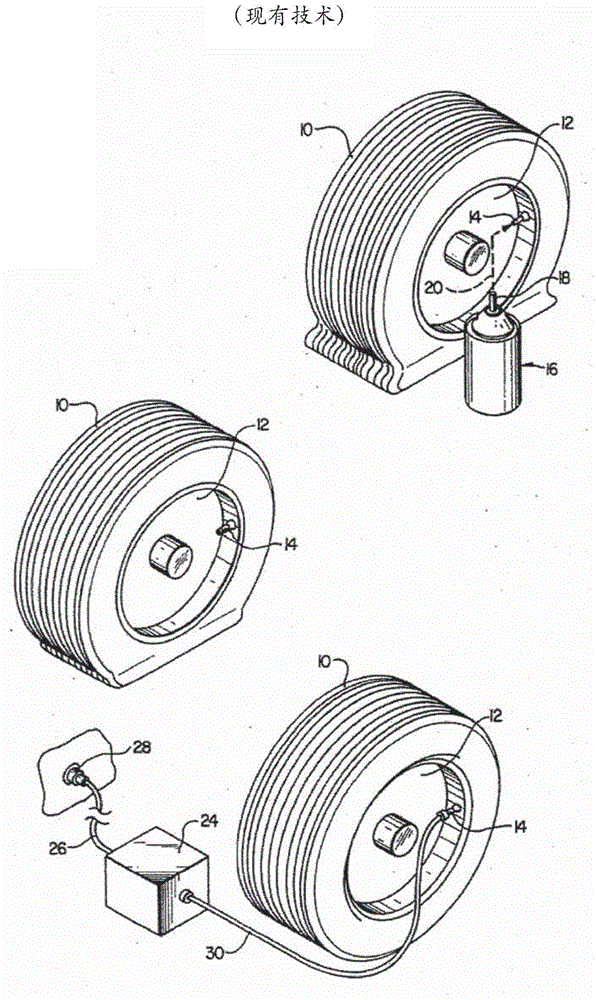

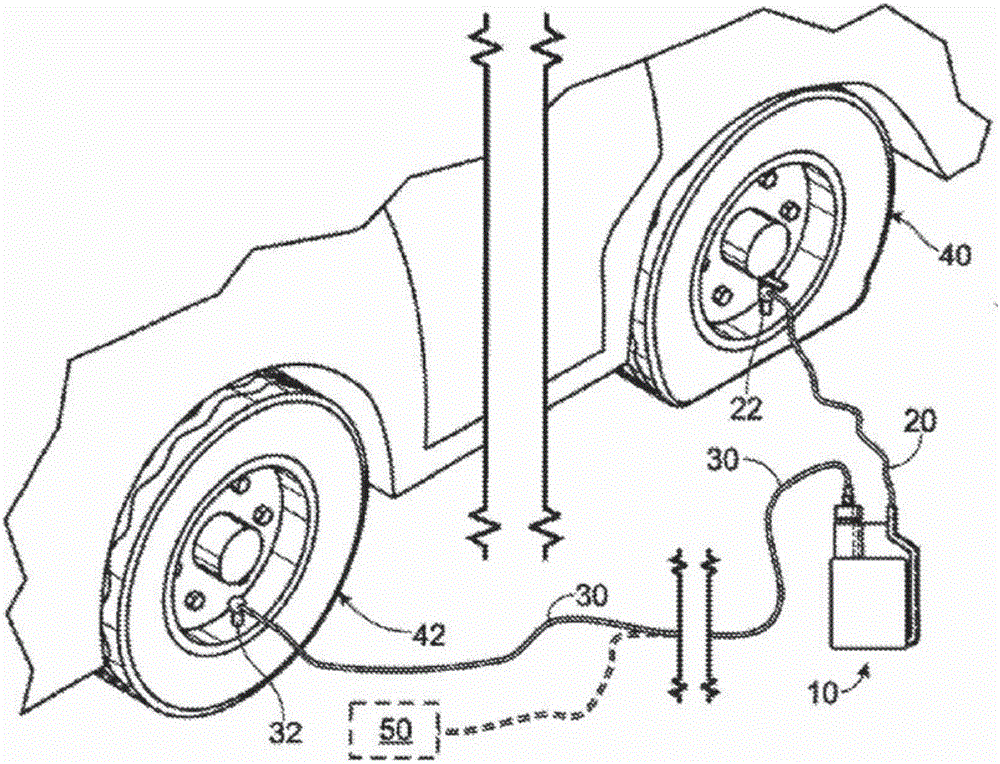

Tire inflation and sealing system

An air-tight, tire technology that is used in tire parts, tires, transportation and packaging to solve problems such as jeopardizing the ability of the donor tire to be driven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

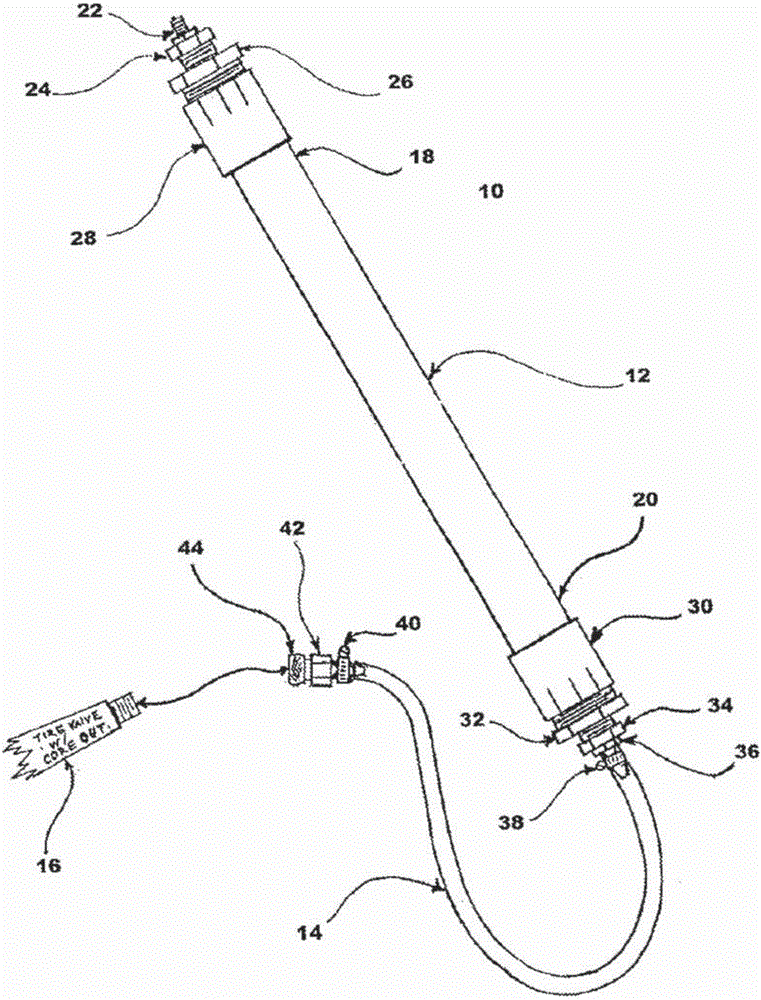

[0097] "Flow tube" hereafter refers to a flexible tube structure used as a gas cylinder and used as a channel to maintain a nearly equal cross-sectional flow surface, wherein the inner diameter of at least one end of the tube is Approximately equal to the inner diameter of a pneumatic inflation valve.

[0098] "Slime sealants" in this document refer to those liquid sealants that generally remain inactive until the sealant interacts under pressure with a puncture in a pneumatic tire. These sealants generally provide a durable and long-lasting solution for preventing punctures. These sealants are commonly known publicly under the collective term "slime", which comes from the trademark company and product name "Slime TM". These sealants are to be inserted in small quantities into the pneumatic tire and inner tube before they are deflated. In this case, these sealants are used only as a preventive measure. This is due to the difficulty of inserting these sealants through the valv...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap