Low-cost ferrite stainless steel with condensate liquid corrosion resistance and manufacturing method thereof

A manufacturing method and ferritic technology, applied in the field of ferritic stainless steel, can solve the problems of cost pressure, low guaranteed life, no longer meeting service life requirements, etc., to improve formability, formability, and condensate resistance. The effect of corrosion and oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] The present invention will be further described below in conjunction with embodiment.

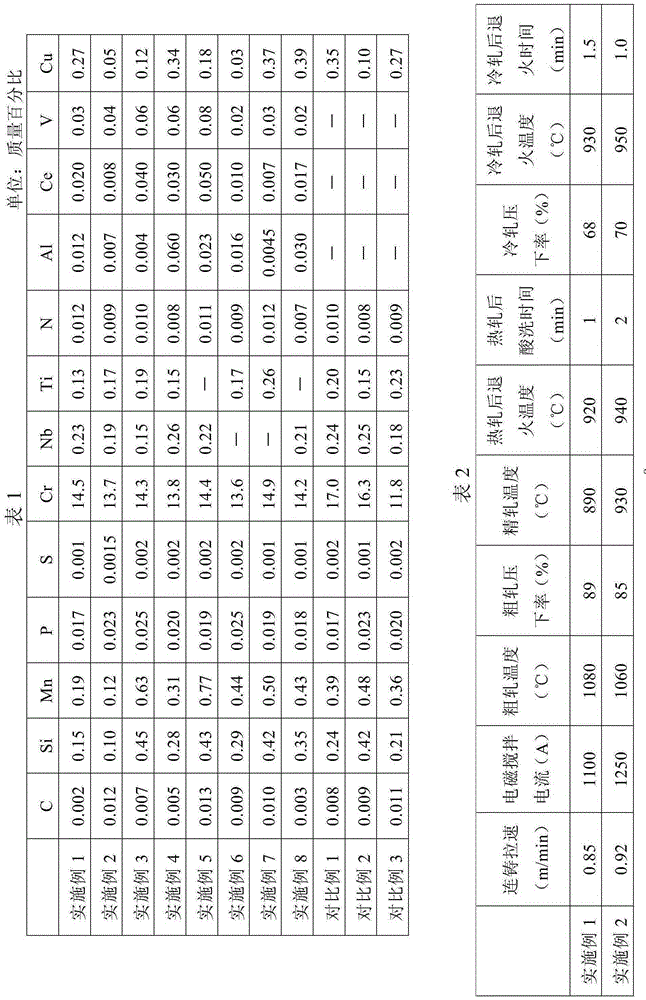

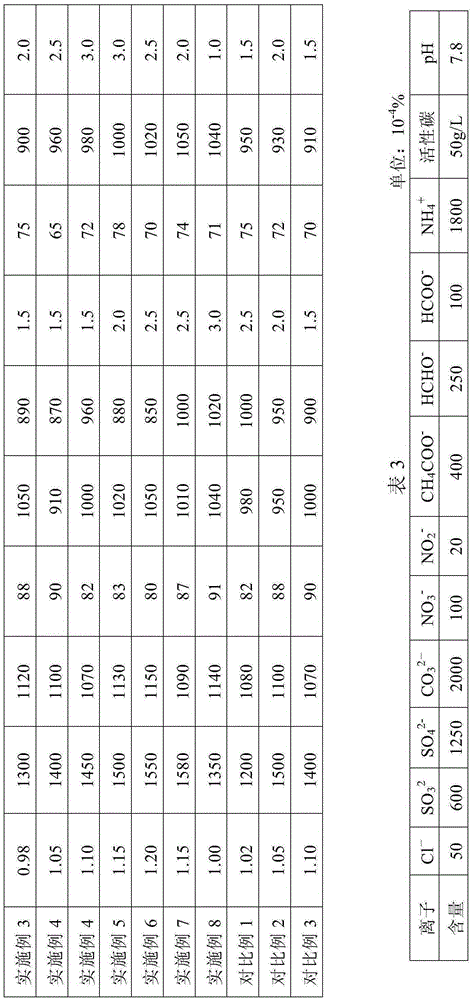

[0062] Table 1 shows the composition of the steels of the examples of the present invention and the comparative examples, wherein the steels of the comparative examples 1-3 are ferritic stainless steel exhaust system steels commonly used in automobiles at present. Table 2 is the manufacturing process of the steel of the embodiment of the present invention and the comparative example.

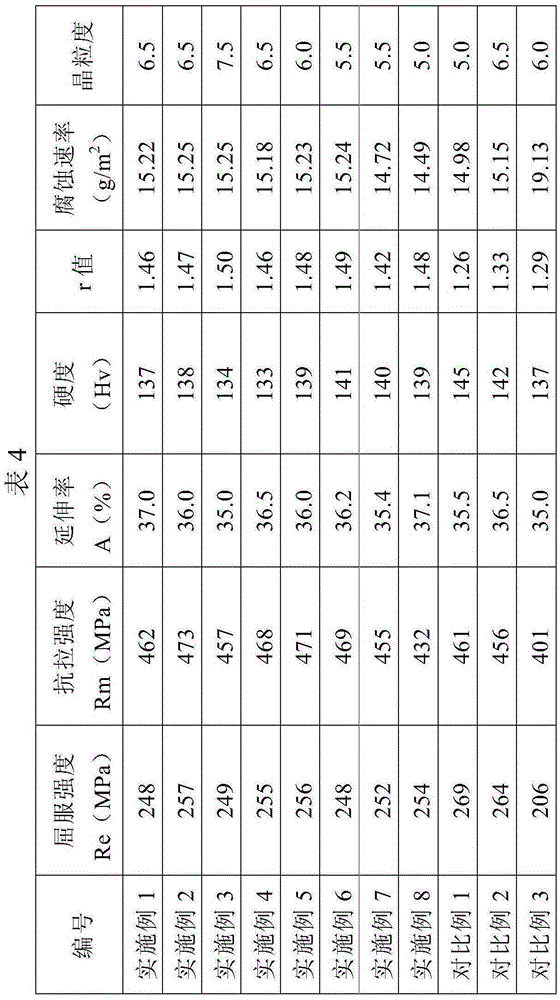

[0063] The corrosion performance of the embodiment of the present invention measures the condensate corrosion resistance, and the composition of the acid condensate corrosive liquid is shown in Table 3, and the SO is adjusted. 4 2- concentration. The test method is as follows: the steel sample is heated to 400°C and kept for 5 hours for later use. Soak the steel sample in the condensate at a constant temperature of 80°C for 24 hours. After the condensate is completely evaporated, clean the sample an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com