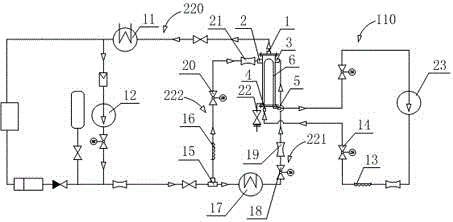

Testing loop of steam generator with axial preheater

A steam generator and test circuit technology, applied in the field of enhanced heat transfer, can solve the problems of poor preheating effect of the medium in the pressure shell, etc., achieve the effect of convenient control, simple structure, and improved heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

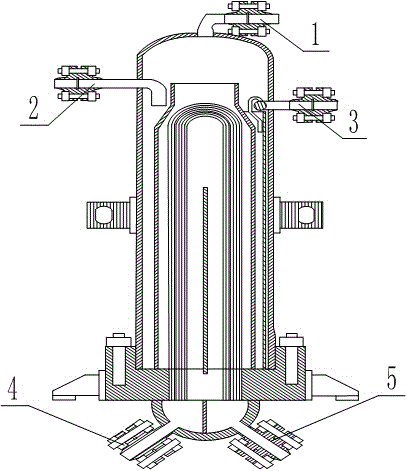

[0050] like figure 1 , figure 2 As shown, a test circuit with an axial preheater steam generator includes a heat source fluid circuit 110 and a recirculation water circuit 220. The heat source fluid circuit 110 provides a heat source for recirculation water and feed water, and the recirculation water The loop 220 includes a heat exchanger 11 and a circulating pump 12. The heat exchanger 11 cools the wet steam at the wet steam outlet 1 into saturated water of a given temperature and then divides it into a cold loop 221 and a hot loop 222 through a shielded pump. The cold loop 221 Used to return saturated water with a lower temperature to the cold end of the U-shaped pipe 6, and the hot circuit is used to return saturated water with a higher temperature to the hot end of the U-shaped pipe 6; the heat source fluid circuit includes a The primary side inlet 4 and the primary side outlet 5 connected at both ends of the tube 6 form a circulation pipeline between the primary side in...

Embodiment 2

[0052] like figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, the hot circuit 222 is provided with the second heater 16; the cold circuit 221 is provided with the condenser 17; the cold circuit 221 is provided with the second regulating valve 18 , the first flow meter 19; the third regulating valve 20 and the second flow meter 21 are arranged on the hot circuit; a pressure relief valve 22 is arranged at the lower end of the inlet 2 of the hot end of the secondary side on the steam generator with an axial preheater .

Embodiment 3

[0054] like figure 1 , figure 2 As shown, this embodiment is based on Embodiment 1, the cold circuit 221 is connected to the inlet 3 of the secondary side cold end by using a grooved falcon flange, and the hot circuit 222 is connected to the inlet 2 of the secondary side hot end by using a grooved falcon flange ; The recirculation water circuit 220 is connected to the wet steam outlet 1 using a grooved falcon flange; the heat source fluid circuit 110 is connected to the primary side inlet 4 and the primary side outlet 5 using a grooved falcon flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com