Duplexer with Circulating Heating

A technology of circulating heating and double-sided machine, applied in layered products, lamination devices, lamination and other directions, can solve problems such as low heating efficiency, and achieve the effect of increasing heating efficiency and avoiding energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

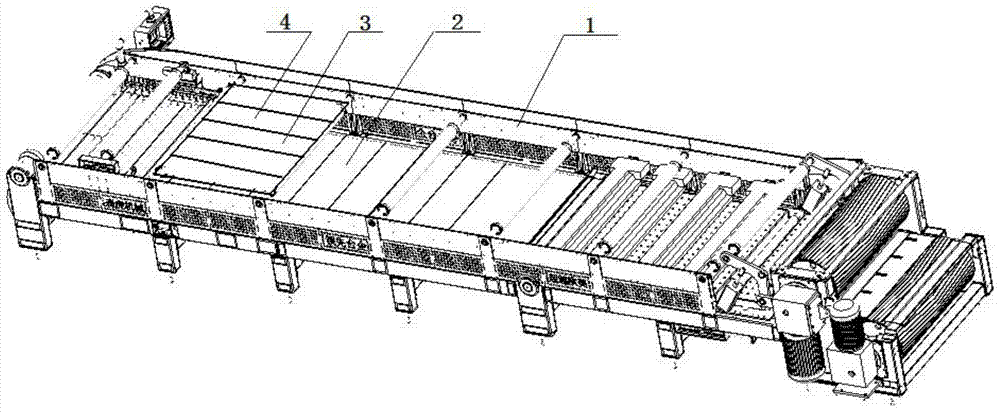

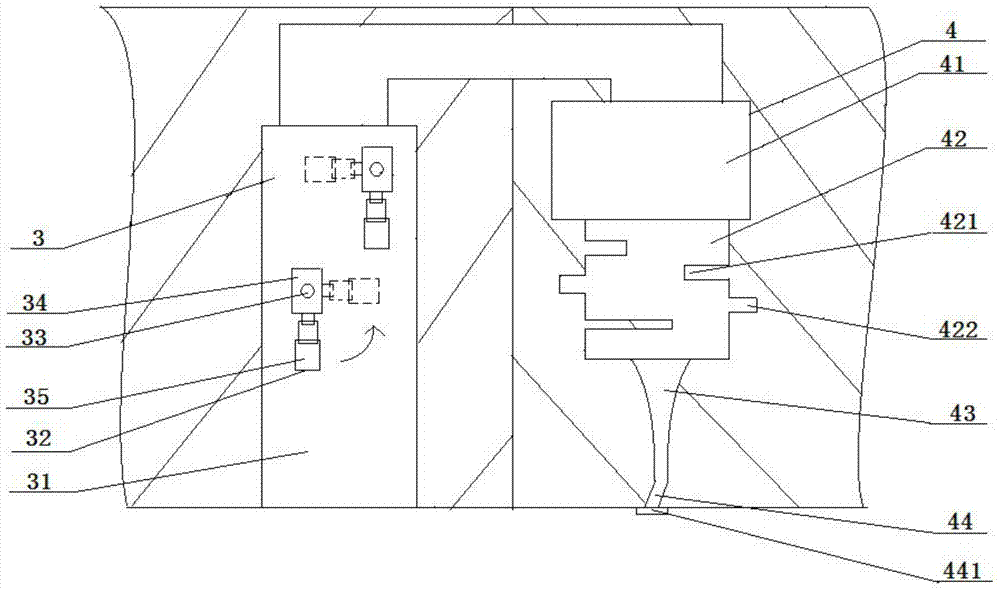

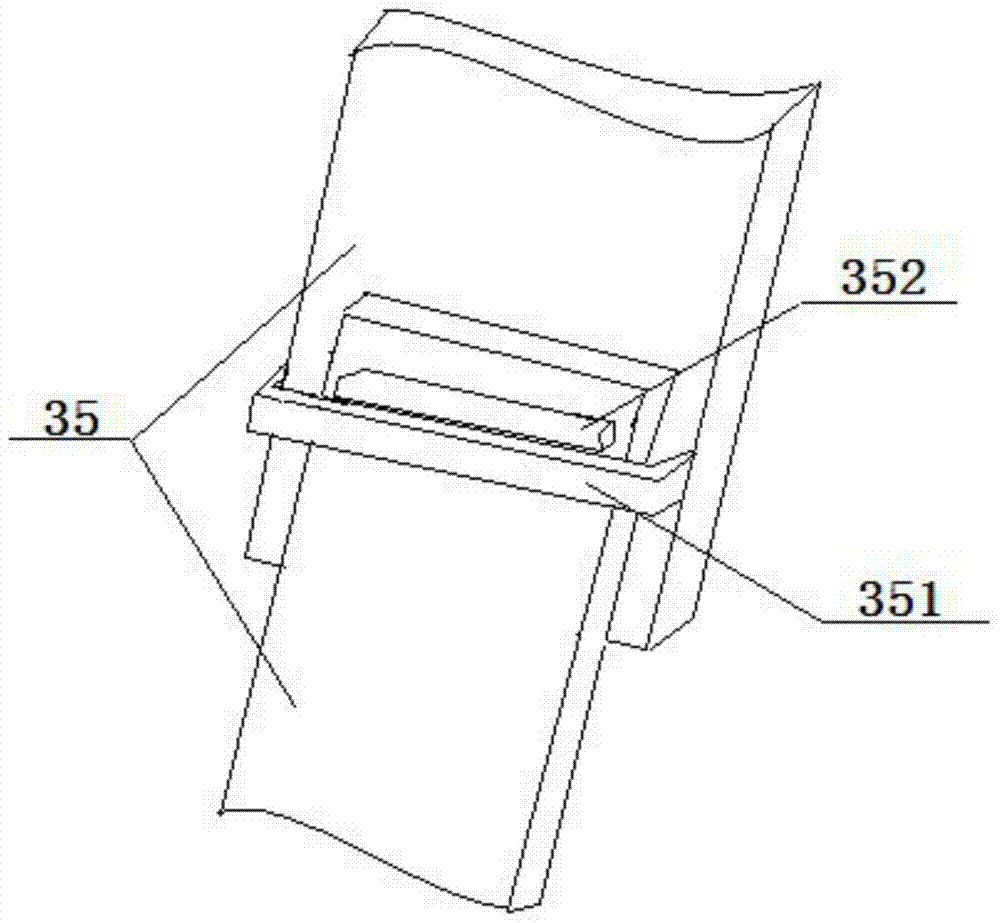

[0017] The double-sided machine with circulation heating function, as shown in the figure, includes a frame 1 and a hot plate 2 installed in the frame 1. The hot plate 2 is laid flat inside the frame 1 and heats the glued corrugated paper , also includes a recovery chamber 3 and an accelerated exhaust chamber 4 connected to the recovery chamber 3, the recovery chamber 3 and the accelerated exhaust chamber 4 are installed above the hot plate 2 and arranged longitudinally along the direction of movement of the corrugated paper in the frame 1, the machine The frame is provided with three recovery chambers 3 and two accelerated exhaust chambers 4, and the lower surface of the recovery chamber 3 is provided with an air intake hole 31, and a guide telescopic wheel 32 is installed in the air intake hole 31, and the guide telescopic wheel 32 is driven by a motor Rotate and guide the steam into the recovery chamber 3, and accelerate the exhaust chamber 4 to accelerate the steam in the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com