A waterproof shoe and its manufacturing method

A production method and technology of waterproof shoes, applied in the field of shoes, can solve the problems of large luck components, wrinkling, difficult to block pores, etc., and achieve the effect of stable waterproofness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in further detail below in conjunction with the accompanying drawings.

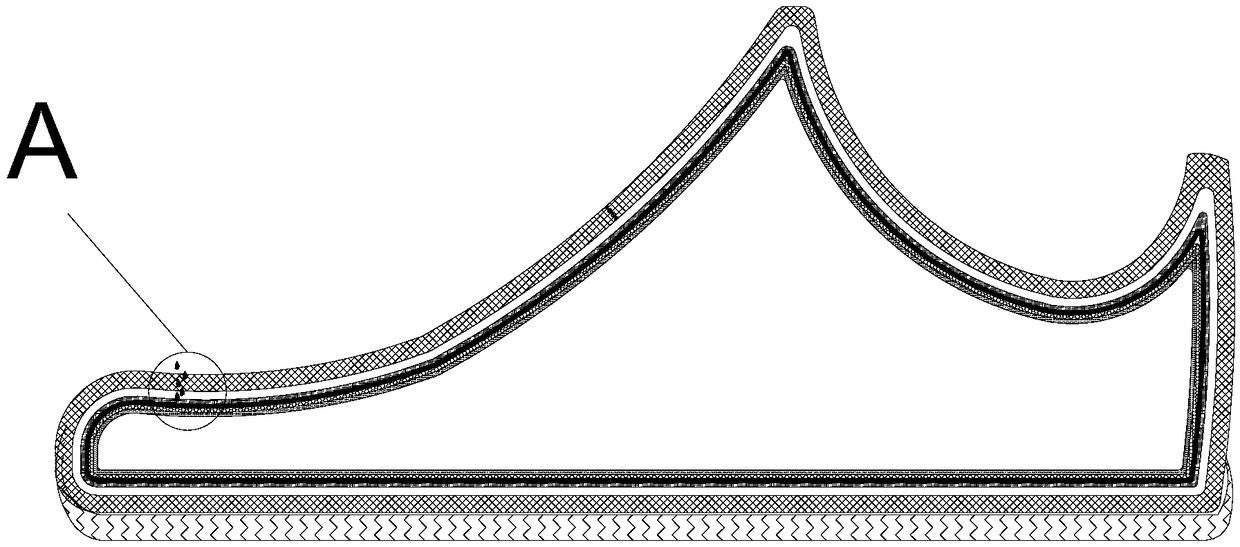

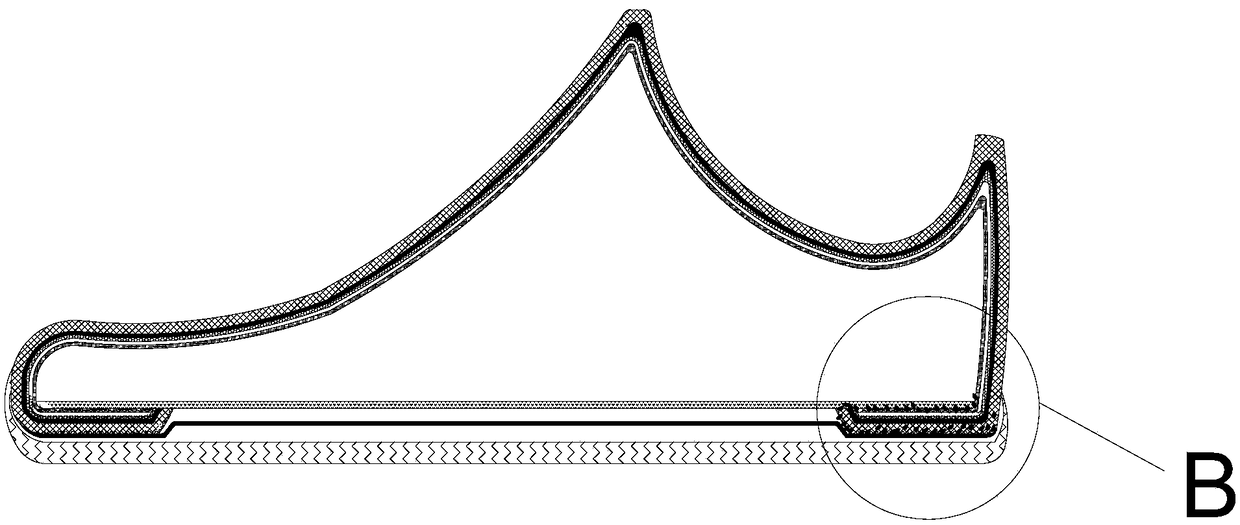

[0039] Figure 5 to Figure 9 A waterproof shoe according to an embodiment of the present invention is schematically shown. As shown in the figure, the device includes a shoe sole 1 and a shoe body 2 fixed on the upper part of the shoe sole 1 .

[0040] Wherein, the shoe body 2 is mainly composed of a waterproof shoe cover 3 and an inner layer 4 .

[0041] The waterproof shoe cover 3 is composed of two or more waterproof material sheets 3a.

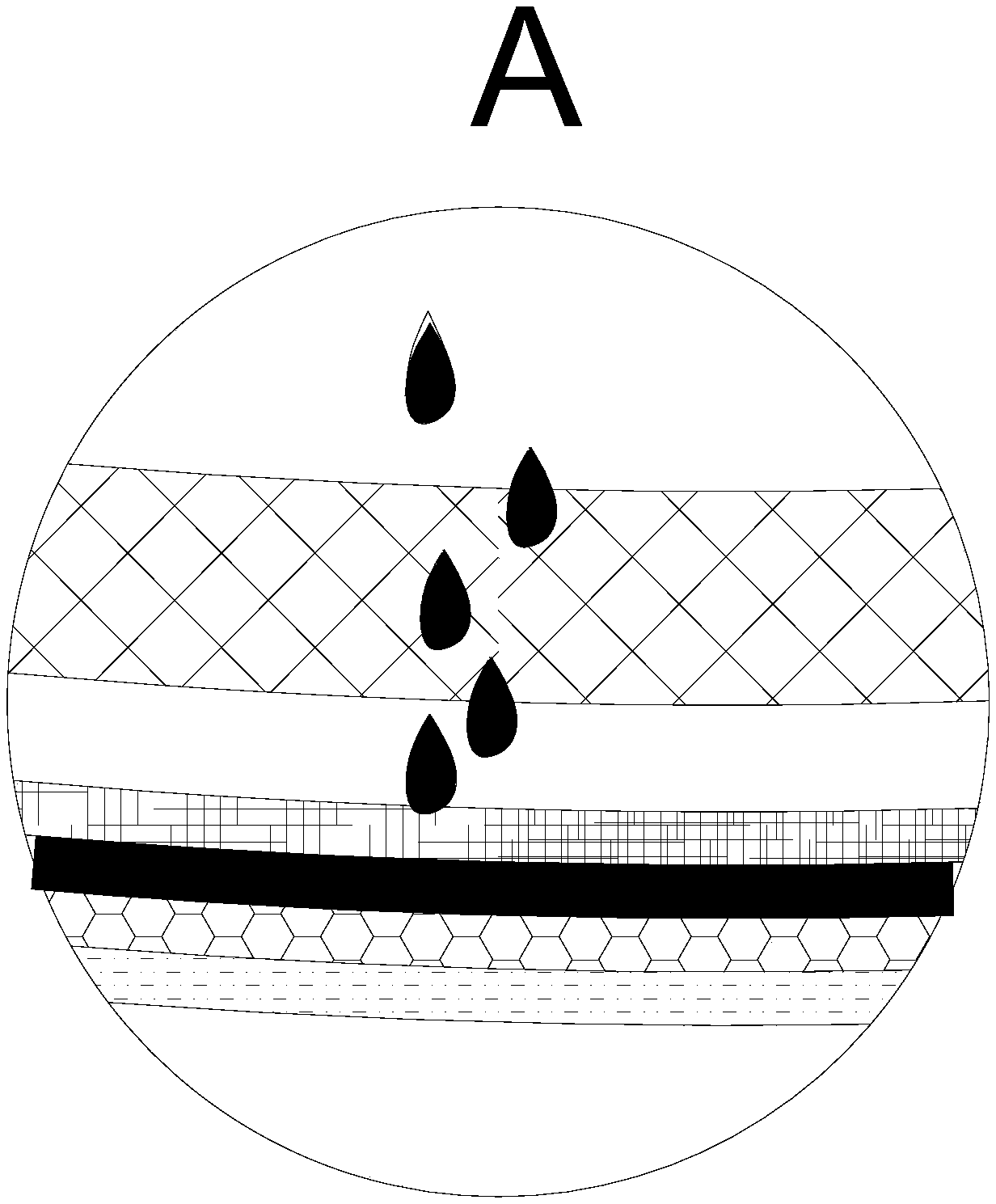

[0042] The waterproof material sheet 3 a is composed of a waterproof membrane 32 , a surface layer 31 and a nylon mesh layer 33 respectively attached to both sides of the waterproof membrane 32 .

[0043] Two or more sheets of waterproof material 3a are spliced into a three-dimensional shoe cover with the surface facing outwards by stitching.

[0044] A professional waterproof adhesive tape 5 is pasted on the joint ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com