An automatic cleaning filter and power generation system

An automatic cleaning and filter technology, applied in the direction of moving filter element filters, filtration separation, engine components, etc., can solve the problems of tediousness, complicated cleaning process of filter meshes, increased use cost, etc., to reduce use cost and achieve good cleaning. function, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

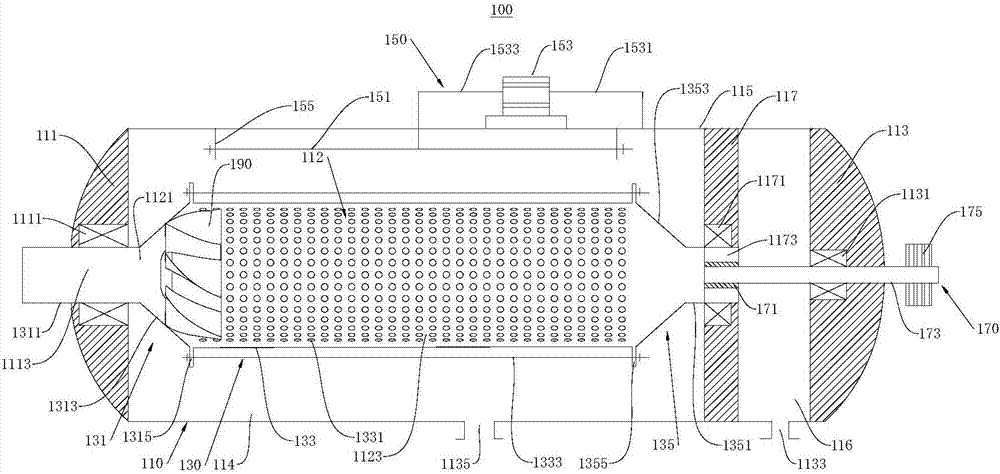

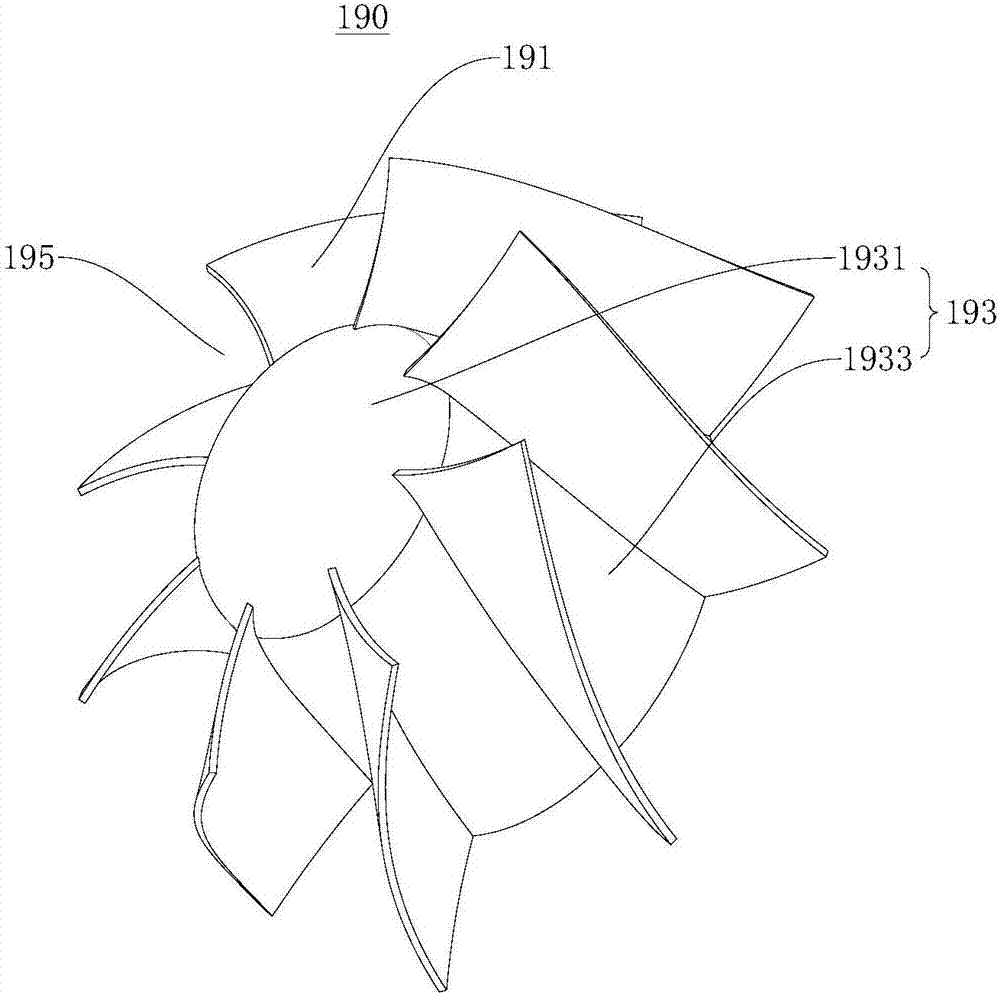

[0029] figure 1 It is a schematic structural diagram of the self-cleaning filter 100 provided in the first embodiment of the present invention. The self-cleaning filter 100 provided by the present invention is mainly used in water filtration systems, such as tap water filtration, industrial water filtration, and dirty water filtration in agricultural irrigation. In this embodiment, the dirty water filtration in agricultural irrigation is taken as an example for illustration. After the dirty water is filtered through the self-cleaning filter 100, it becomes clean water that can be used for farmland irrigation; at the same time, the kinetic energy generated in the filtering process is converted into a into electricity, so as to achieve the role of hydroelectric power generation.

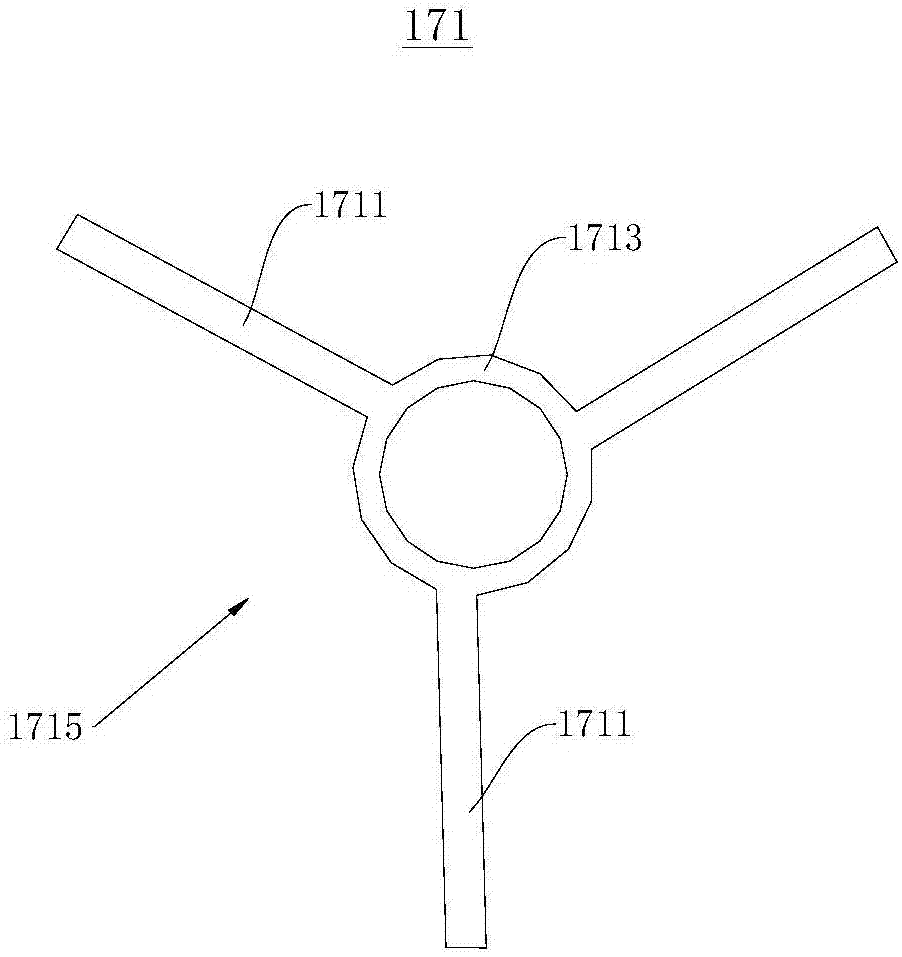

[0030] see figure 1, The self-cleaning filter 100 provided by the first embodiment of the present invention includes a housing 110 , a filter assembly 130 , a flushing assembly 150 , a transmission a...

no. 2 example

[0062] Figure 4 It is a schematic diagram of the power generation system 10 provided by the second embodiment of the present invention. The power generation system 10 is mainly used for energy conversion in the hydroelectric power generation process, for example, the kinetic energy generated in the dynamic filtration process is used for conversion through power generation equipment.

[0063] In this embodiment, the power generation system 10 includes a self-cleaning filter 200 and a power generation device 300. The basic structure and working principle of the self-cleaning filter 200 provided in this embodiment are the same as those of the first embodiment. For a brief description, this embodiment For the parts not mentioned in the example part, reference may be made to the corresponding content in the first embodiment. The self-cleaning filter 200 is connected to the power generation device 300, and the power generation device 300 is connected to the electrical appliance 40...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com