Spherical axe type ship bow suitable for medium-high speed ship

A medium-high-speed, ball-axe-type technology, applied to the hull, hull bow, ship parts, etc., can solve problems that do not conform to the concept of green ship development, increase navigation resistance, rollover, etc., and eliminate the wave rollover and splashing of the bow , reduce sailing resistance, and lengthen the waterline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

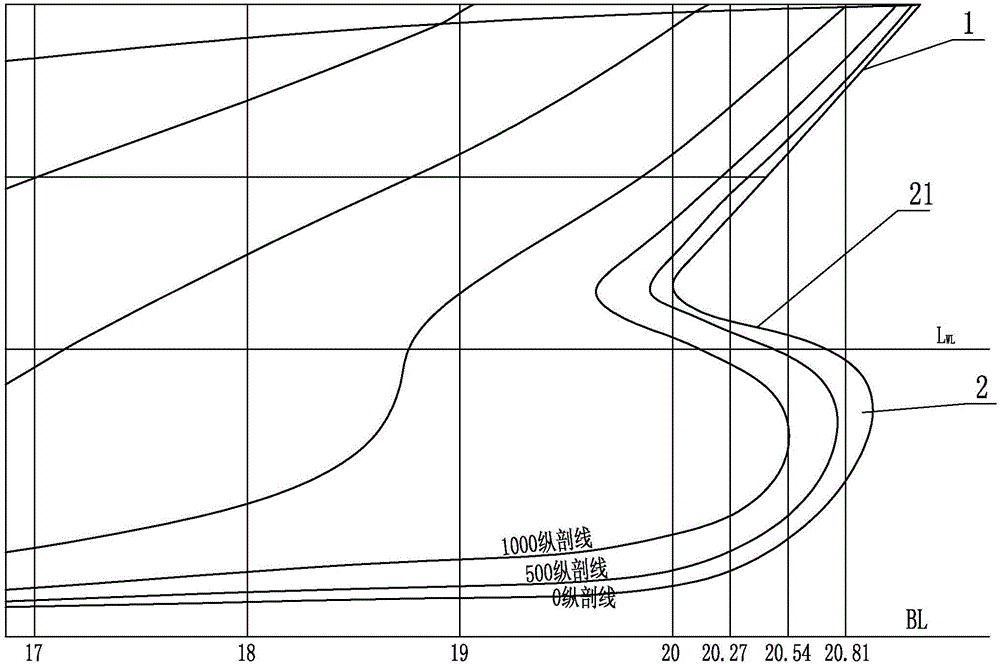

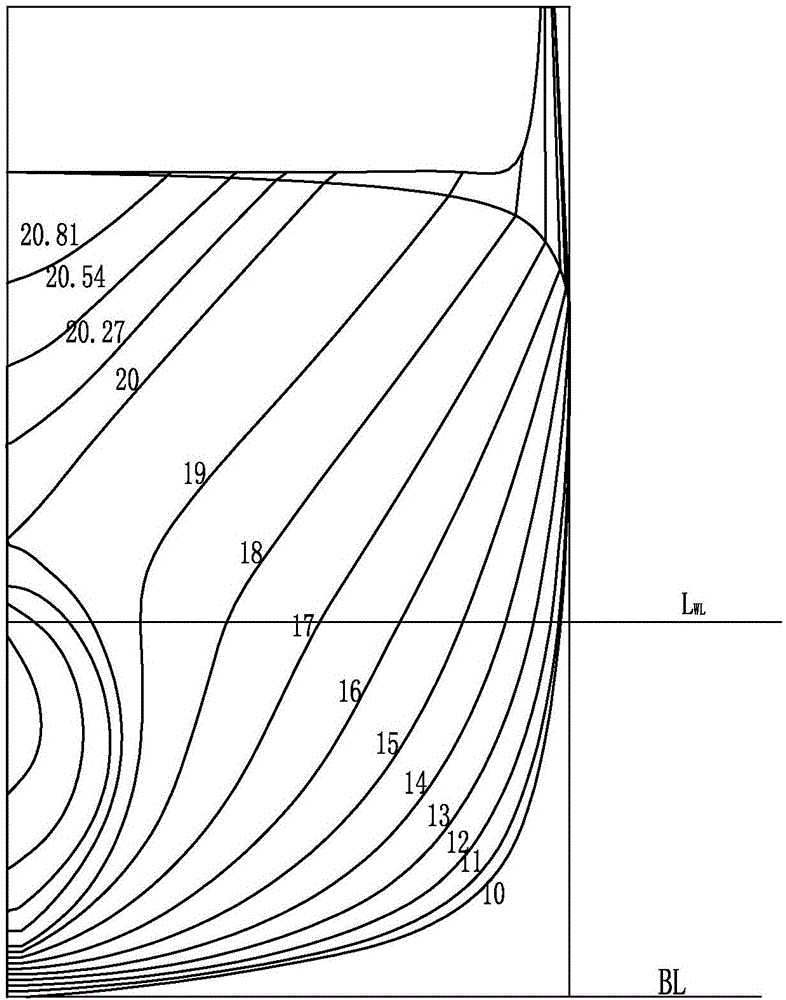

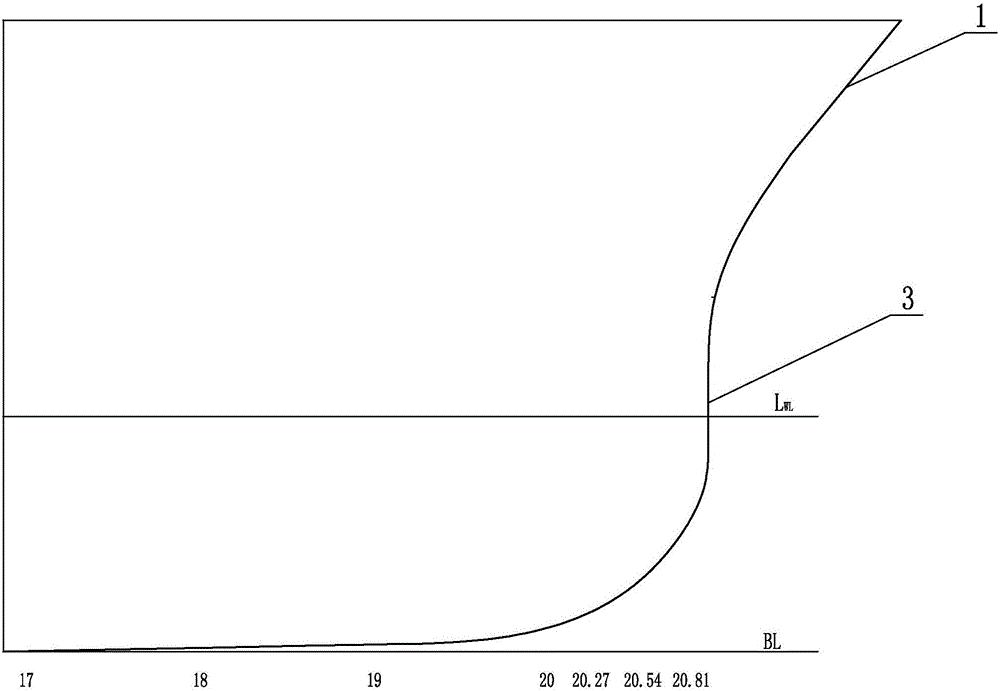

[0026] See image 3 , Figure 4 , the present invention includes a bow 1 inclined forward and a bulbous bow 2 protruding forward, and the bulbous bow 2 is located at the design waterline L WL below; in the half-width direction from the two ends of the medium-high-speed ship to the centerline plane of the medium-high-speed ship, the horizontal length of the bulbous bow 2 protruding forward gradually decreases, and on the centerline plane of the medium-high-speed ship Above, the lower surface of the bulbous bow 2 is connected with the vertical column section 3 above to form an ax-shaped bow, the vertical column section 3 intersects the design waterline, the middle and lower part of the vertical column section 3 is in line with the design The waterlines intersect, and on the longitudinal profile line corresponding to the midline plane of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com