Long-distance underground passage wiring mechanism and wiring method thereof

An underground passage, long-distance technology, used in the transportation of filamentous materials, cable laying equipment, thin material processing, etc., to achieve the effect of improving wiring efficiency, good stability, and improved safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

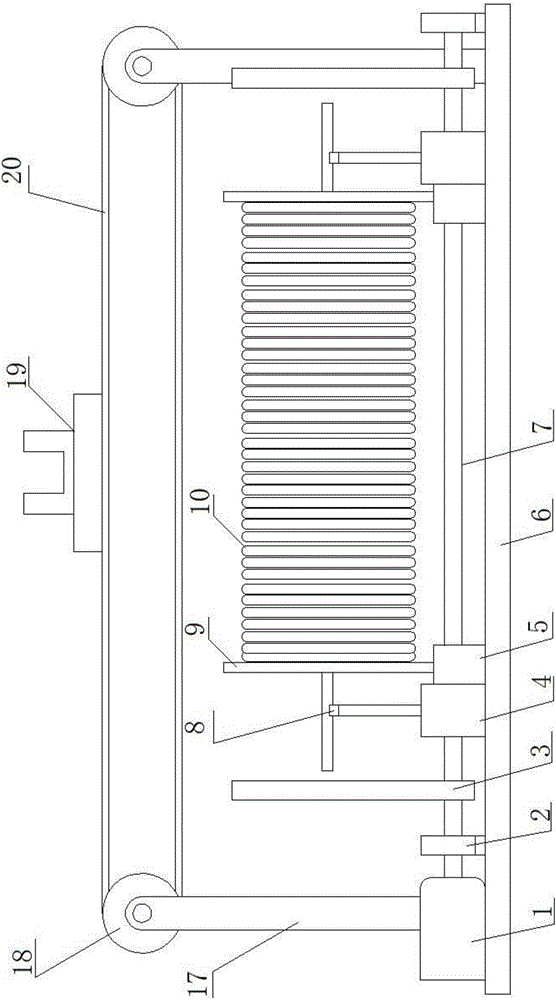

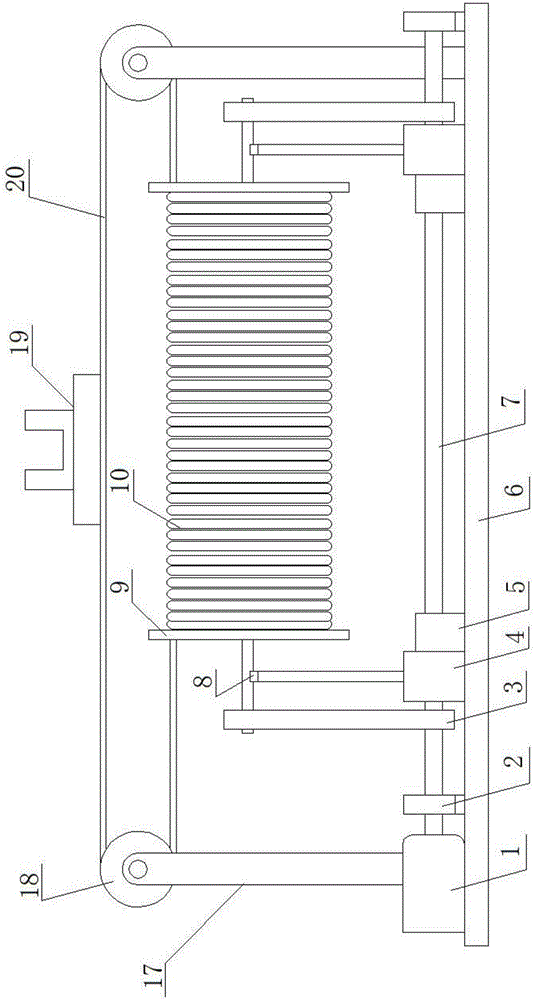

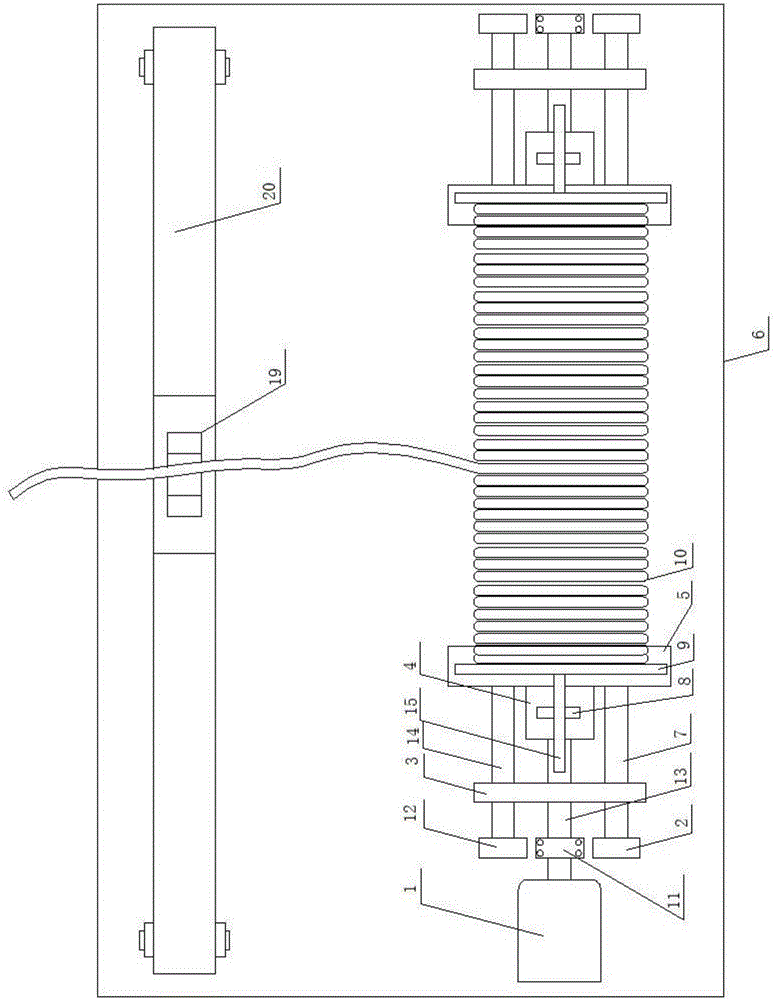

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0030] It should be noted that the present invention includes partially symmetrical structures, especially left-right symmetrical structures, such as figure 1 , figure 2 and image 3 . Here, only parts of these symmetrical structures are marked, and the unmarked parts can be understood with reference to the context and marked parts. For example, "If figure 1 , the two support plates 3" should be understood as including the left support plate 3 and the right support plate (not marked).

[0031] Such as Figure 8 , the cable reel is composed of two side disks 9 on the left and right sides, the center of the two side disks 9 is passed by a central axis 15, and there is a winding drum 16 between the two side disks 9, and the cable 10 is wound on the winding cylinder 16.

[0032] During construction, it is necessary to support and raise the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com