Overlong bolt pile and construction method thereof

A construction method and screw technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve the problems of inconvenient construction and height influence, and achieve the effect of convenient transportation and firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

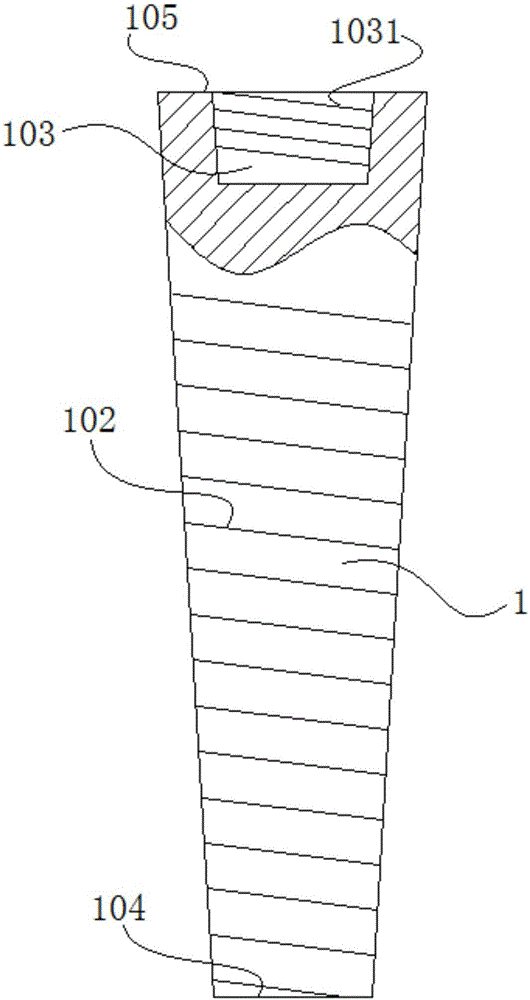

[0031] An ultra-long screw pile is characterized in that N-level screw piles are composed of N screw pile units 1. N is a natural number greater than 2. The first-level screw pile unit 1 is the lowest level of the super-long screw pile, and the N-th level screw pile unit 1 is the uppermost level of the super-long screw pile. The super-long screw piles are grade N, grade N-1, ..., grade 2, grade 1 from top to bottom. From top to bottom of the super-long screw pile, the smaller diameter end of each level of screw pile unit 1 is screwed into the blind hole 103 of the next level of screw pile unit 1, finally forming a complete super-long screw pile.

[0032] The screw pile unit 1 of each stage is an inverted circular platform, and the bottom surface of the screw pile unit 1 with a smaller diameter is the bottom surface I104 of the circular platform. The bottom surface of the screw pile unit 1 with a larger diameter is the bottom surface II 105 of the circular platform, and the b...

Embodiment 2

[0040] The main structure of this embodiment is the same as that of Embodiment 1, further: this embodiment provides some dimension parameters of the present invention.

[0041] The diameter of the bottom surface II 105 of the screw pile unit 1 is 500-1000 mm. The commonly used dimensions of the screw pile unit 1 are shown in Table 1.

[0042] Table 1 Common dimensions of screw piles

[0043]

Embodiment 3

[0045] A kind of construction method about the ultra-long screw pile described in embodiment 1, comprises the following steps:

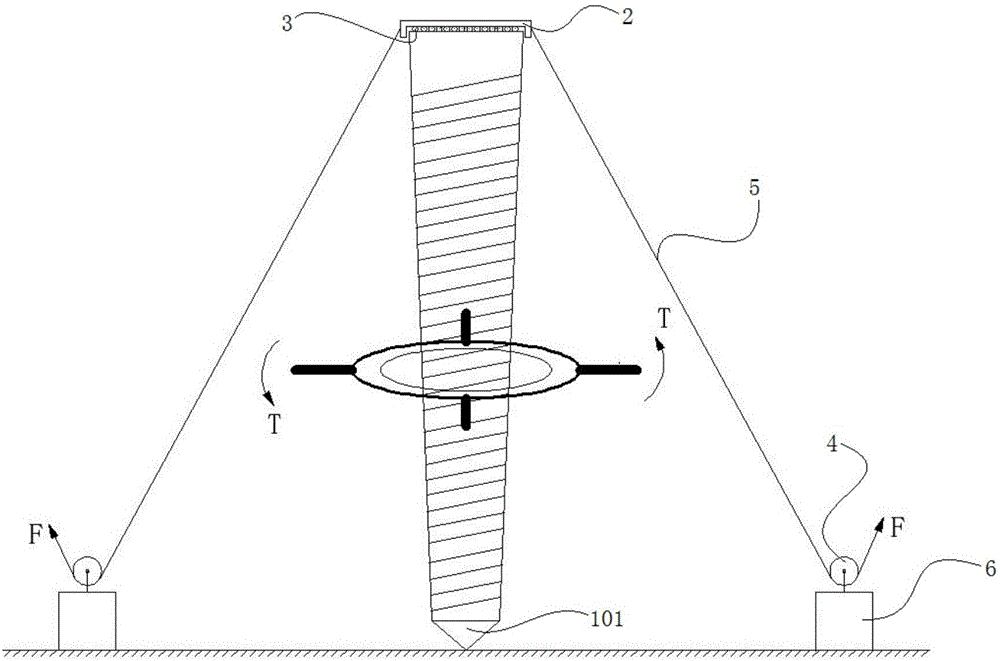

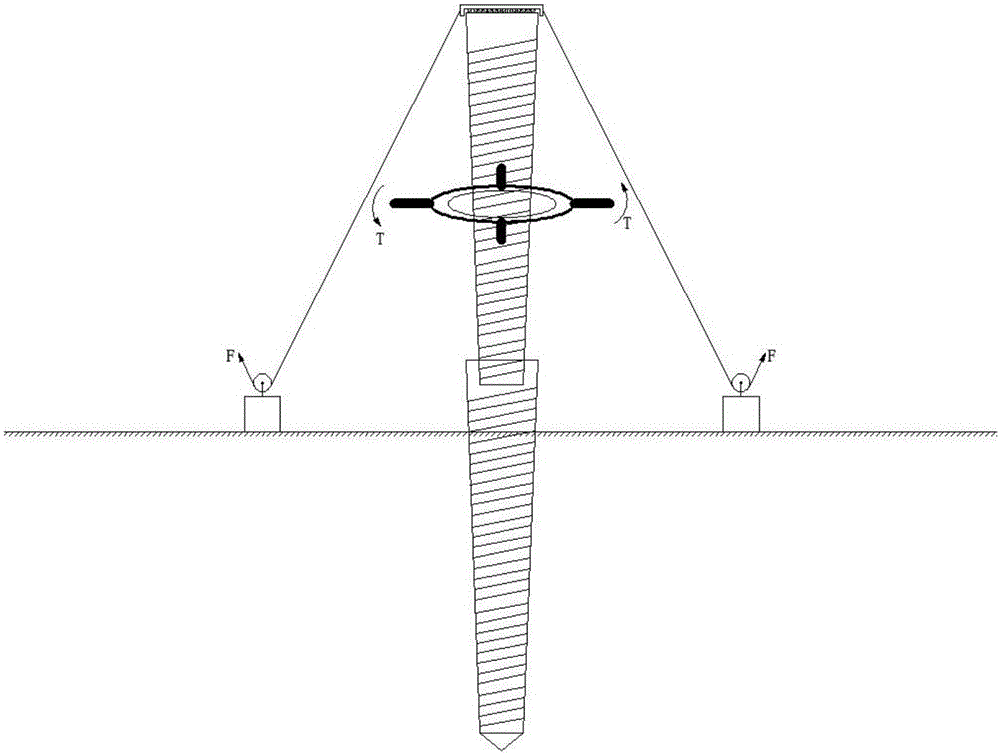

[0046] 1).Initial pile insertion, align the pile tip 101 of the first-level screw pile unit 1 vertically downward to the pile position, and use a pressure-applying device to press the pile tip 101 into the ground to a certain depth at the upper end of the first-level screw pile unit 1 .

[0047] 2). After the pile tip 101 is inserted into the ground, keep the upper end pressure, and at the same time apply torque to the screw pile unit 1 to rotate the screw pile unit 1, so that the screw pile unit 1 continues to screw into the ground.

[0048] After the screw pile unit 1 is stable, you can stop applying pressure, only apply torque, and twist the pile body until the part screwed into the foundation reaches more than 4 / 5 of the screw pile unit 1, then stop applying torque and pressure.

[0049] 3). Take another second-level screw pile unit 1, and screw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com