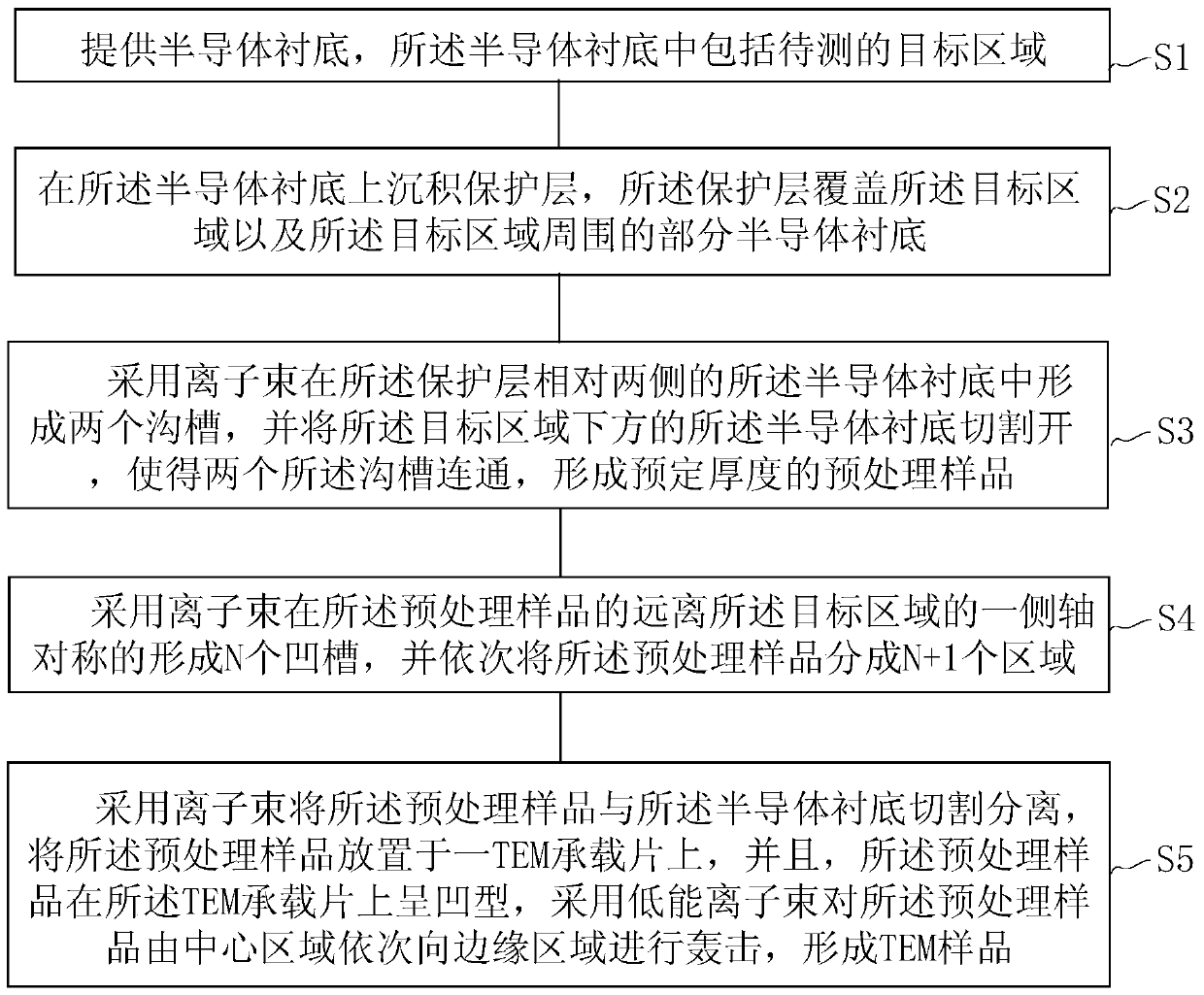

tem sample preparation method

A sample and semiconductor technology, which is applied in the field of TEM sample preparation, can solve the problems that it is difficult to obtain a clear high-resolution TEM image, the sample is easy to bend, and the image is blurred, etc., so as to achieve the effect of clear TEM image

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

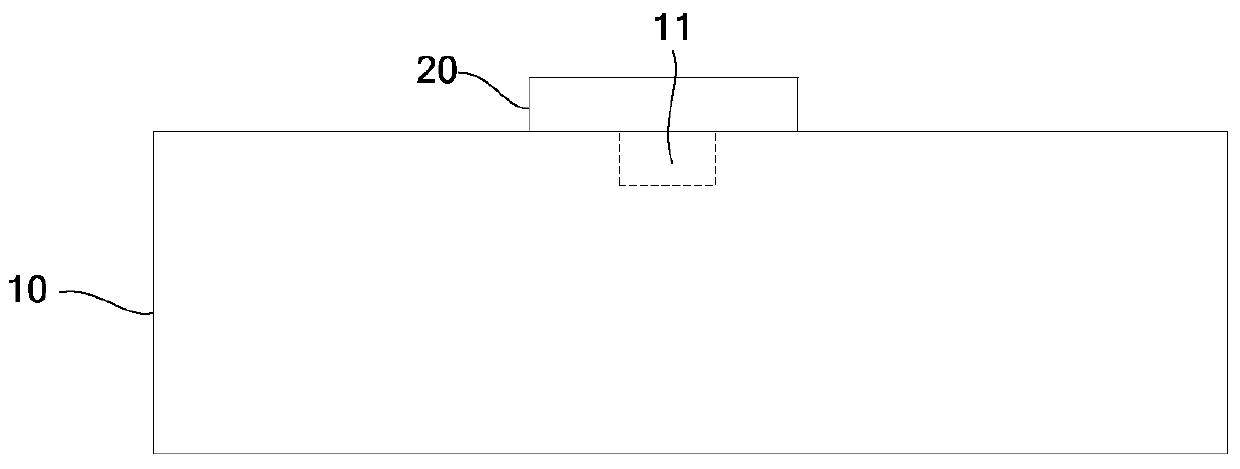

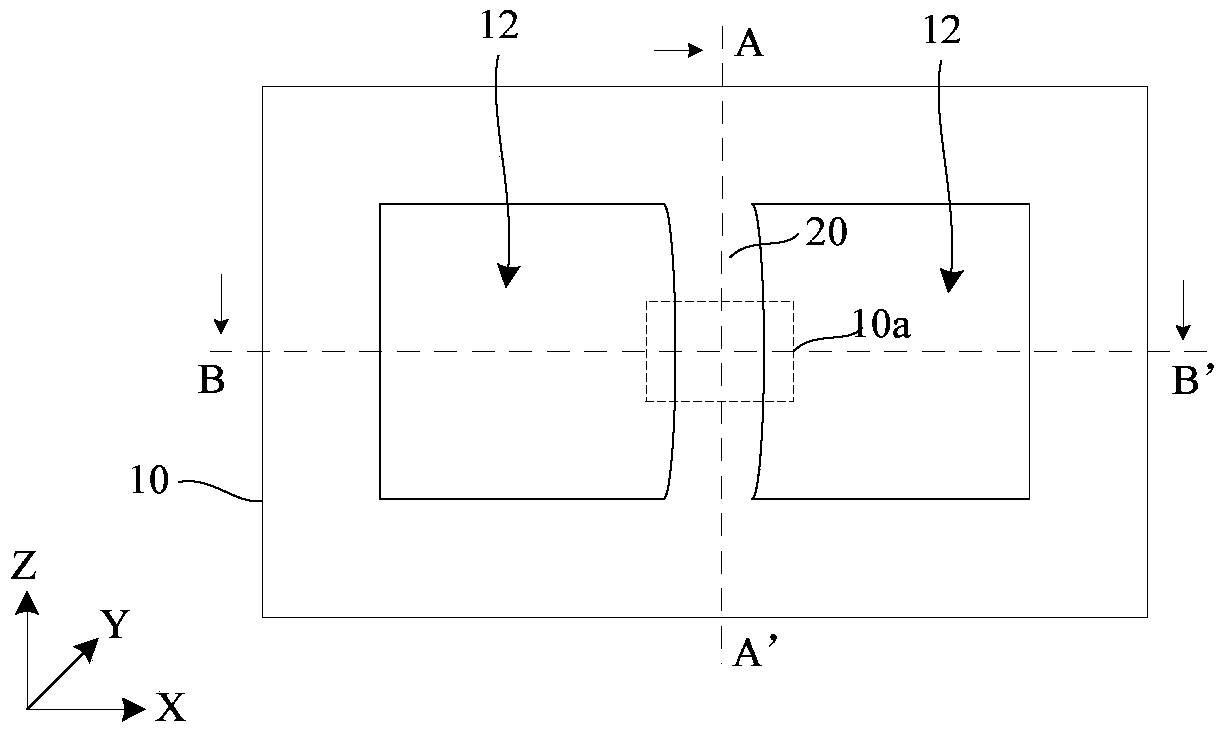

[0033] As mentioned in the background art, the pretreated sample after FIB cutting and thinning is prone to bending phenomenon, resulting in blurred test images. For this reason, the present invention provides a kind of preparation method of TEM sample, uses ion beam to form a plurality of grooves in the pretreatment sample, and the groove releases the stress of the pretreatment sample, after that, the pretreatment sample is placed on the TEM bearing in a concave shape. On the chip, a low-energy ion beam is used to bombard the pretreated sample symmetrically from the center area to the edge area in sequence. Due to the impact of the ion beam, the pretreated sample is sequentially attached to the TEM carrier sheet, and finally it is completely attached to the TEM carrier sheet. combine. In this way, when observed by TEM, the transmitted electrons can be perpendicular to the TEM sample, so that the imaging is clear, thereby improving the quality of TEM imaging.

[0034] figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com