Cutting device for range hood aluminum plate

A technology of cutting device and range hood, applied in workshop equipment, manufacturing tools, etc., can solve problems such as position deviation of aluminum plate cutting line, failure to install to quadrangular inspection port, quadrangular aluminum plate does not meet the design requirements, etc., to achieve the goal of increasing levelness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

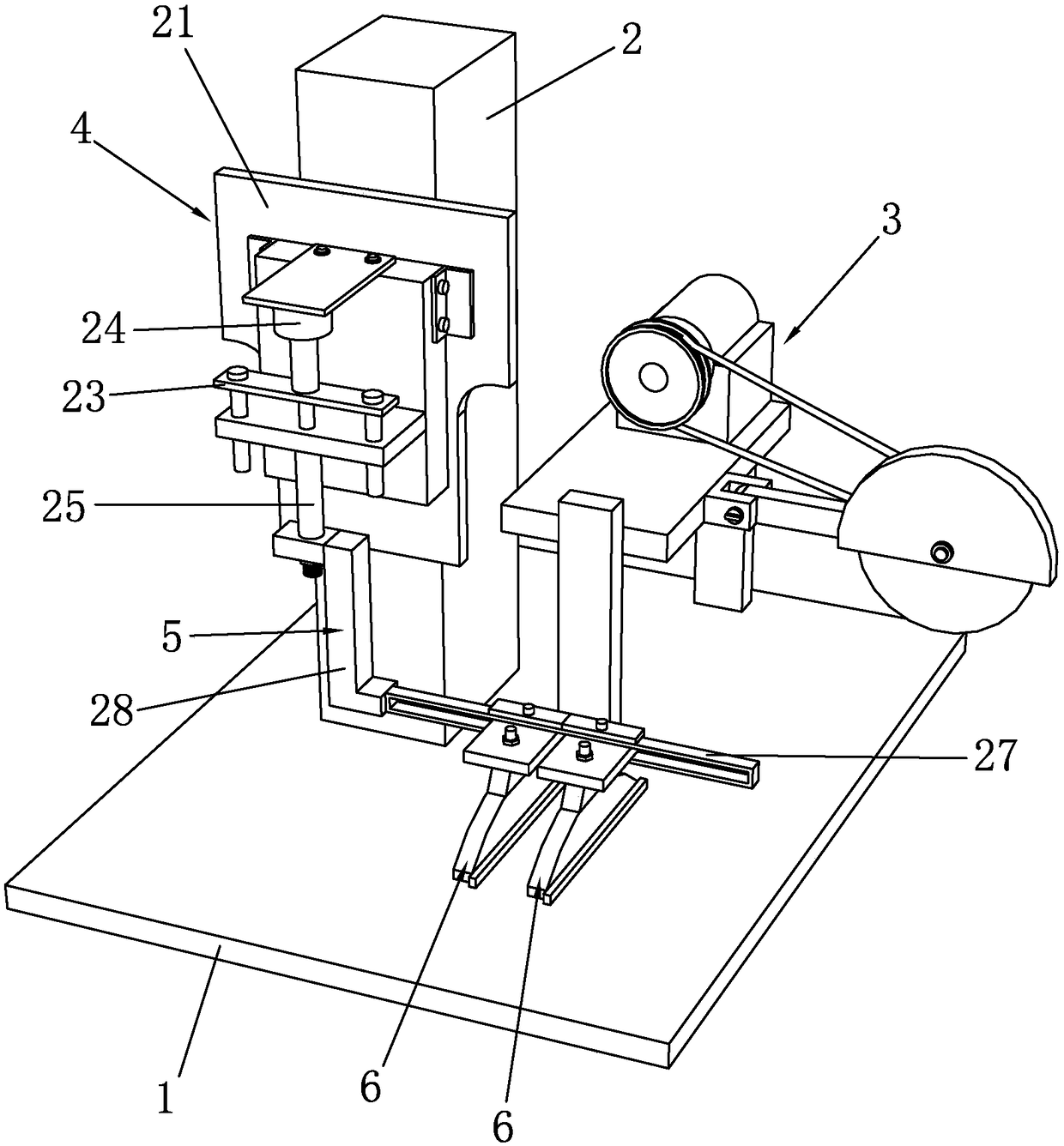

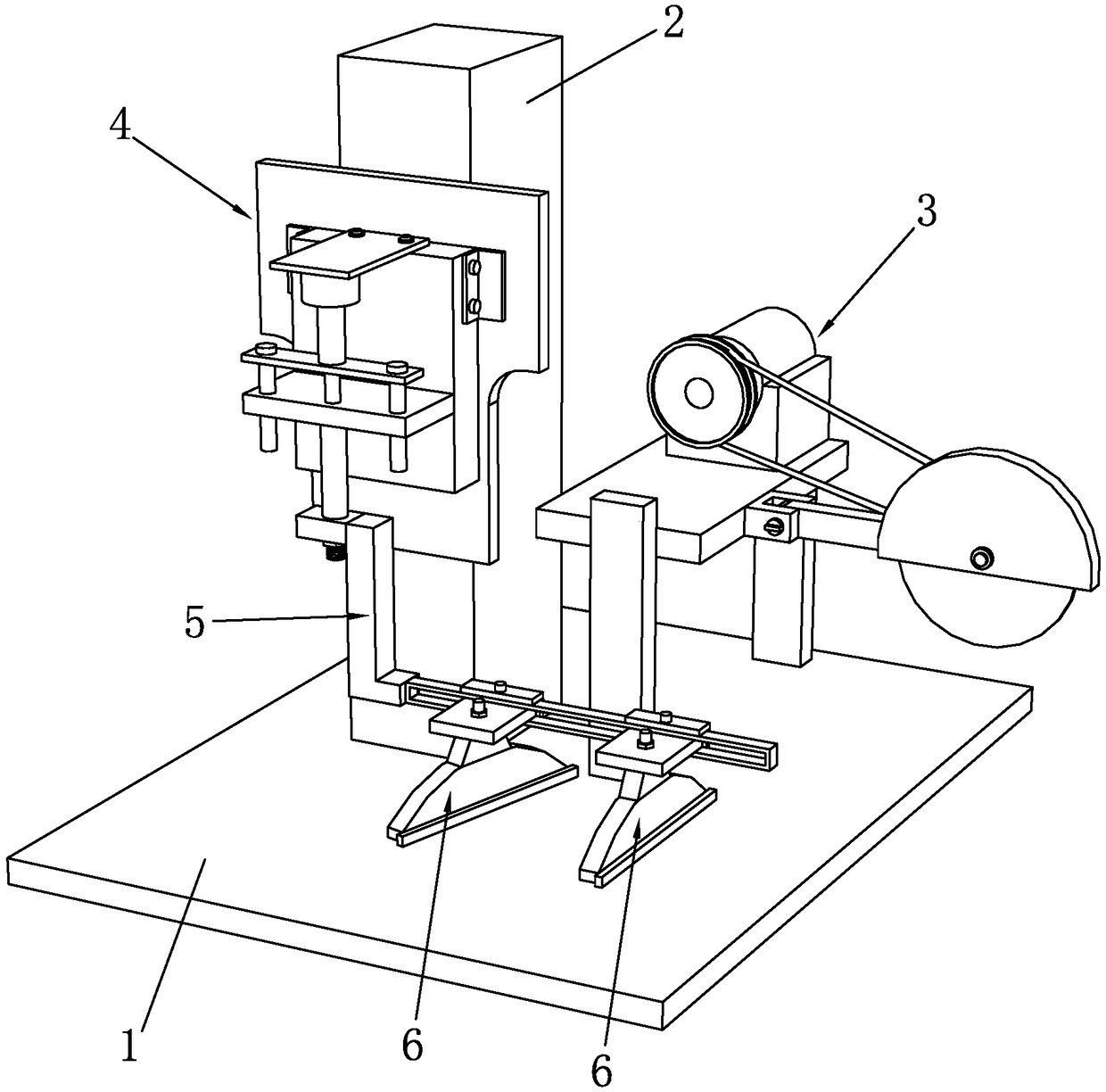

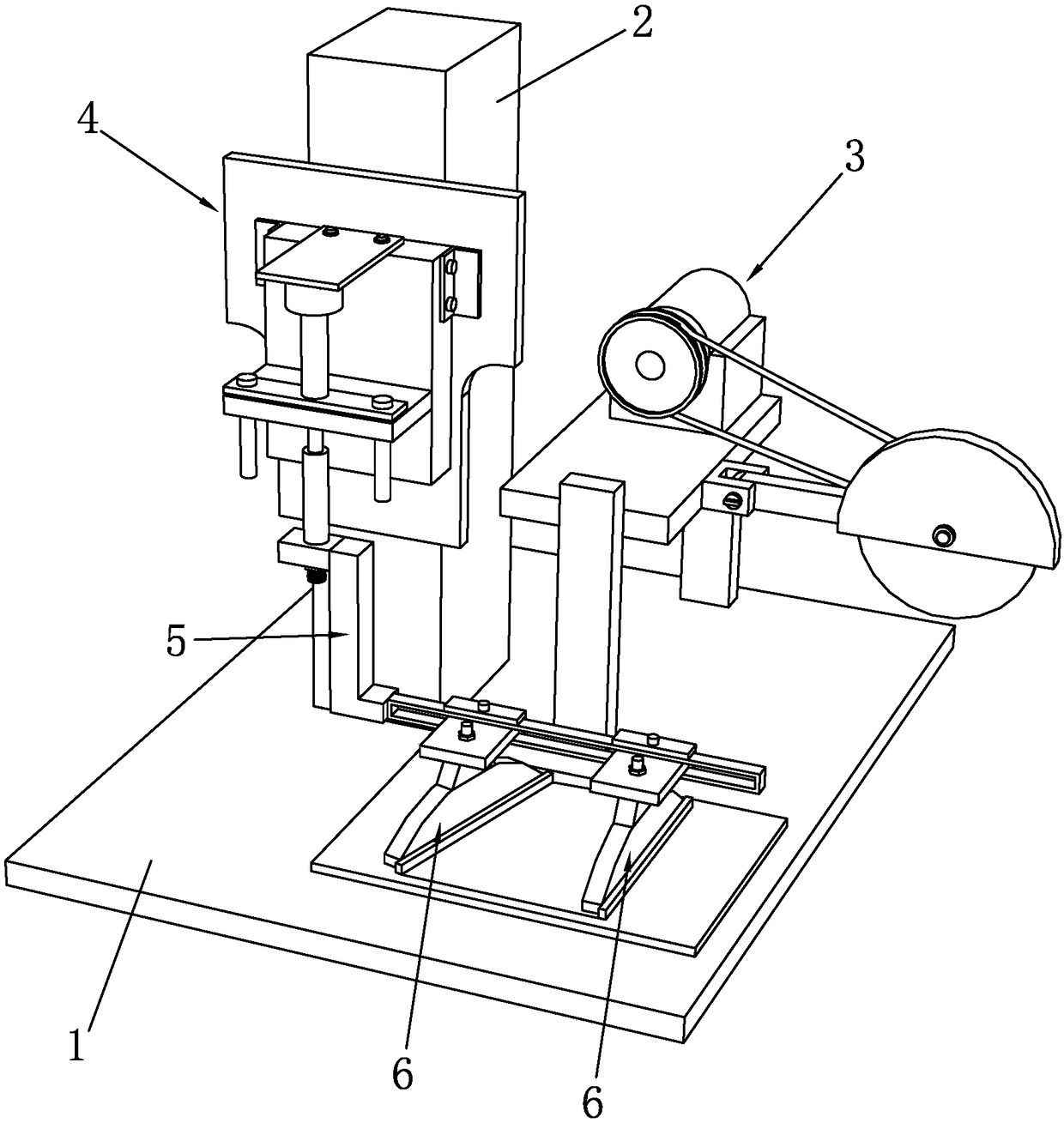

[0026] Such as Figure 1 to Figure 7 Shown is a cutting device for an aluminum plate of a range hood according to the present invention, which includes a base 1 , a supporting body 2 and a cutting device 3 , and the supporting body 2 and the cutting device 3 are both arranged on the base 1 .

[0027] The support body 2 is provided with a buffer control frame 4, and the buffer control frame 4 is provided with a drive mechanism, and an adjustment mechanism 5 is installed at the bottom of the drive mechanism, and the adjustment mechanism 5 is provided with two sets of aluminum plate cutting line setting mechanisms 6.

[0028] The aluminum plate cutting line setting mechanism 6 includes a sliding plate 7 and a lower pressing plate 8 , and the sliding plate 7 is slidably connected to the adjustment mechanism 5 . The sliding plate 7 is provided with a limiting end portion 9 , and the limiting end portion 9 is provided with a locking member 10 , and the locking member 10 is locked on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com