Cyclone dust collector

A vacuum cleaner and cyclone technology, applied in the field of cyclone vacuum cleaners, can solve the problems of poor integrity and portability, unfavorable cleaning, etc., and achieve the effects of good sealing, easy cleaning, and good integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

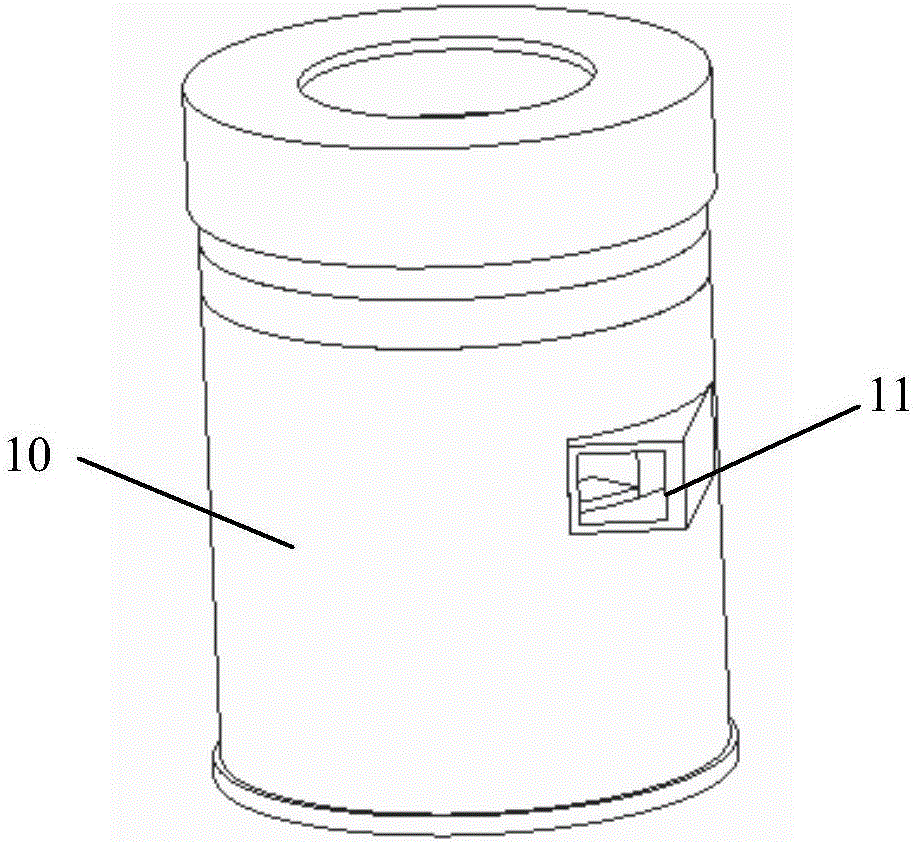

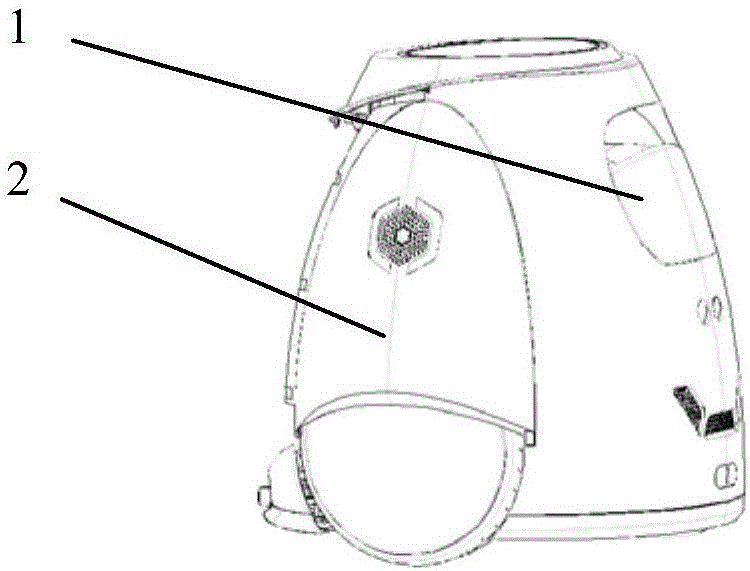

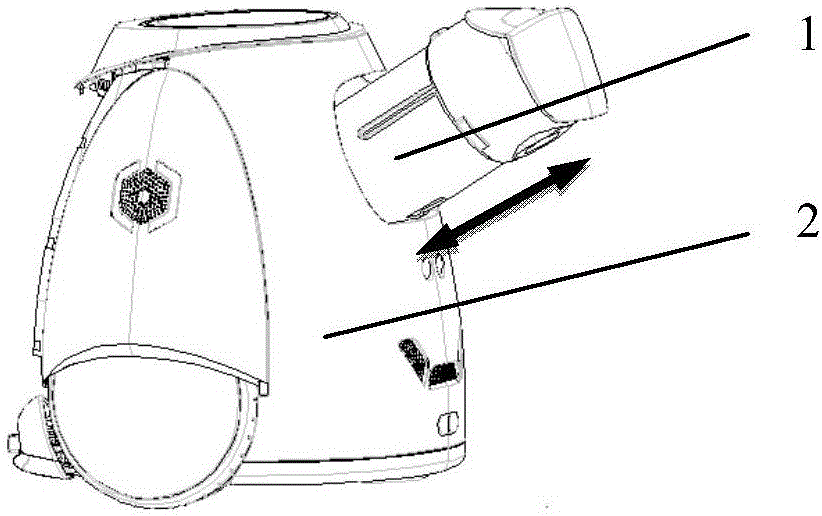

[0034] Such as Figure 2 to Figure 10 The cyclone vacuum cleaner shown includes a dust bucket 1, a housing 2 and a dust suction pipe 3. Both the dust bucket 1 and the dust suction pipe 3 are detachably installed inside the housing 2, and the inside of the housing 2 is inclined to accommodate dust. The cavity of the bucket 1, the cavity intersects with the housing 2 to form an entrance for the dust bucket 1 to be inserted into. The extension direction of the chamber forms a certain angle with the axis perpendicular to the bottom surface of the housing 2. When the temperature ranges from 60°C to 60°C, the dust bucket 1 is easier to insert into or pull out from the chamber. The insertion direction is as follows: image 3 indicated by the middle arrow. The shape of the outer wall of the dust bucket 1 ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap