Paint-coating device

A coating device and coating technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of declining coating quality, uneven coating, and waste of coating, so as to avoid the degradation of coating quality and avoid uneven paint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

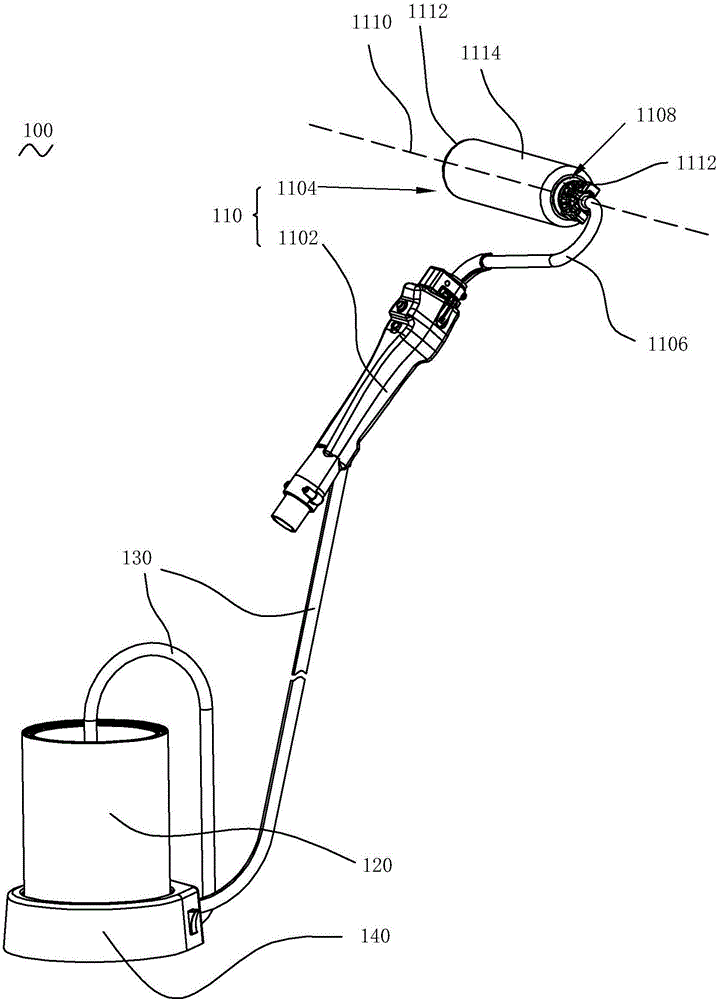

[0061] refer to figure 1 As shown, in an embodiment of the present invention, the paint application device 100 includes a handle 1102 for holding and a paint brush assembly 1104 . Handle 1102 and paint brush assembly 1104 are detachably connected.

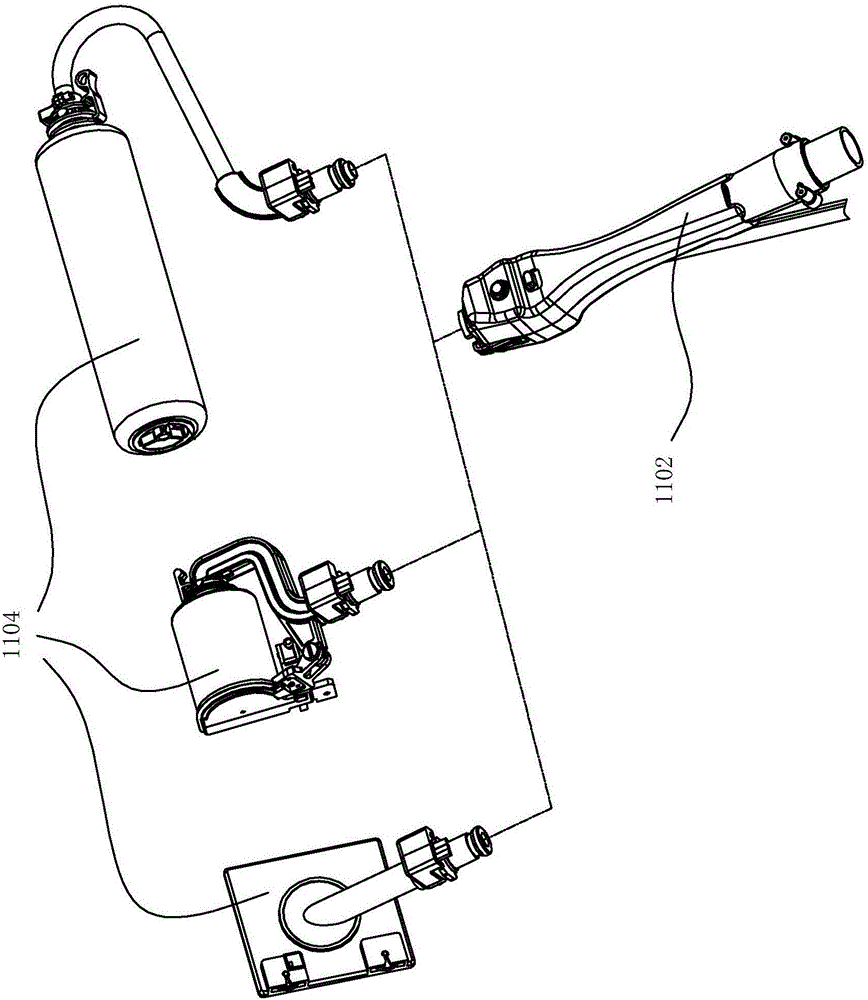

[0062] refer to figure 2 As shown, the paint application assembly 1104 comes in a variety of different types, each of which is detachably connected to the handle 1102 .

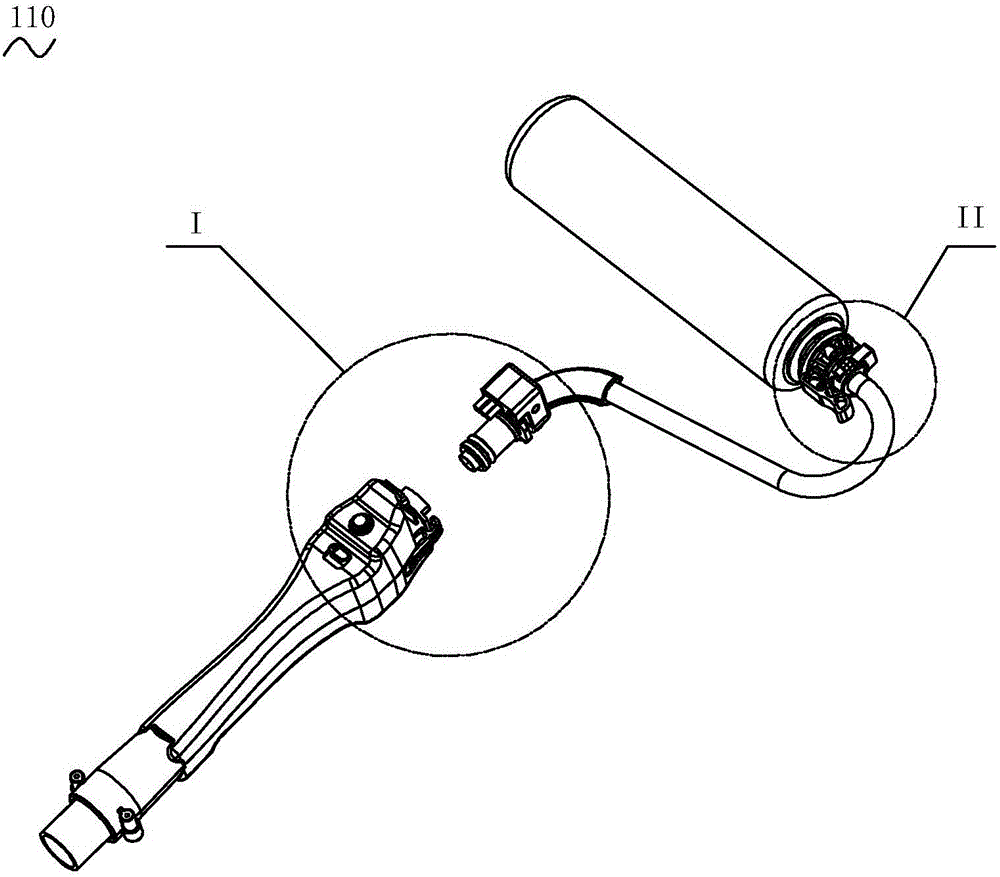

[0063] further reference image 3 and Figure 4 As shown, paint brush assembly 1104 includes a support shaft 1106 and a brush member 1108 . The support shaft 1106 is hollow, and one end is detachably mounted to the handle 1102 . Preferably, a sealing ring 1116 is provided at the joint between the support shaft 1104 and the handle 1102 to prevent paint leakage. A locking assembly 1118 is provided at the joint between the support shaft 1104 and the handle 1102 for fixing the support shaft 1104 and the handle 1102 to prevent the two from being disengaged. In ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap