A special hacksaw device

A hacksaw and guide rail technology, which is applied in the direction of sawing machine, metal sawing equipment, metal processing equipment, etc., can solve the problems of affecting sawing accuracy, saw blade breakage, and reducing the efficiency of sawing metal, so as to reduce the number of times to replace saw blades, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

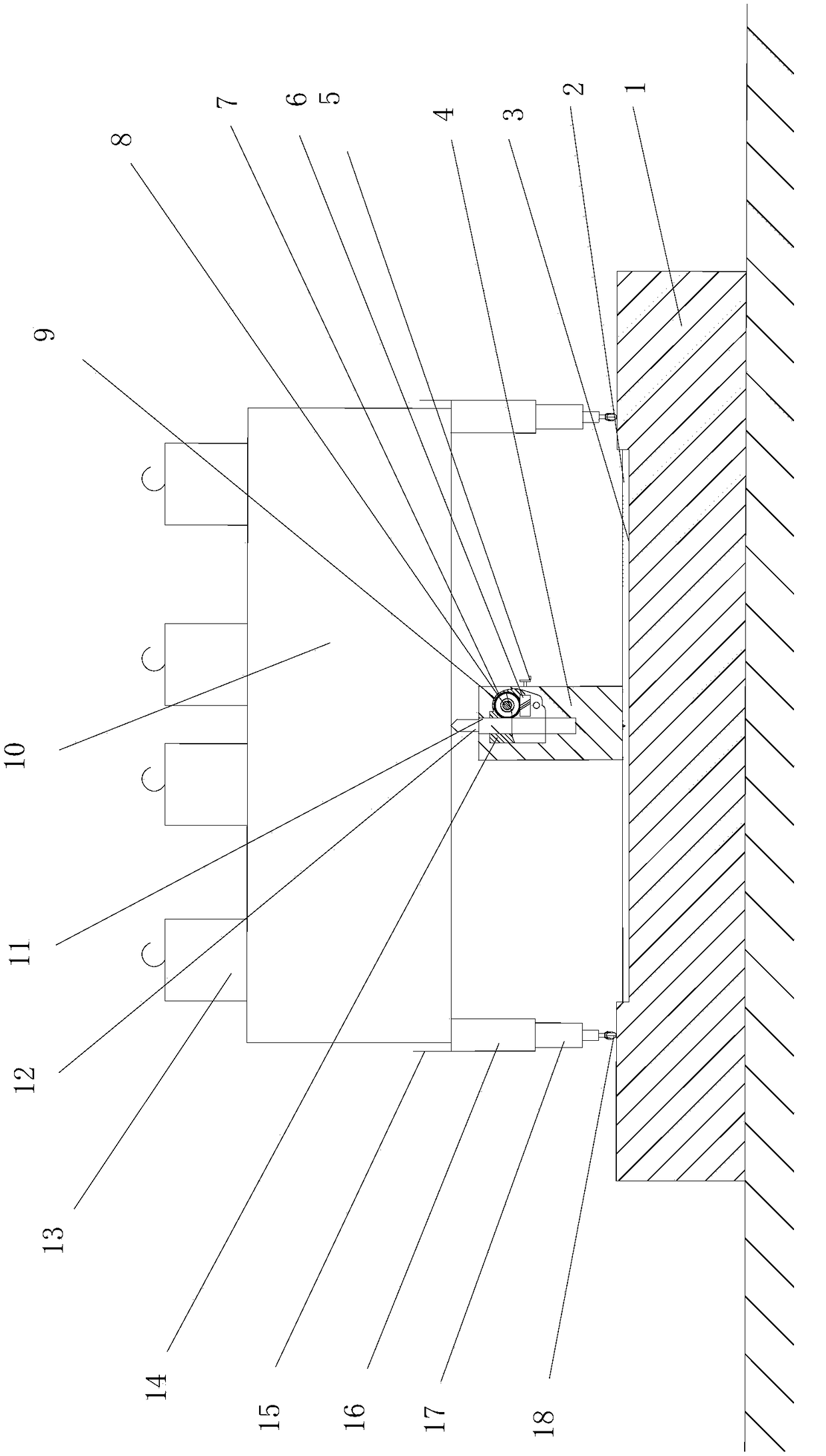

[0015] Such as figure 1 As shown, a special hacksaw device provided by the present invention includes a base 1, a guide rail 3, a fixing mechanism for a hacksaw 12, and a loading vehicle with a synchronous lifting function. The guide rail 3 is arranged on the horizontal upper surface of the base 1. The cart can move on the upper surface of the base 1. The fixing mechanism of the hacksaw 12 is arranged on the guide rail 3 and moves along the guide rail 3 to cut the material 10 placed on the cart. The fixing mechanism of the hacksaw 12 includes a slider 4 , hand wheel 5, worm 6, worm wheel 7, shaft 8, gear 9, rack 11, bearing 14 and hacksaw 12, slider 4 moves along guide rail 3, worm 6 is arranged on slider 4 and is connected with worm wheel 7 Transmission connection, the hand wheel 5 is set at one end of the worm 6 and the worm 6 is driven to ro...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap