Forming method of scroll spring and forming device of scroll spring

A forming device and a technology for a scroll spring, which are applied in the field of machining, can solve the problems of difficulty in processing the scroll spring, and achieve the effects of simple structure, low cost and wide processing range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

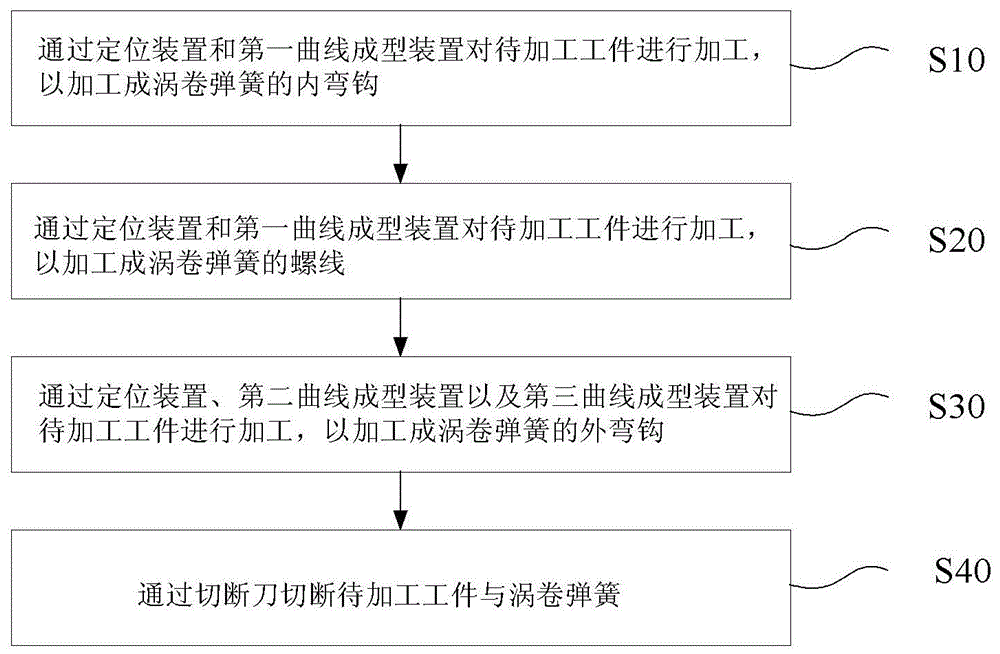

[0051] Such as figure 1 , figure 2 and Figure 16 As shown, the forming method of the scroll spring of the present embodiment includes the following steps:

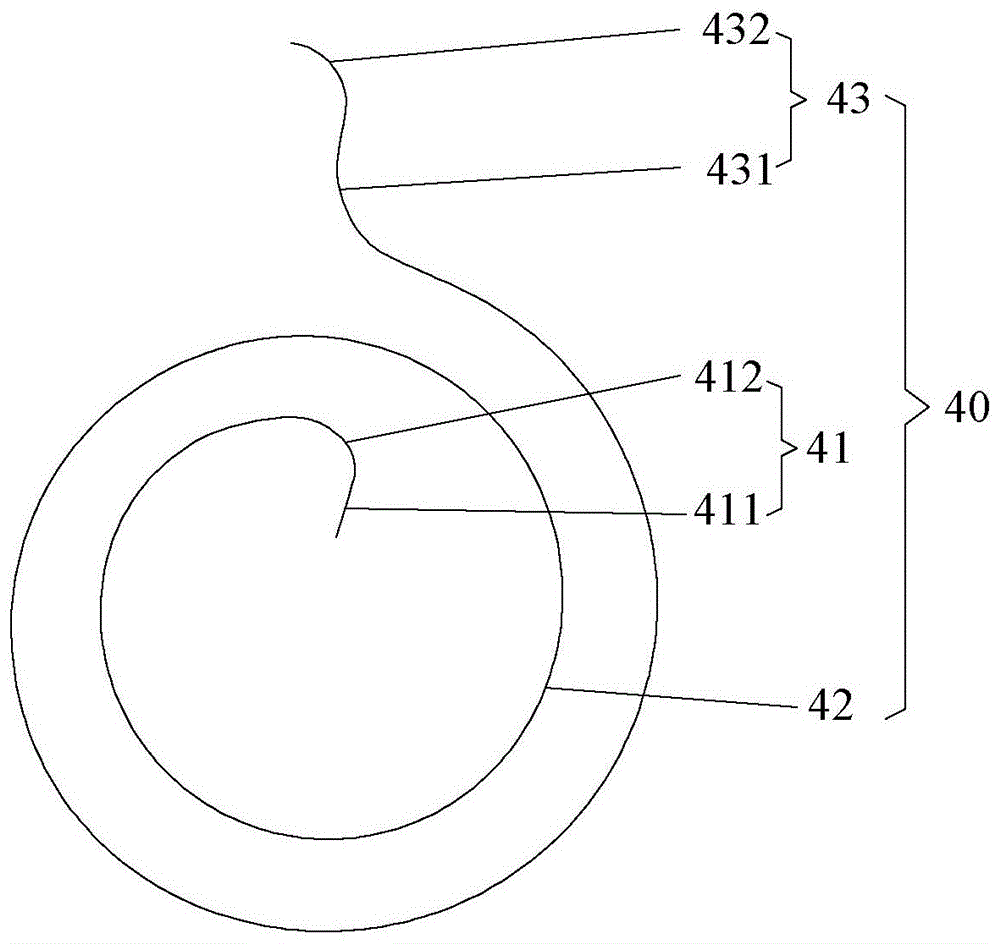

[0052] Step S10: Process the workpiece 30 to be processed by the positioning device 10 and the first curve forming device 20 to process the inner hook 41 of the scroll spring 40,

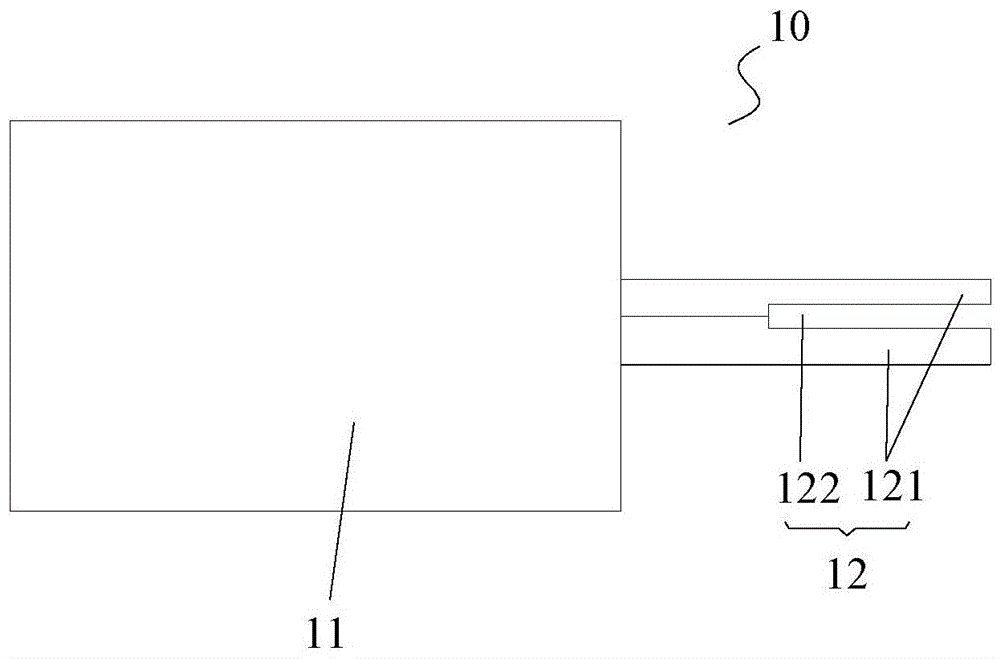

[0053] Among them, such as Figure 3 to Figure 5 As shown, the positioning device 10 includes a first base 11 and a positioning head 12. The positioning head 12 is arranged on the first base 11. The positioning head 12 includes two positioning plates 121 arranged oppositely. The space forms a through groove 122 for passing the workpiece 30 to be processed,...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap