A built-in quick-connect device

An embedded, transfer block technology, applied in the direction of launch/drag transmission, can solve the problems of external structure and excessive cross-sectional area, reduce buffer requirements, solve buffer problems, reduce mass and transmission. The effect of rushing the request

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Preferred embodiments of the present invention will be specifically described below in conjunction with the accompanying drawings, wherein the accompanying drawings constitute a part of the application and are used together with the embodiments of the present invention to explain the principle of the present invention.

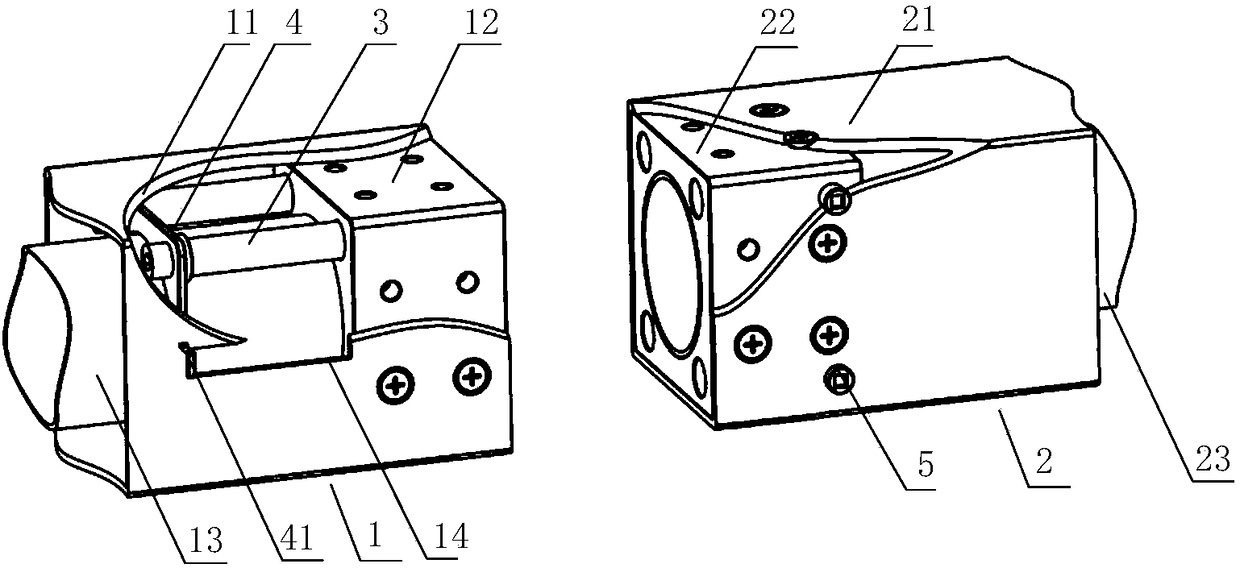

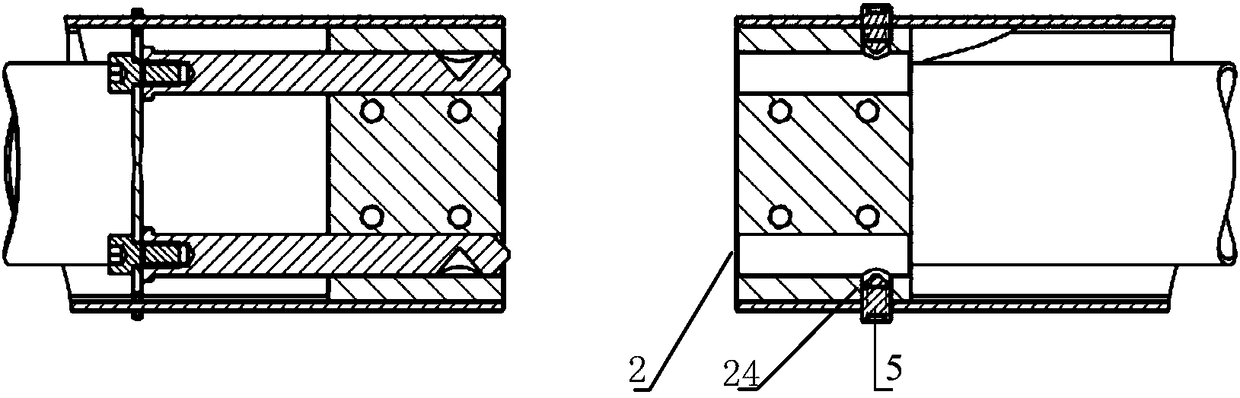

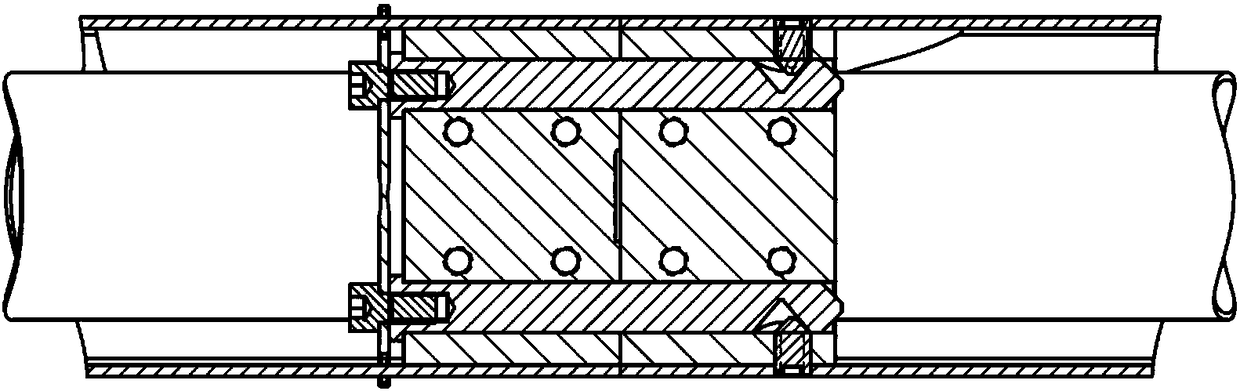

[0039] A built-in quick-connect device, the quick-connect device includes: a front adapter 1, a rear adapter 2, a quick-connect pin 3, a push plate 4, and a locking screw 5;

[0040] The front adapter 1 is composed of a square tube A 11, a front adapter block 12 and a cylinder A 13, and on the side where the front adapter 1 and the rear adapter 2 are connected, the end faces of the three are flush, and the front adapter block 12 is installed and It is fixed between the square pipe A 11 and the cylinder A 13, and each of the four sides of the front adapter block 12 is provided with four threaded holes, and the front adapter block 12 is connected and fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com