Cable drum fixing rack

A technology for fixing frames and cables, which is applied in thin material handling, conveying filamentous materials, transportation and packaging, etc. It can solve the problems of fixed frame structure, waste of resources, difficulty in meeting the universal application of cable reels, etc., to prevent Rotating loose, easy to use, convenient for on-site manual adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

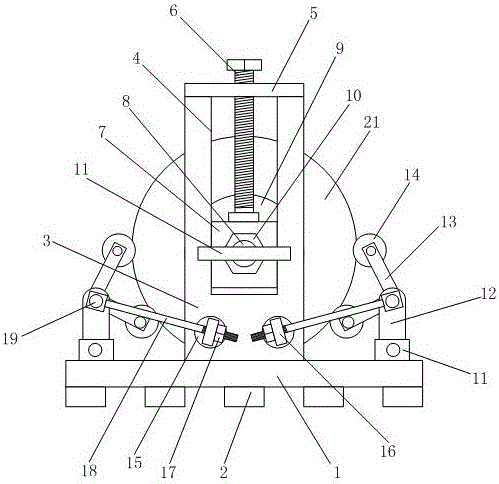

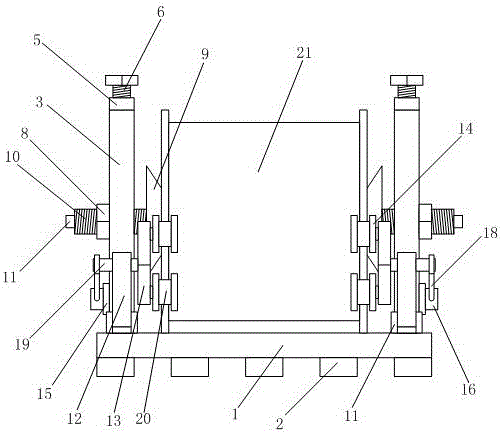

[0012] Such as figure 1 and 2 As shown, the cable reel fixing frame of the present invention includes: a base plate 1 , a support block 2 and two clamping mechanisms arranged symmetrically on the left and right sides of the base plate 1 .

[0013] Among them, the support blocks 2 are installed in an array on the lower side of the bottom plate 1; the clamping mechanism includes side plates 3, beams 5, lifting screws 6, sliders 7, extrusion screws 8, lock nuts 10, and conical extrusion heads 9 And rotating handle bar 11; Side plate 3 is vertically installed on the upper side of base plate 1; On side plate 3, be provided with a chute 4 vertically; Beam 5 is horizontally arranged at the upper end notch place of chute 4; Slider 7 Embedded in the chute 4, and can lift and slide along the chute 4; the lifting screw 6 is vertically screwed on the beam 5, and the lower end of the lifting screw 6 is rotatably installed on the slider 7; the extrusion screw 8 is threaded and screwed On ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com