A Suspension and Turning Capsule Drying Device

A drying device and flip-type technology, which is applied in the direction of drying, drying machine, heating device, etc., can solve the problems of capsule deformation, capsule outer surface hardening, adhesion, etc., to avoid uneven heating, avoid cumbersome inconvenience, and benefit Promoted app performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

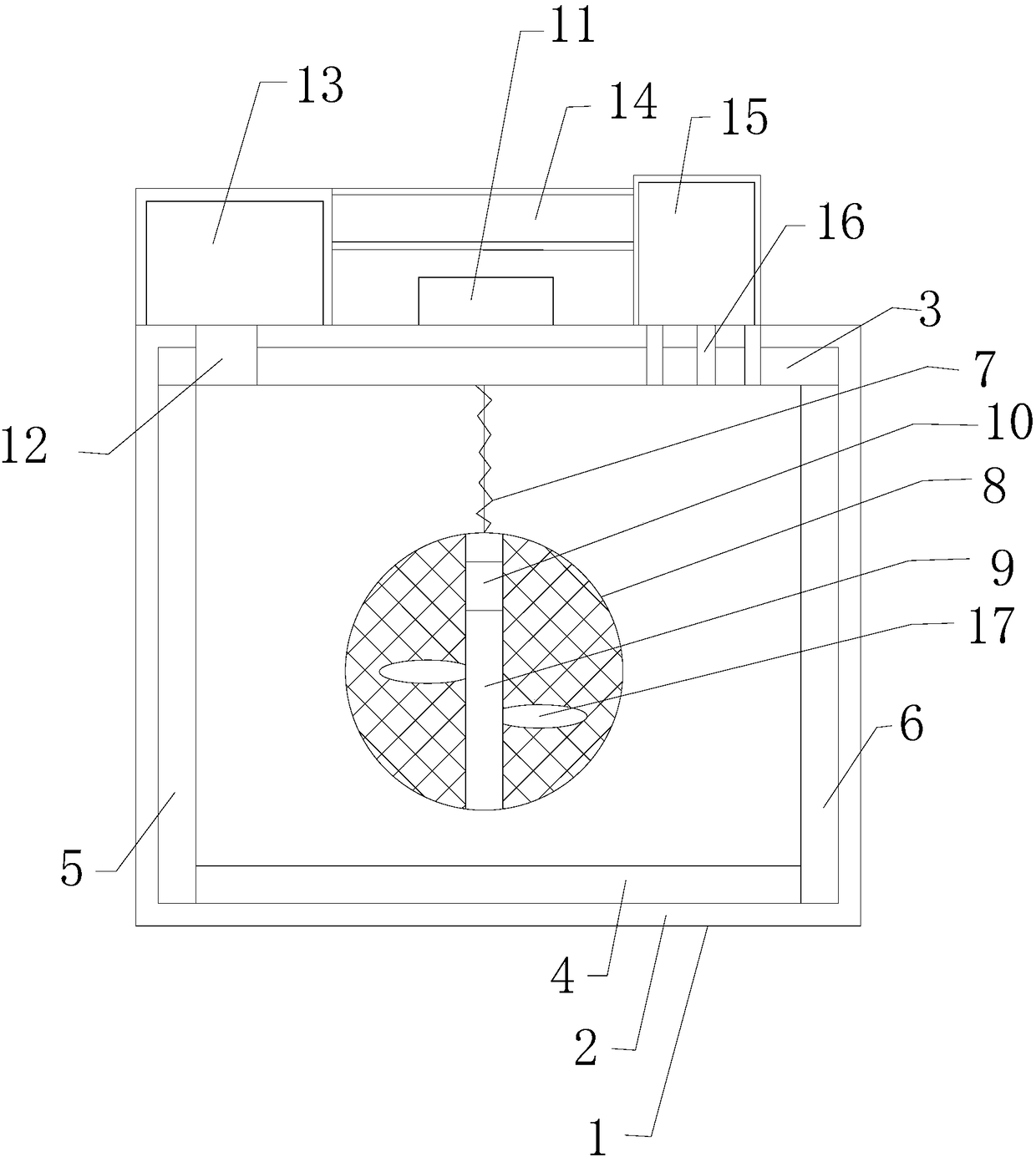

[0012] refer to figure 1 , a suspension flipping capsule drying device of the present invention, comprising a drying box 1, a heating wall 2, an upper electromagnetic plate 3, a lower electromagnetic plate 4, a left electromagnetic plate 5, a right electromagnetic plate 6, a protective shrinkage cable 7, a drying Suspension cage 8, temperature and humidity monitoring column 9, signal transmitter 10, control center 11, moisture exhaust air pipe 12, air pump 13, transmission pipe 14, filter drier 15, branch air intake pipe 16, the drying box 1 is set There is a heating wall 2, the top of the heating wall 2 is provided with an upper electromagnetic board 3, the bottom of the heating wall 2 is provided with a lower electromagnetic board 4, and the left side of the heating wall 2 is provided with a left electromagnetic board 5. The right side of the heating wall 2 is provided with a right electromagnetic plate 6, and the upper electromagnetic plate 3 is provided with a protective s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com