Induction type non-flip stop spot dotting tool and using method thereof

An inductive and tooling technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of reducing work efficiency, adding motors, bumping, etc., and achieve the effect of improving work efficiency and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

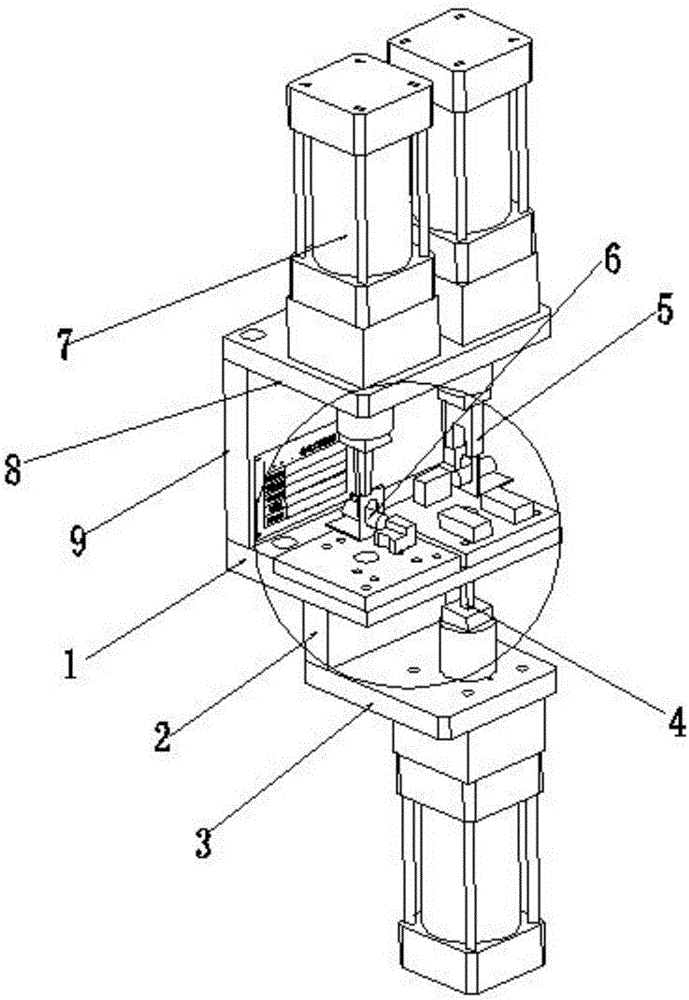

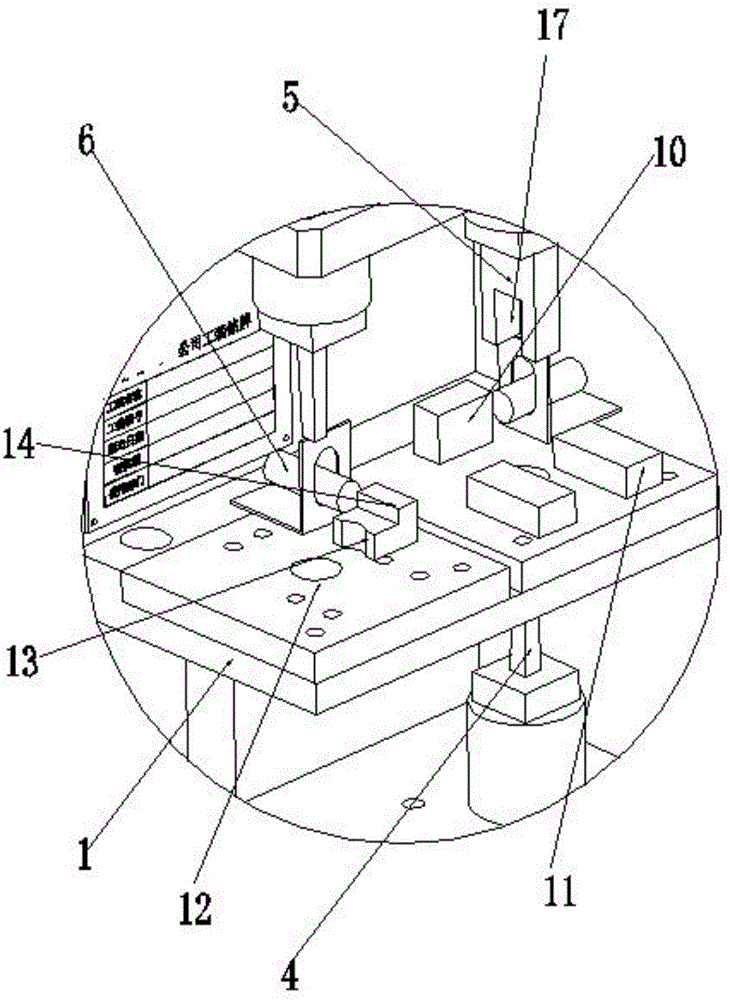

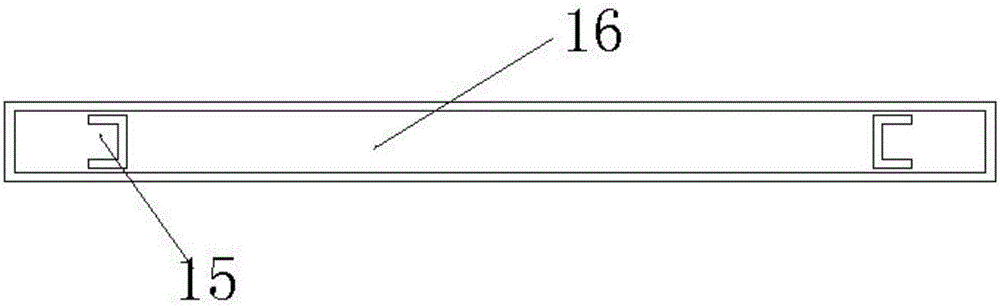

[0022] An inductive stop point tool that does not need to be turned over, the stop point tool includes a workbench 1 for placing guide rails, on the workbench 1 is provided with a stop point hole 12 for folding the stop point, on the workbench 1 There is a power device for hitting the stop point on the guide rail. The power device includes a block point gun 4 and a power cylinder 7 for providing power to the block point gun 4. The short guide rail stopper assembly and the long guide rail stopper assembly used to limit the long guide rail. A power device for blocking the short guide rail is provided in the vertical direction of the short guide rail placement position on the workbench. The vertical direction of the placement position of the upper long guide rail is provided with a power device for blocking the long guide rail. The long guide rail power device and the short guide rail power device are respectively located on both sides of the workbench 1, and the short guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com