Patents

Literature

63results about How to "Save time flipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

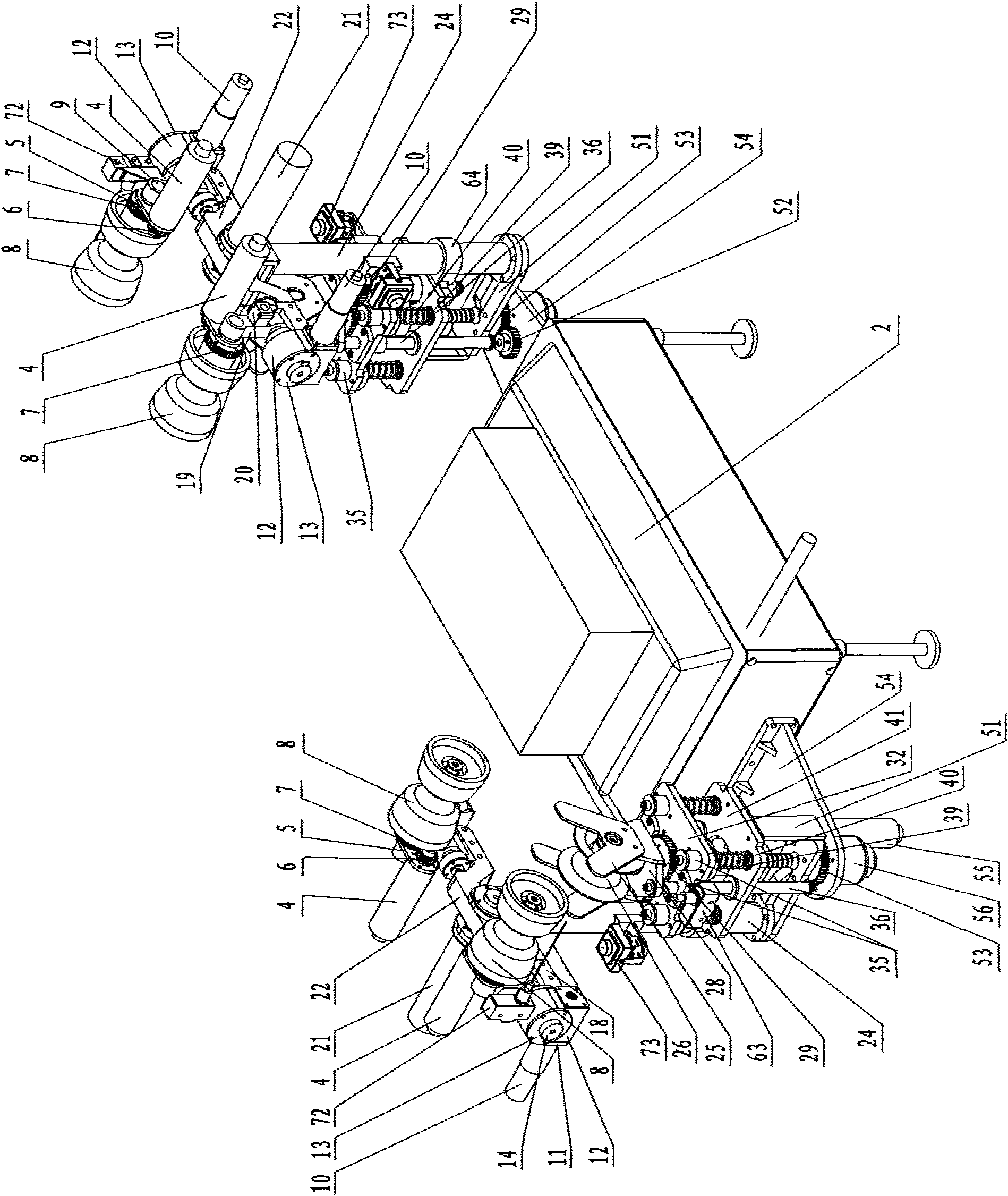

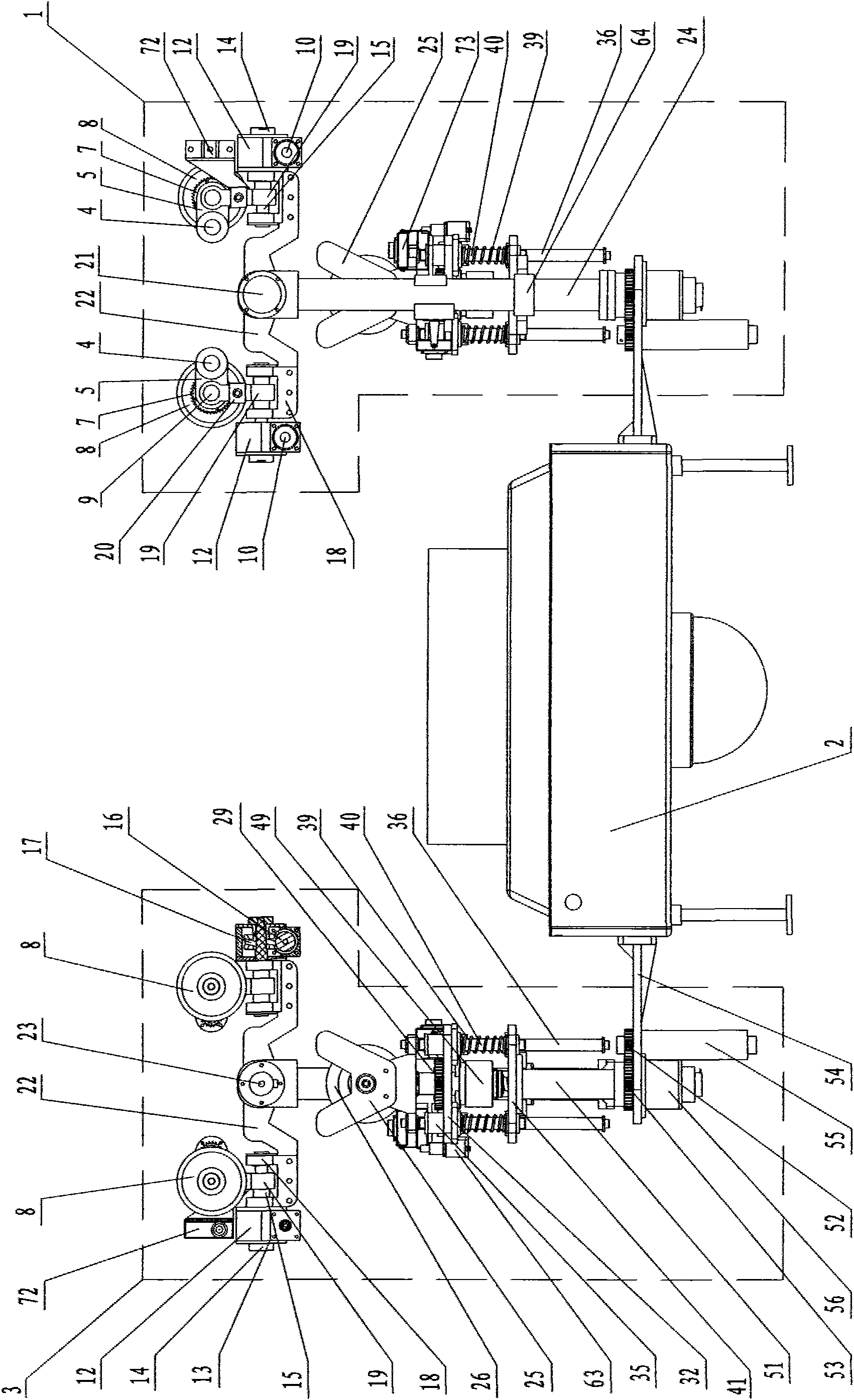

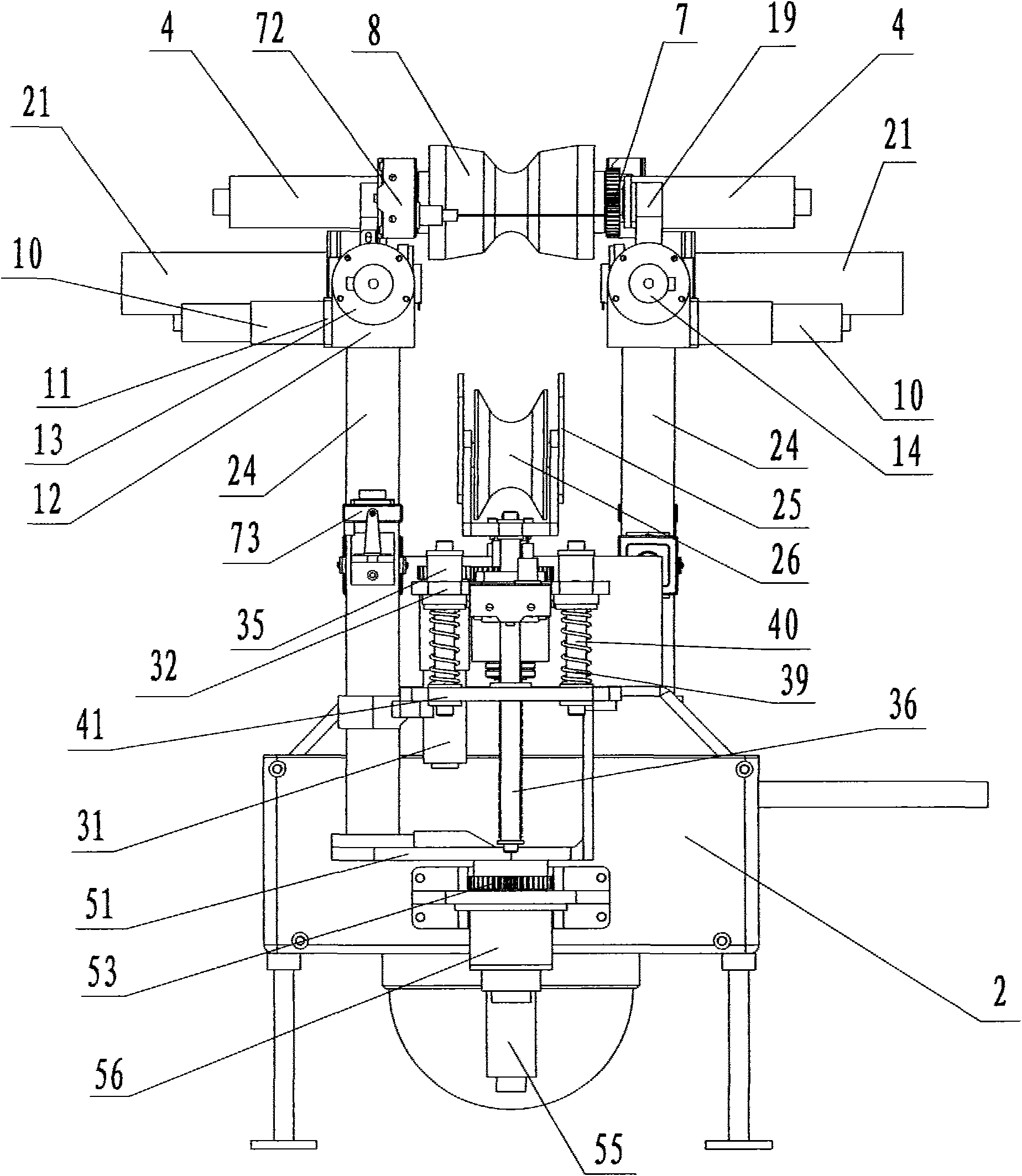

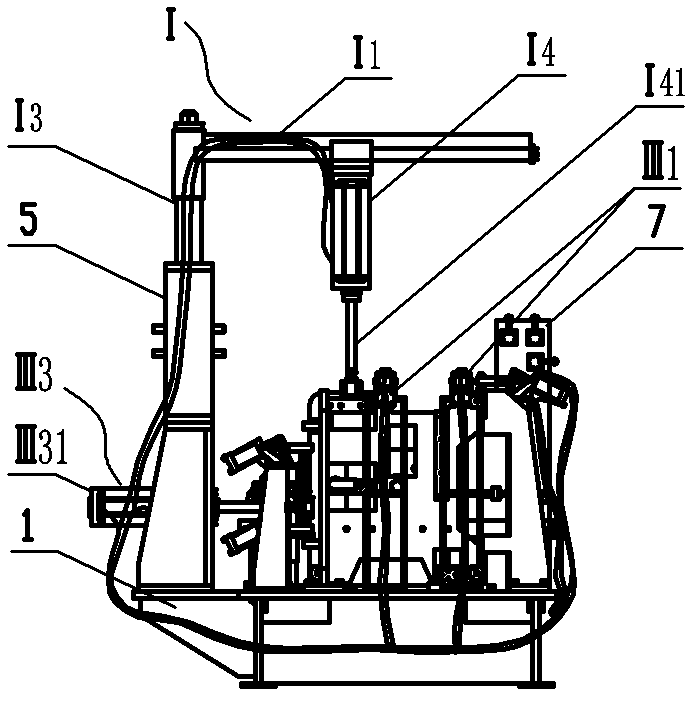

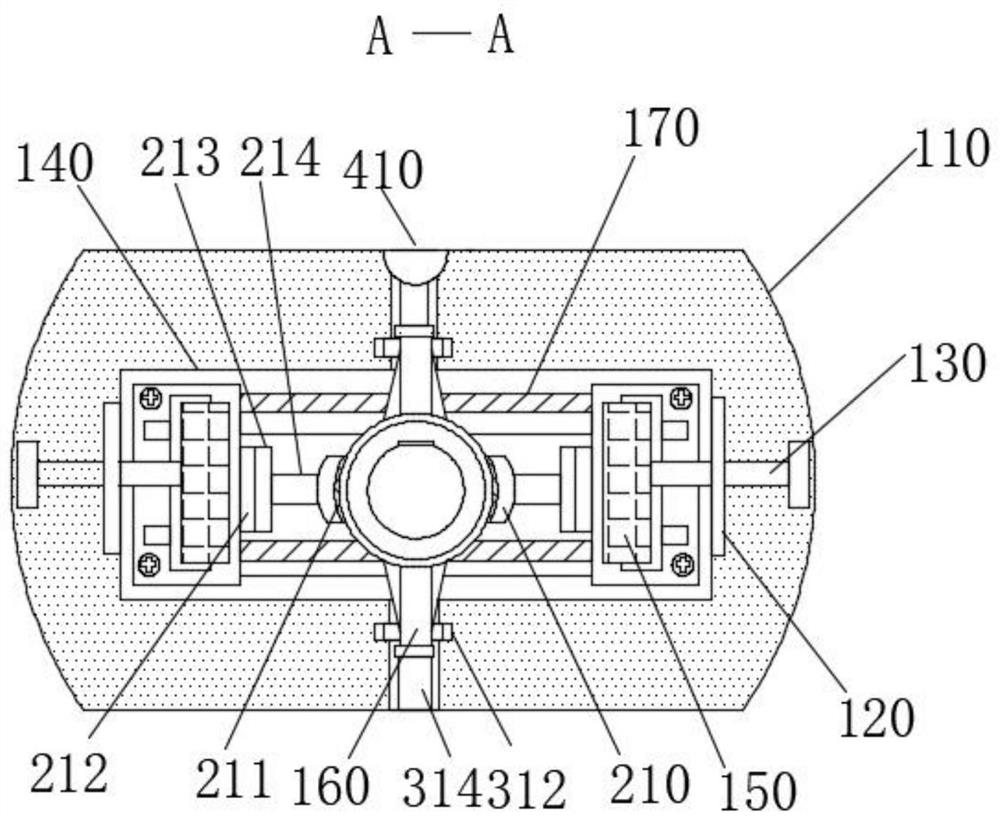

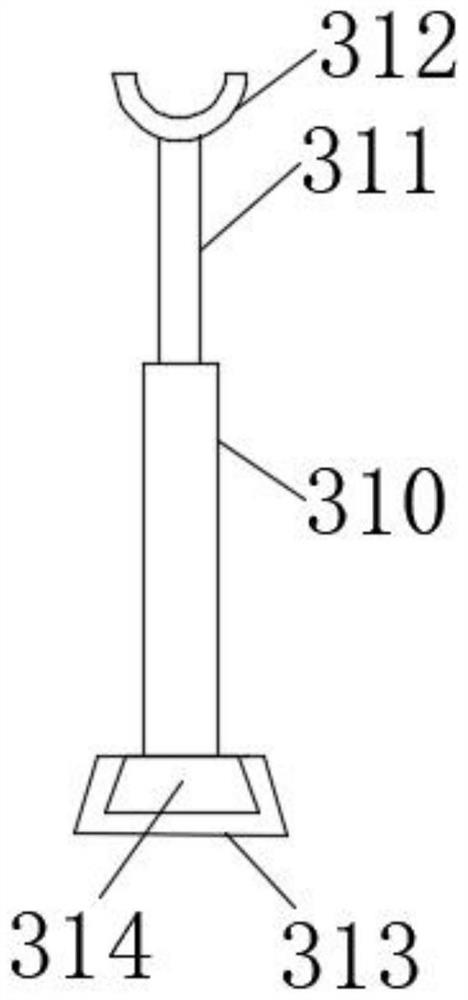

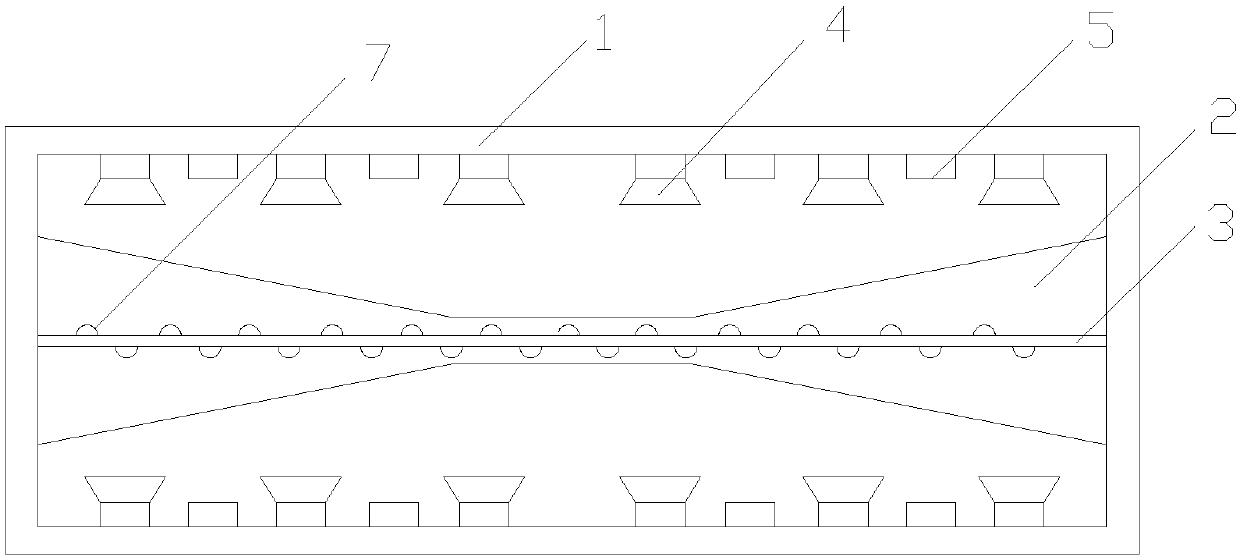

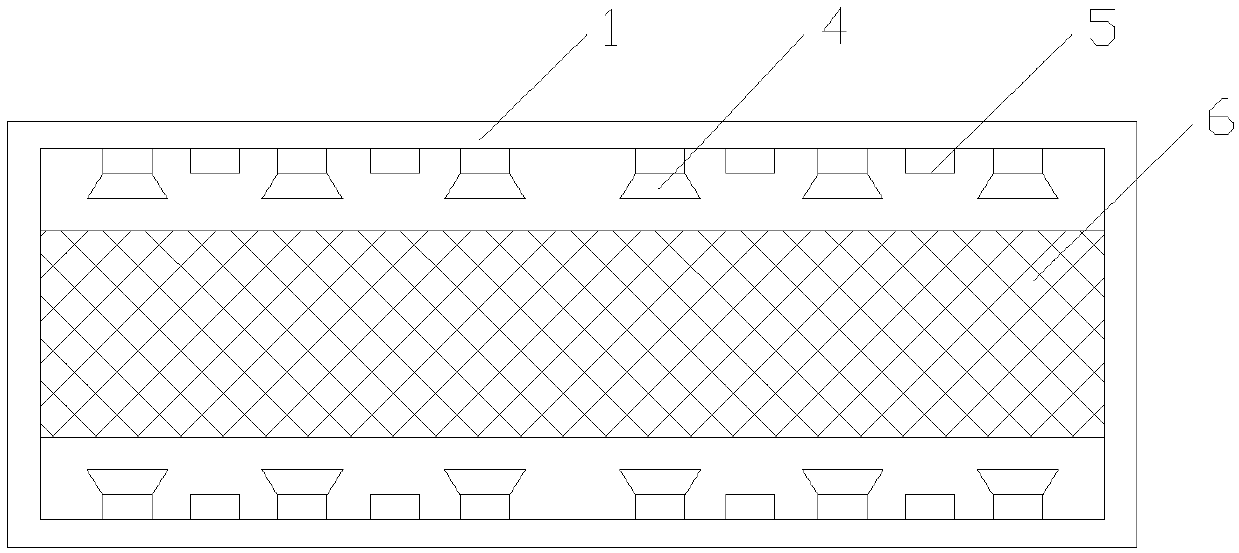

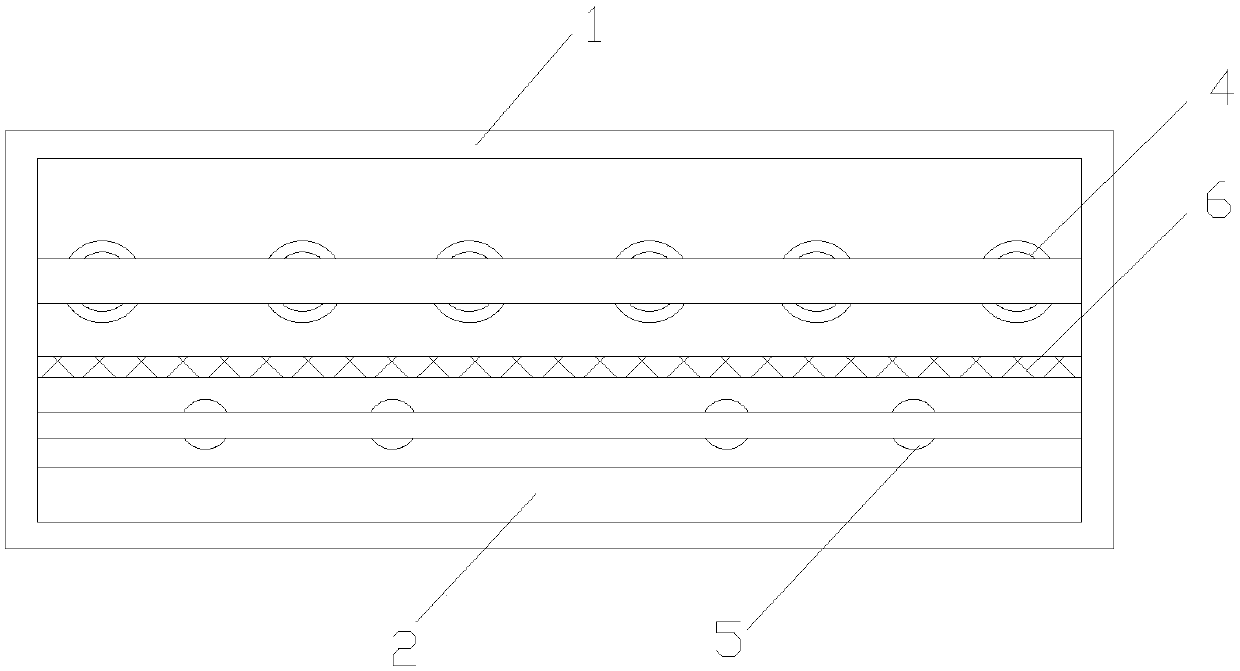

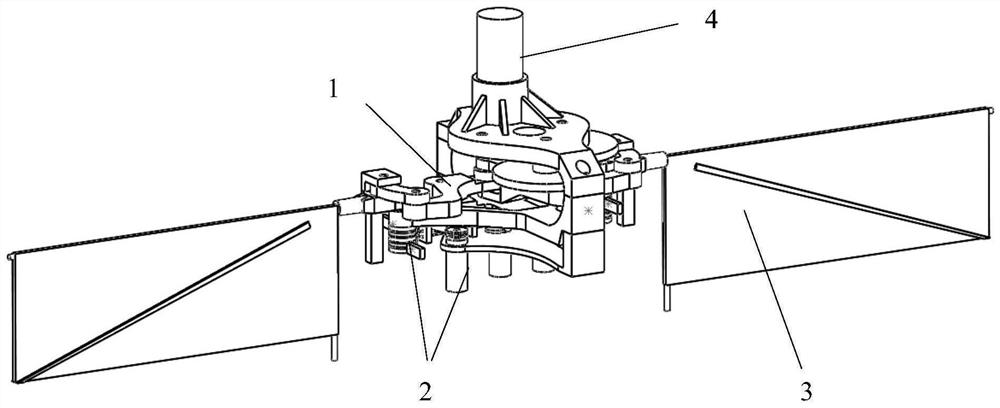

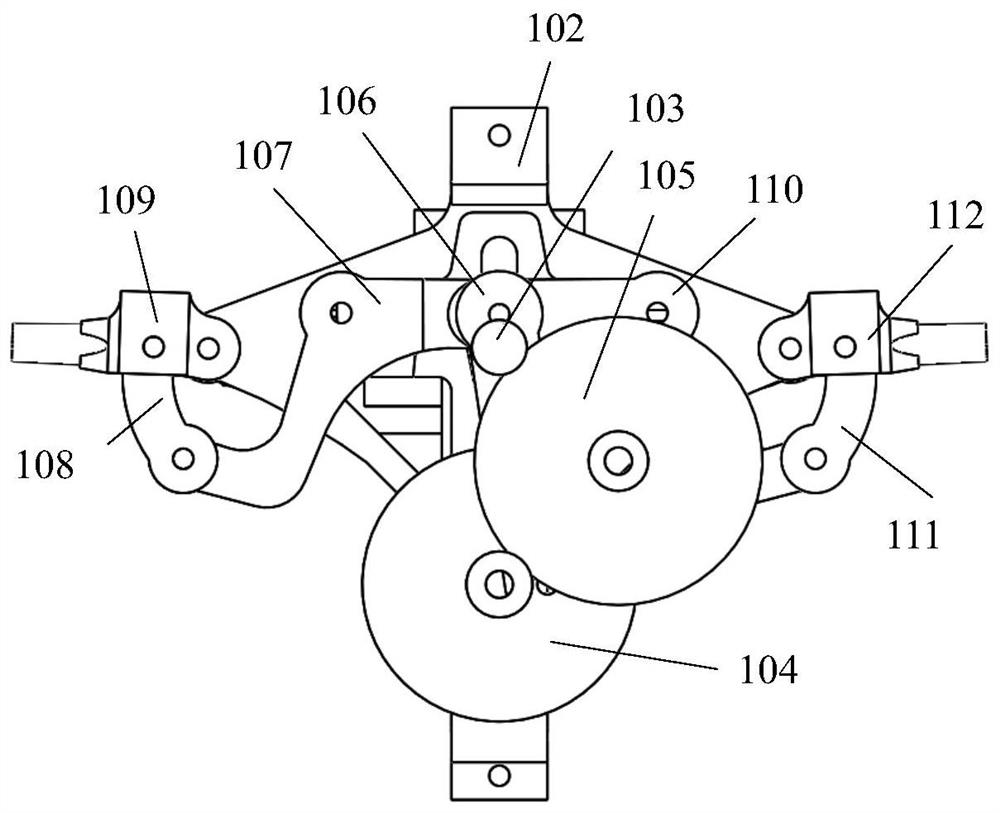

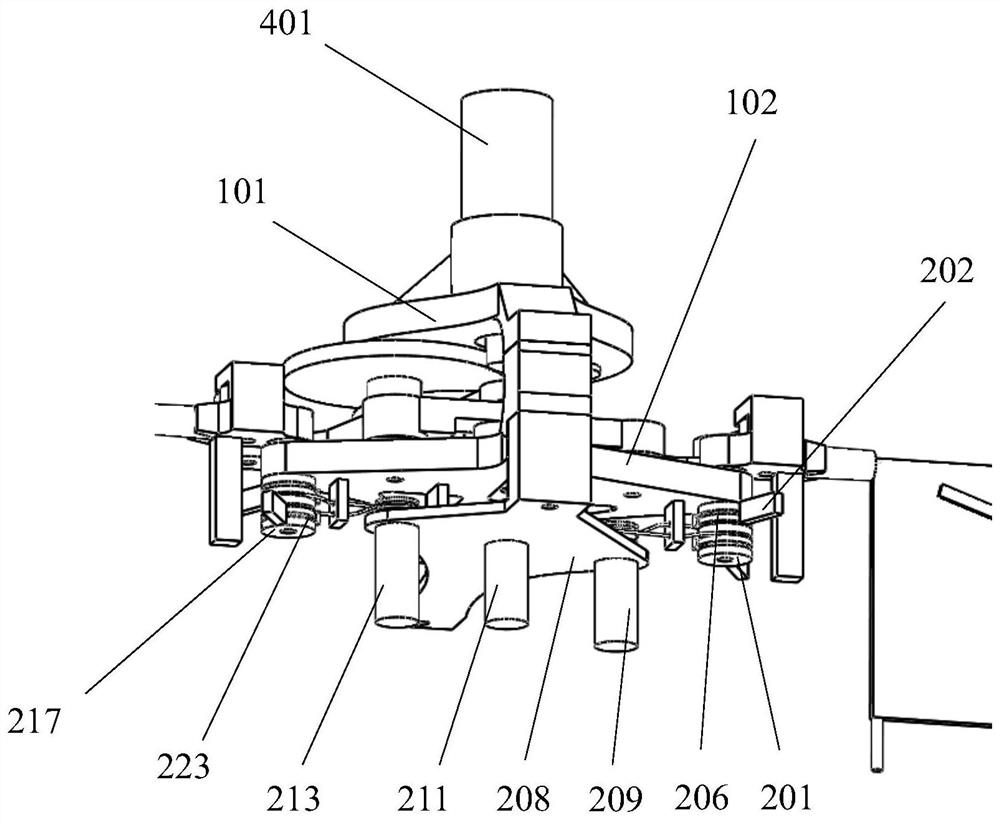

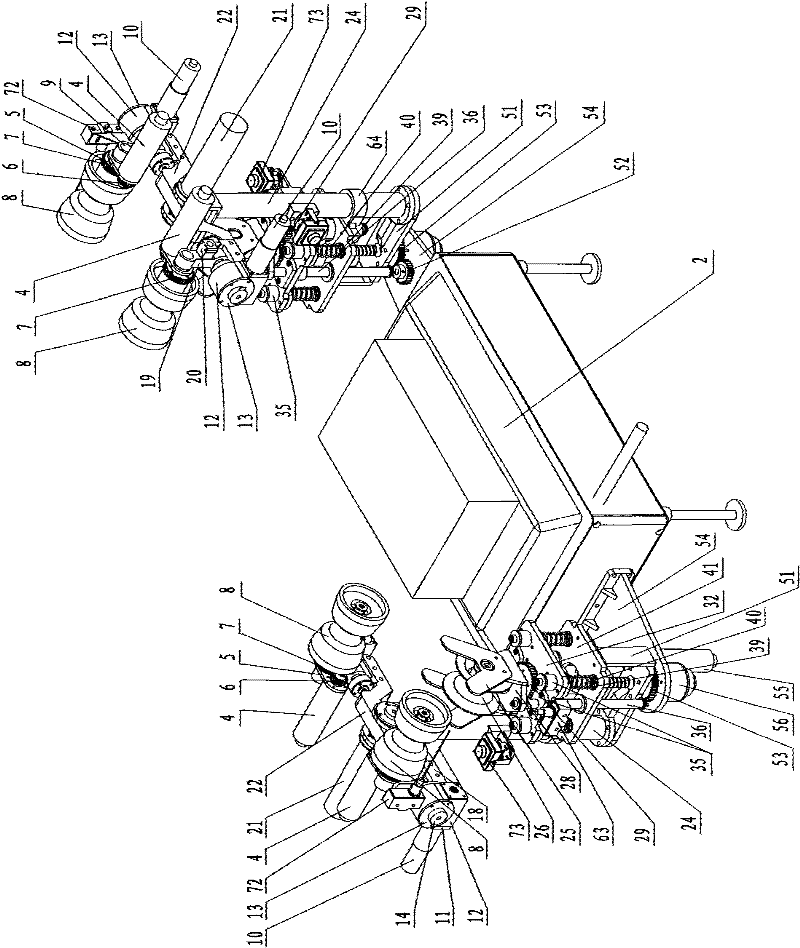

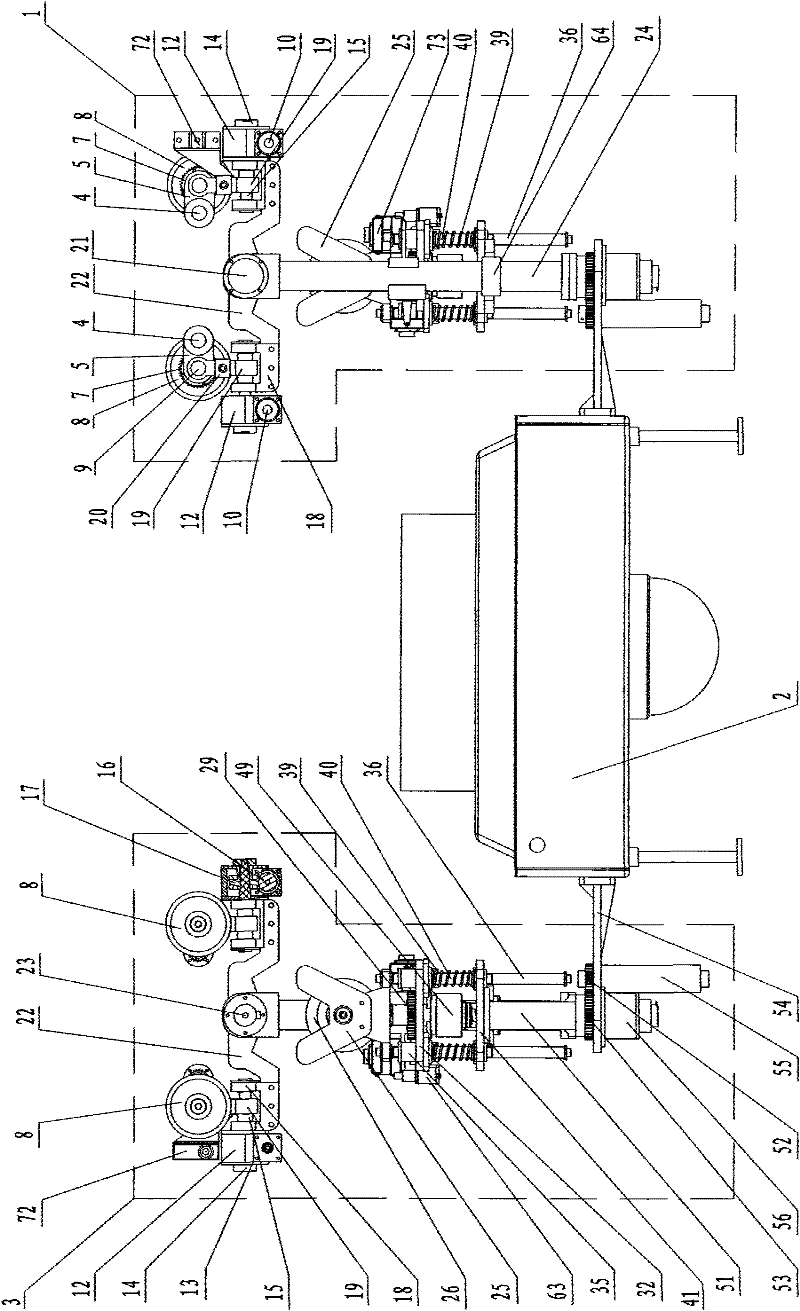

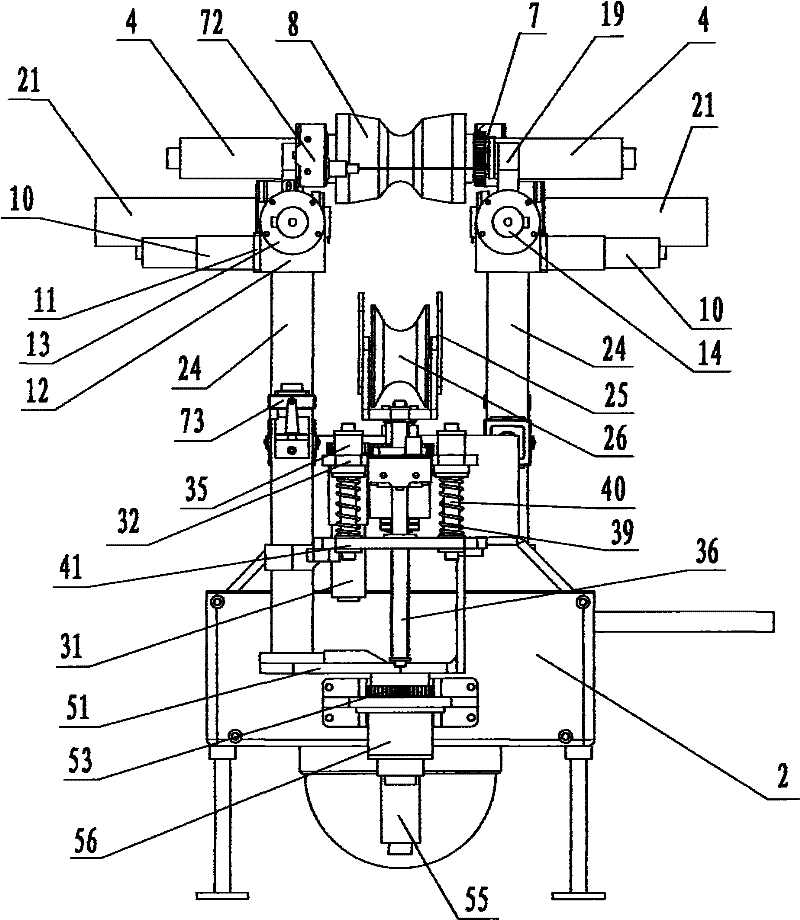

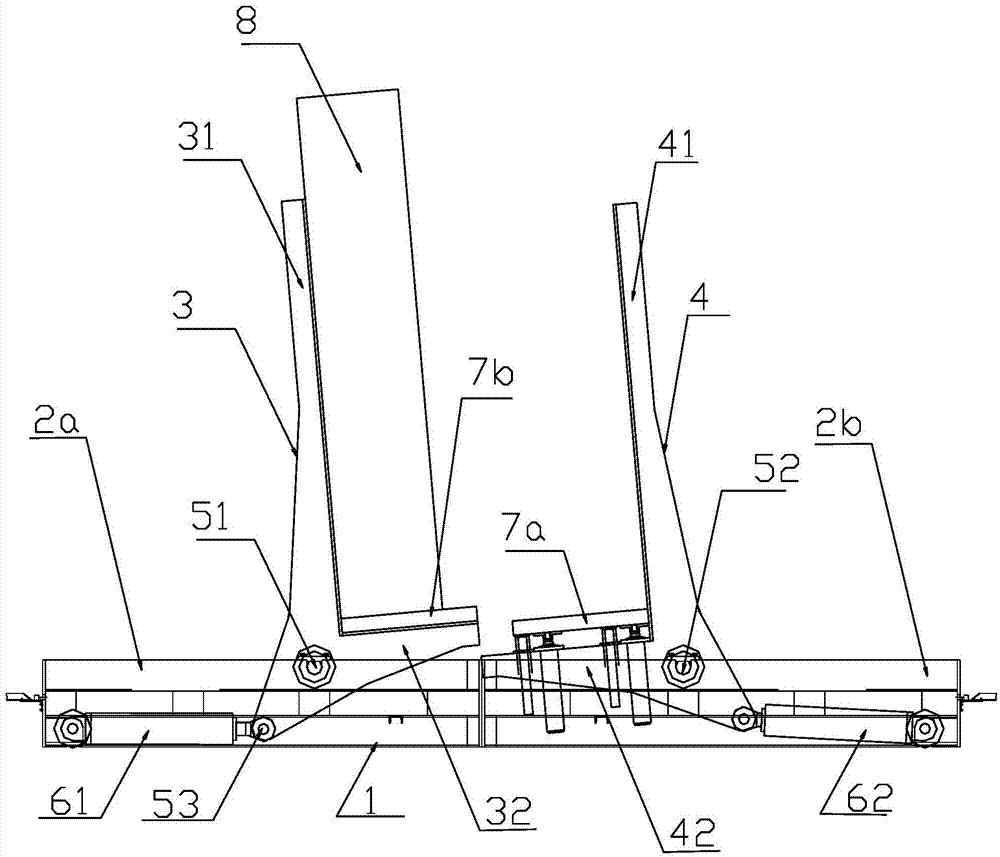

Double-arm four-wheel polling robot mechanism

The invention relates to a mobile robot, in particular to a double-arm four-wheel polling robot mechanism comprising a box body, a front arm mechanism and a rear arm mechanism, wherein the front arm mechanism and the rear arm mechanism are of the same structure and are respectively installed on the box body; each arm mechanism comprises travelling mechanisms, turnover mechanisms, an elevating gear, a clamping mechanism and a supporting arm, wherein one end of the supporting arm is connected with the box body, and the other end of the supporting arm is hinged with the elevating gear the two ends of which are respectively provided with the front turnover mechanism and the rear turnover mechanism; the front travelling mechanism and the rear travelling mechanism which can be turned over to the vertical state from the horizontal state are respectively connected to the output end of the front turnover mechanism and the output end of the rear turnover mechanism; the front travelling mechanism, the rear travelling mechanism, the front turnover mechanism and the rear turnover mechanism are linked with the elevating gear; and the clamping mechanism which is installed on the supporting arm and can clamp earth wires by moving up and down is arranged just below the front travelling mechanism and the rear travelling mechanism. The robot mechanism provided by the invention has the advantages of good safety protection performance, strong crawling and obstacle-detouring capability, large working space, wide application range and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

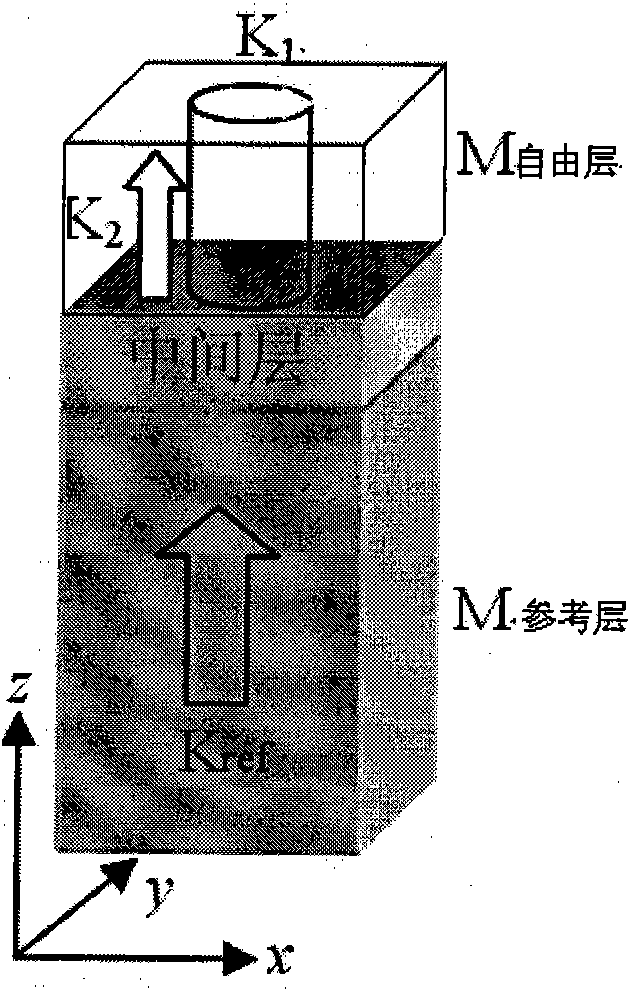

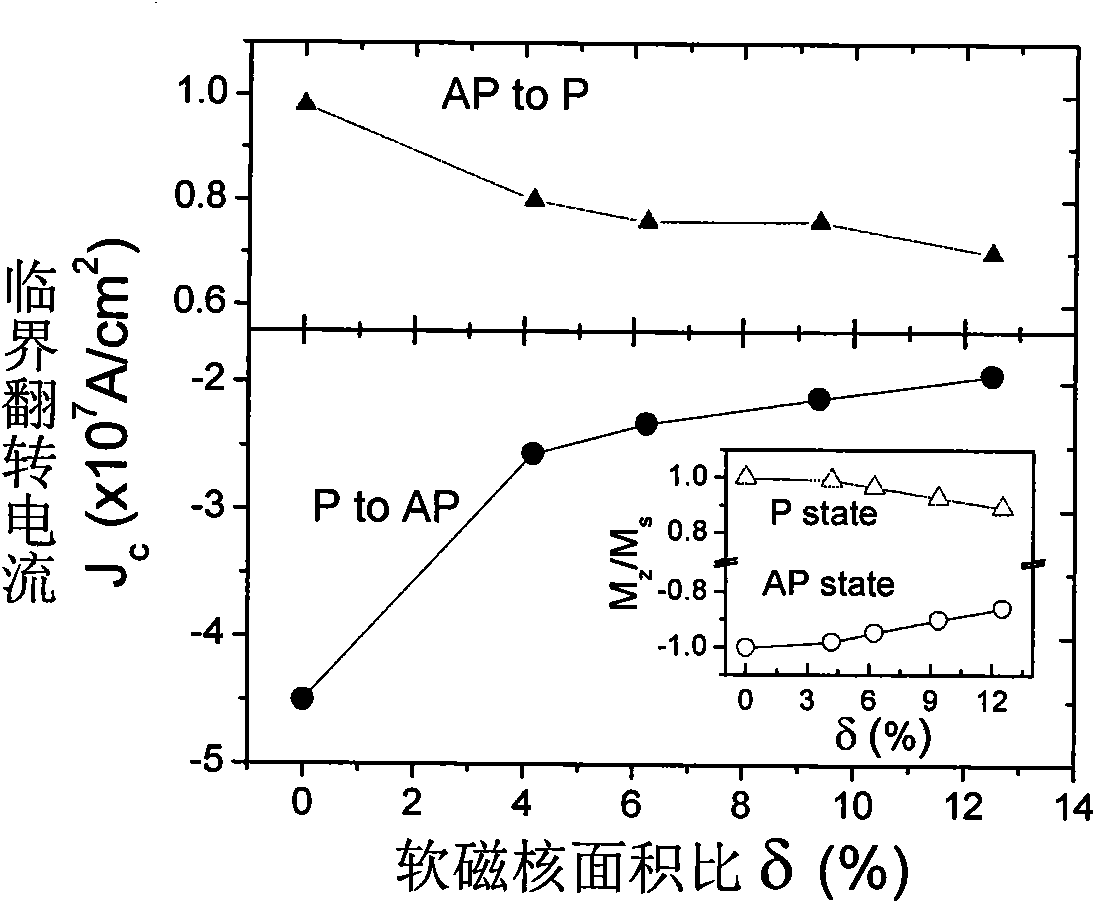

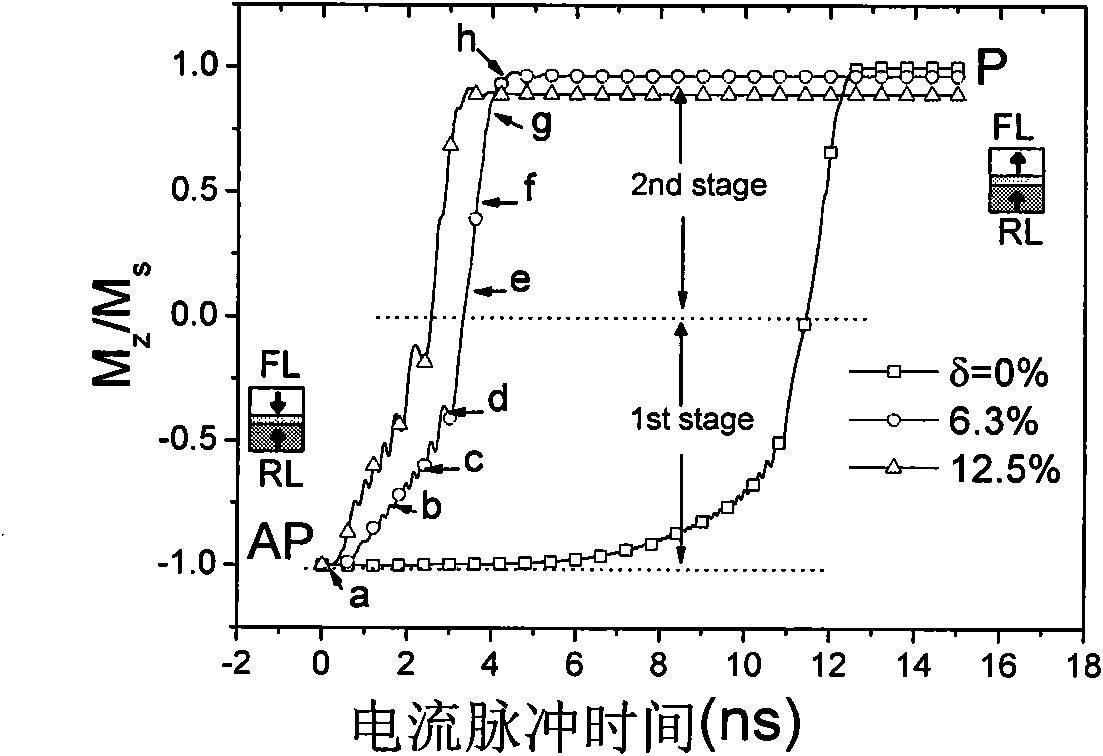

Perpendicular magnetic spin valve with nano soft magnetic core

InactiveCN101853919AIncrease asymmetryEfficient use ofMagnetic-field-controlled resistorsDigital storageMagnetic storageSpin valve

The invention belongs to the technical field of magnetic storage, in particular to a perpendicular magnetic spin valve with a nano soft magnetic core. In the structure of the spin valve, a magnetic reference layer and a free layer respectively adopt a [Co / Pt] multi-layer membrane structure and a [Co / Ni] multi-layer membrane structure with perpendicular magnetic anisotropy. A [NiFeCo] nano soft magnetic core with planar magnetic anisotropy is added in the free layer used for information storage through micro preparation or doping. The area of the nano core can be controlled to be 2-12 percent of the total area of the free layer without influence on signal storage. The micro-magnetic simulation of the nano spin valve device shows that compared with the ordinary perpendicular magnetic spin valve, the magnetization reversal current of the perpendicular magnetic spin valve with the nano core is greatly reduced, the reduction amplitude is up to 56.9 percent, the reversal time is reduced by 65.1 percent, and the strength asymmetry of the critical reversal current is greatly improved simultaneously. Therefore, the invention has significant application value in the research and development of the power-saving, self-spinning, high-capacity and rectangular magnetic random access memory MRAM.

Owner:FUDAN UNIV

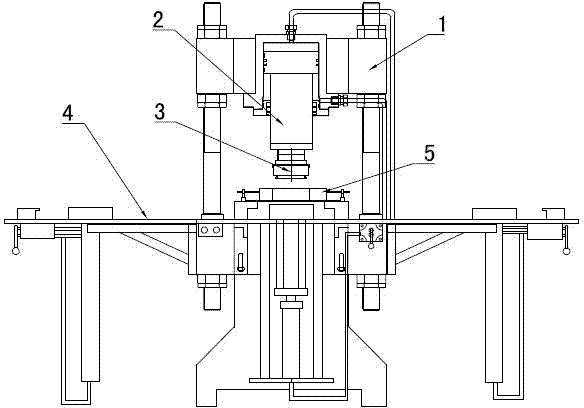

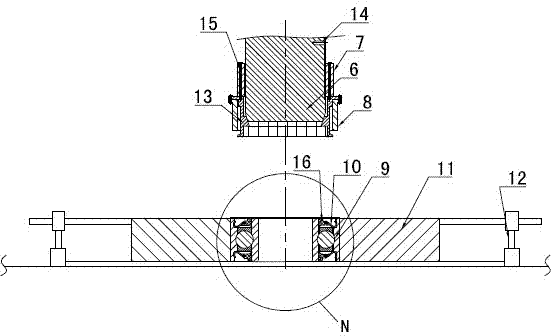

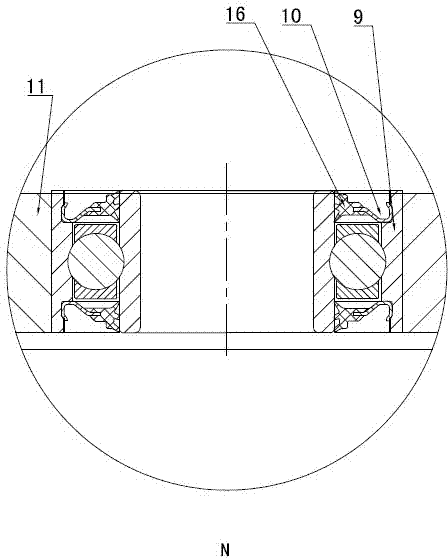

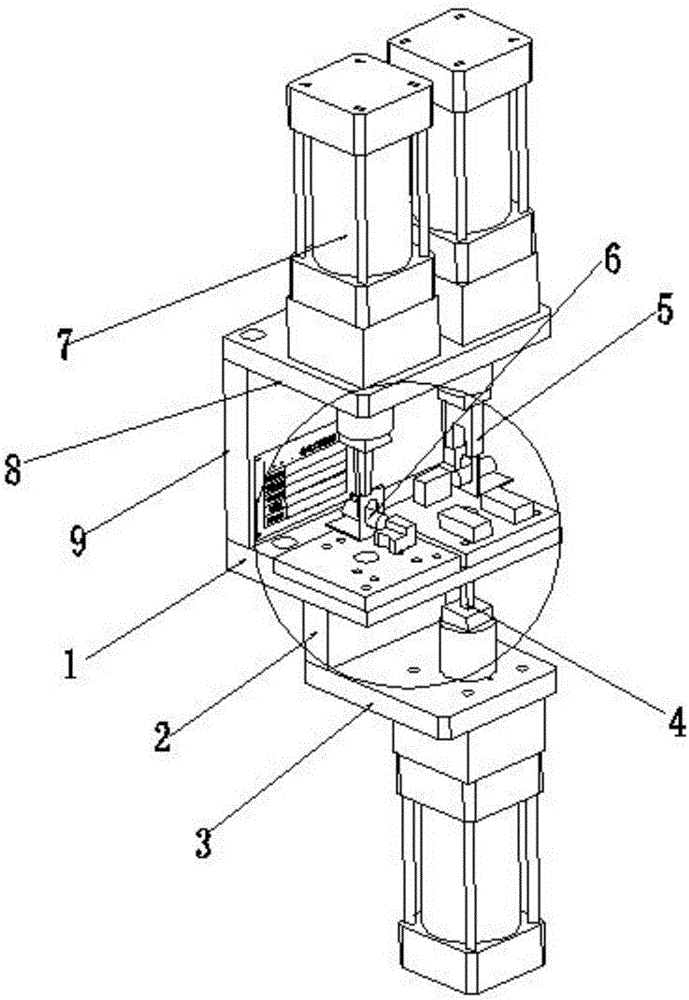

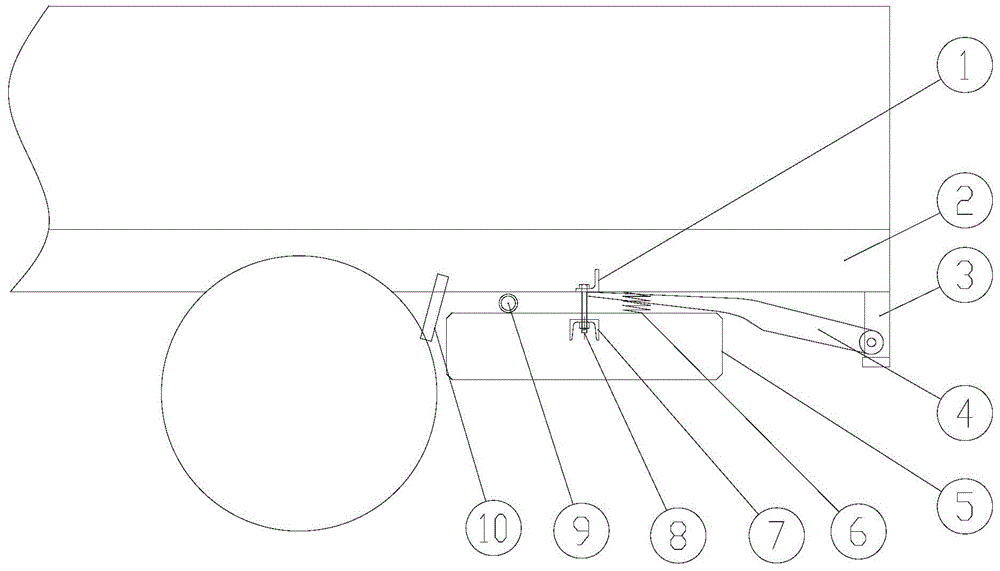

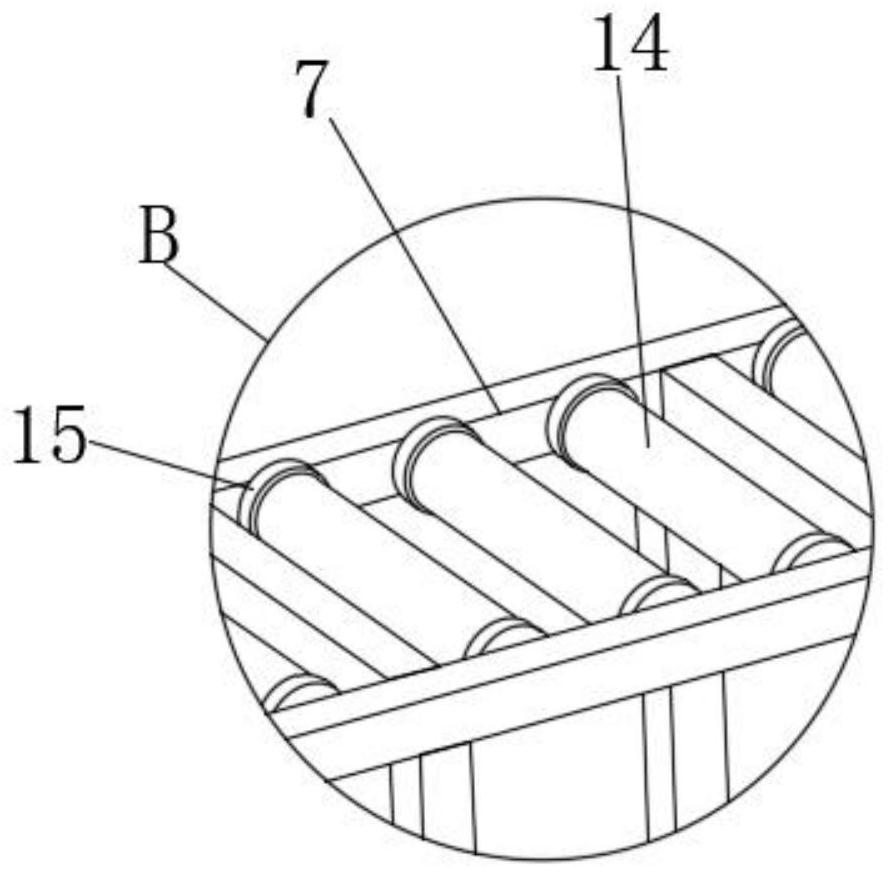

Punching sealing device for composite sealed bearing

InactiveCN103195825ATo achieve the purpose of sealingEasy to operateBearing componentsPunchingProduction automation

The invention discloses a punching sealing device for a composite sealed bearing, and belongs to the technical field of bearing manufacturing. The punching sealing device for the composite sealed bearing is characterized in that a punching device (3) comprises a conical punching head (6) with certain conical degree at the lower end; a sliding sleeve (7) is sleeved outside the sliding part at the upper end of the conical punching head (6); an elastic punching claw head (13) which can swell around when being extruded by the conical punching head (6) is sleeved outside the punching head part at the lower end of the conical punching head (6); the upper end of the elastic punching claw head (13) is connected with the lower end of the sliding sleeve (7); a plurality of claw heads capable of punching a steel-made dustproof cover (10) inside a bearing (9) to be punched are uniformly distributed at the circumference at the lower end of the elastic punching claw head (13); and a support sleeve (8) which can be supported at the outer circle of the bearing (9) to be assembled is sleeved at the outer circle of the elastic punching claw head (13). The punching sealing device for the composite sealed bearing can being used for punching and sealing the composite sealed bearing, is high in efficiency, has improvement on production automation, and is safe and reliable.

Owner:山东华泰轴承制造有限公司

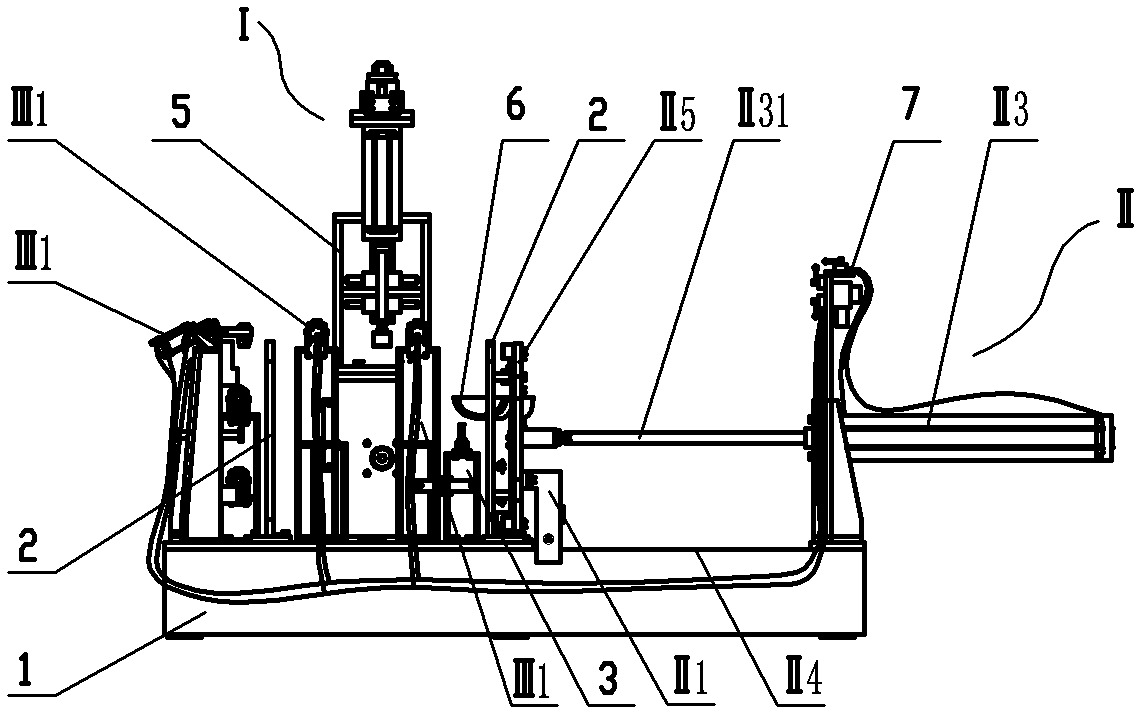

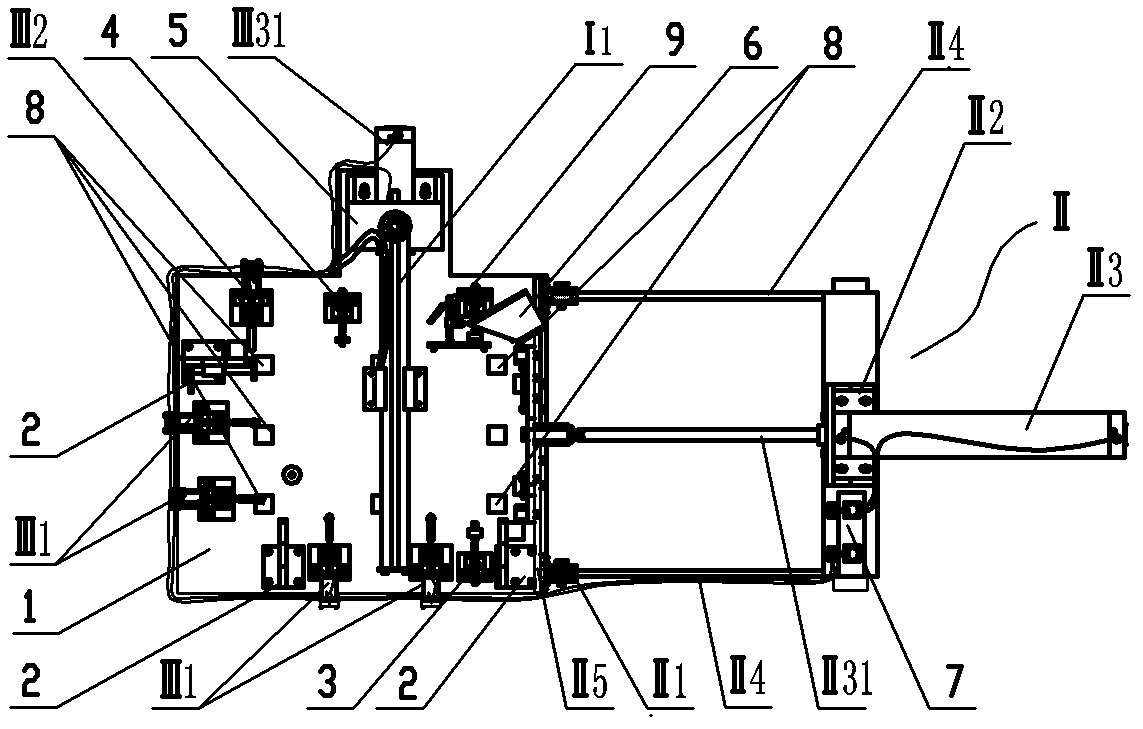

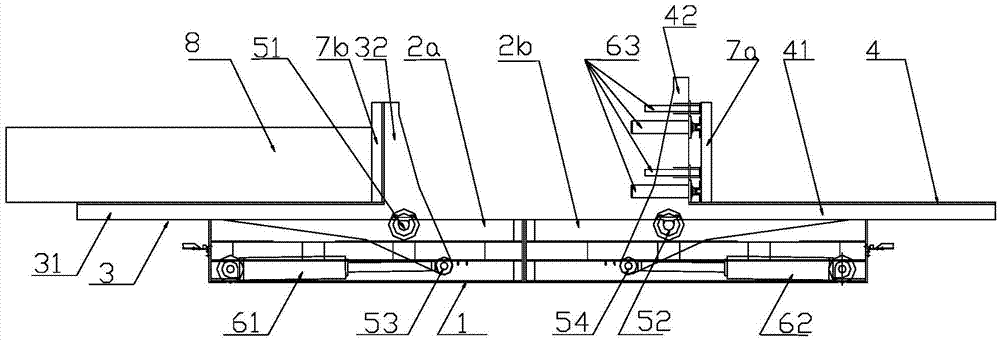

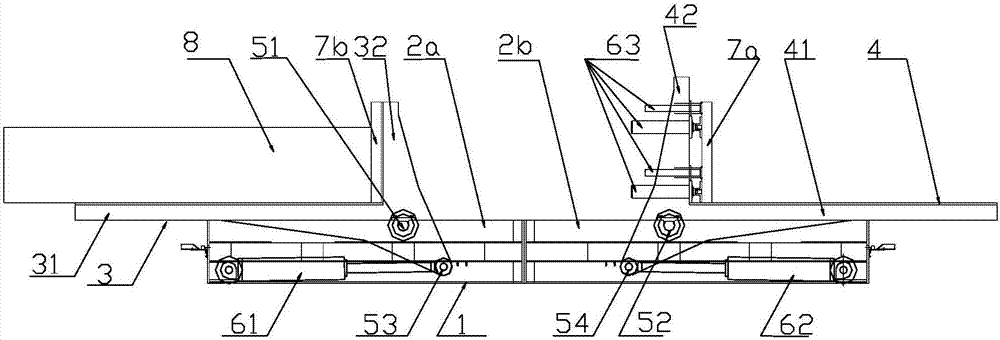

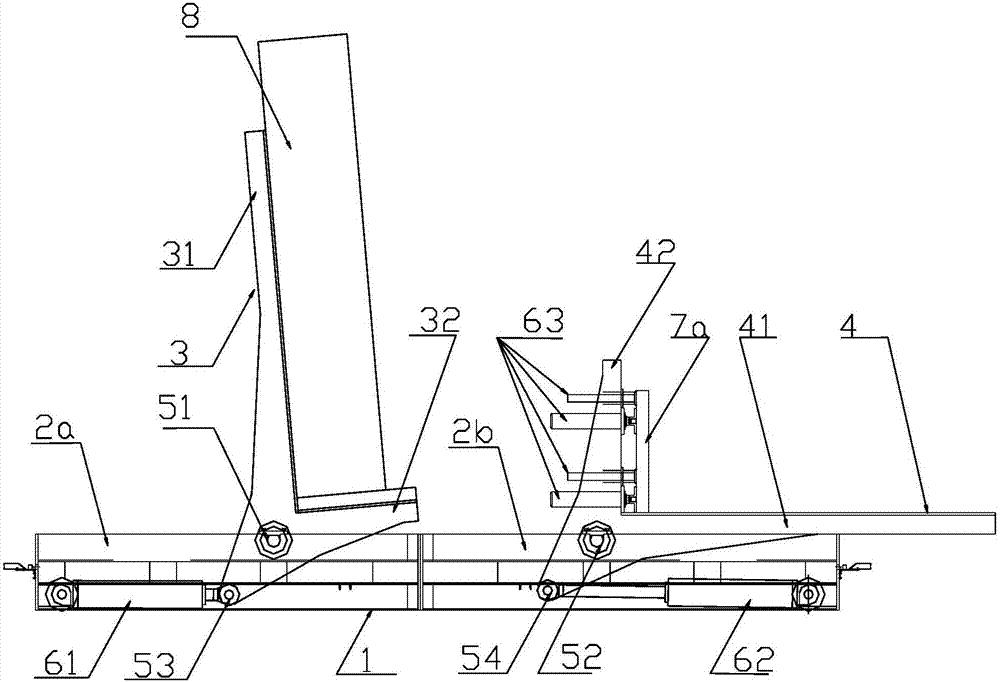

Skateboard pneumatic assembling device

InactiveCN102528367AGuarantee tooling accuracyImprove product qualityWelding/cutting auxillary devicesAuxillary welding devicesManufacturing cost reductionControl system

The invention relates to a skateboard pneumatic assembling device, which comprises a rack, a positioning seat arranged on a tooling platform of the rack, a skateboard upper pressing mechanism, a cover plate compression mechanism, a boarding compression mechanism and a control system, wherein a workpiece position to be assembled is arranged in the middle of the tooling platform, and the positioning seat, the skateboard upper pressing mechanism, the cover plate compression mechanism and the boarding compression mechanism are respectively positioned at the front side, the left side, the right side or the back side of the tooling platform according to the position of the positioned or compressed workpiece; and the control system controls compression cylinders of the compression mechanisms to be compressed or released, and thus the compression positioning of oil tank components needing to be assembled is realized. The skateboard pneumatic assembling device is flexible, is fast to compress, and is convenient to operate, the tooling of an oil tank is semi-automatic, the efficiency is improved, the labor intensity and the manufacturing cost are reduced, the stability of the tooling accuracy and the product quality is ensured; and the assembly gap of the oil tank is very small, so that welding slag are avoided being splashed into the oil tank, and thus the time of cleaning the inside of the oil tank in the following step can be shortened.

Owner:LIUZHOU BEIZHENGDA MACHINERY

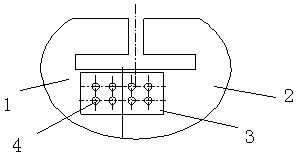

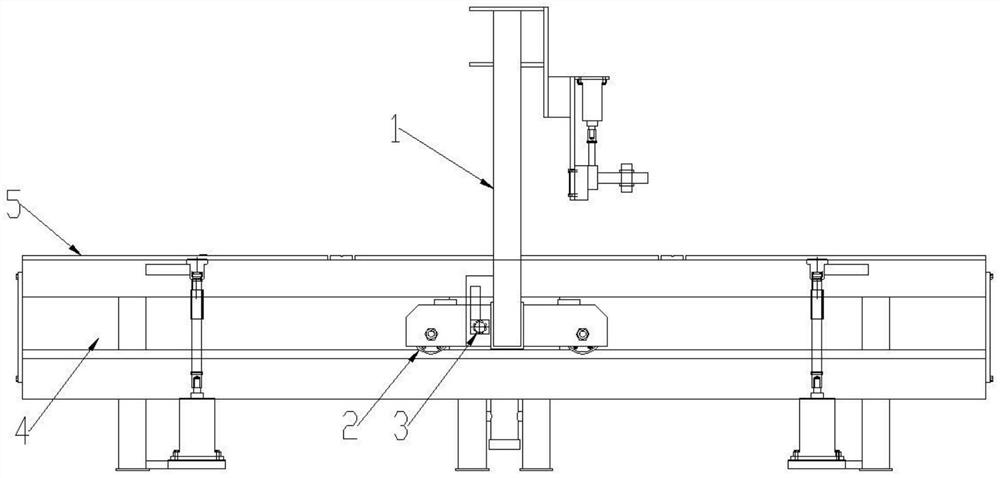

Automatic welding system for crane bogie frames

InactiveCN105414811AGuaranteed positioning accuracyReduce turnaround timeWelding/cutting auxillary devicesAuxillary welding devicesVehicle frameEngineering

The invention relates to an automatic welding system for crane bogie frames. The automatic welding system for crane bogie frames comprises a flexible tool clamp and a robot welding system. The flexible tool clamp comprises a base. A bottom pressing block A and a bottom pressing block B are arranged at the upper end of the base. A stand column A is arranged in the middle of the right side of the base, a pressing bolt A is arranged in the middle of the stand column A, a hydraulic rod A is arranged in the center of the top of the stand column A, and a connection block A is arranged on the top of the hydraulic rod A. A fixing block A is arranged in the connection block A, and an upper pressing block A is arranged on the left side of the fixing block A. A stand column B is arranged in the middle of the left side of the base, a pressing bolt B is arranged in the middle of the stand column B, a hydraulic rod B is arranged in the center of the top of the stand column B, and a connection block B is arranged on the top of the hydraulic rod B. The automatic welding system for crane bogie frames has the beneficial effects of being automatic, stable in welding quality and high in welding efficiency.

Owner:HENAN SINOKO CRANES

Water meter detection support with adjusting mechanism

PendingCN112179456AQuick flipImprove continuityTesting/calibration for volume flowWater conservationSlide plateControl theory

Owner:湖南常德牌水表制造有限公司

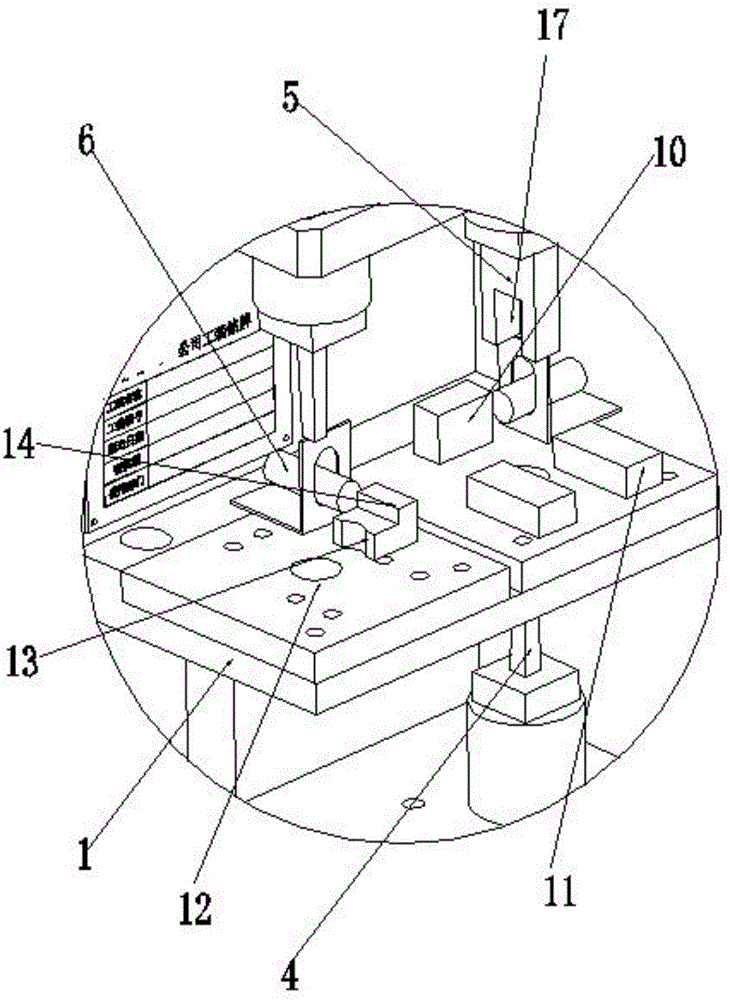

Induction type non-flip stop spot dotting tool and using method thereof

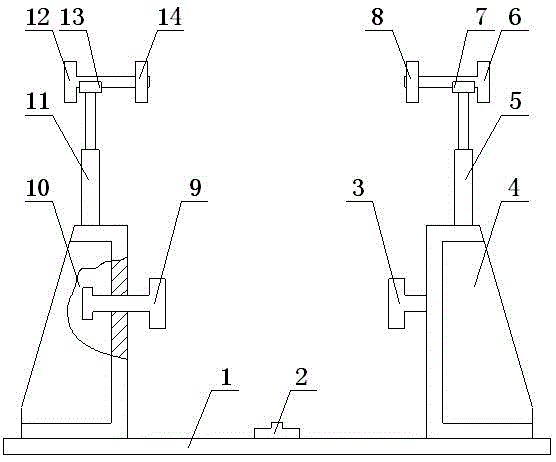

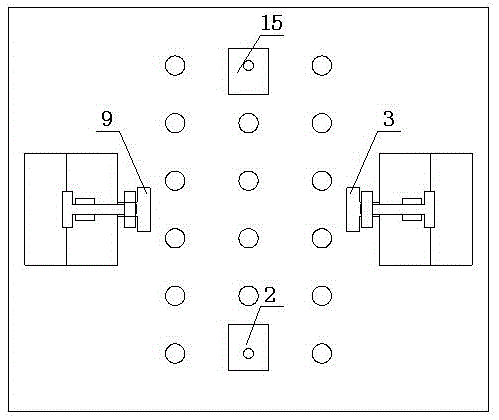

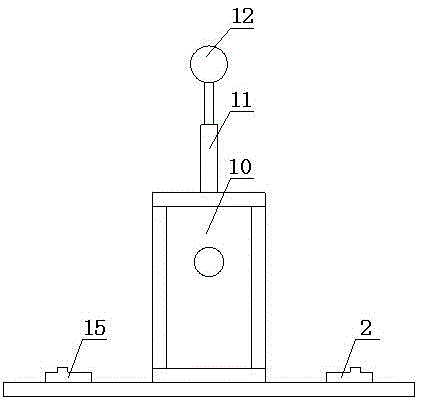

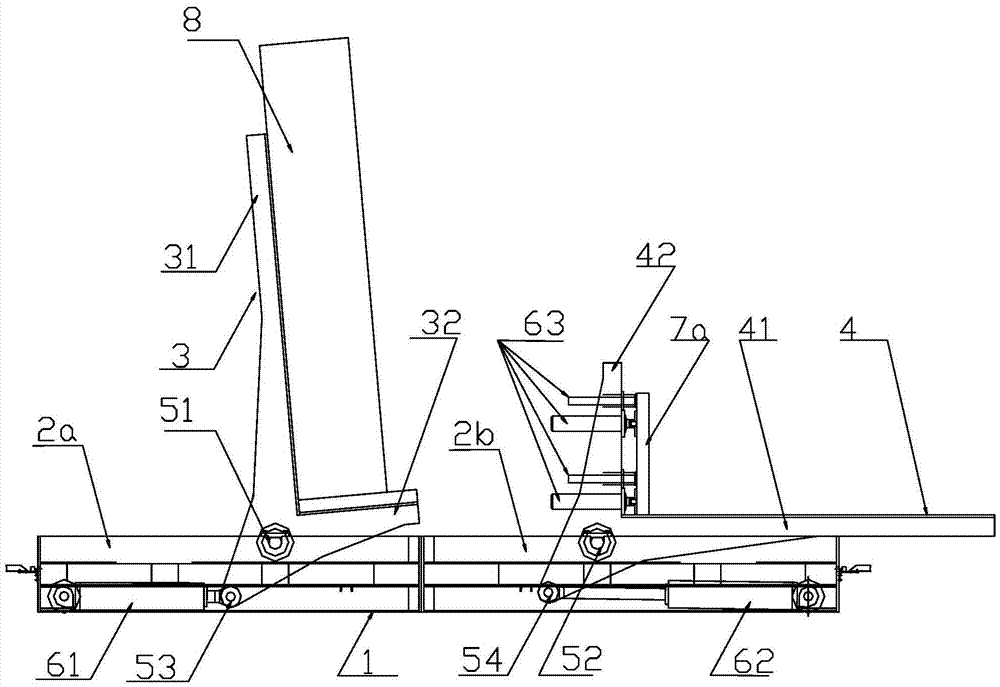

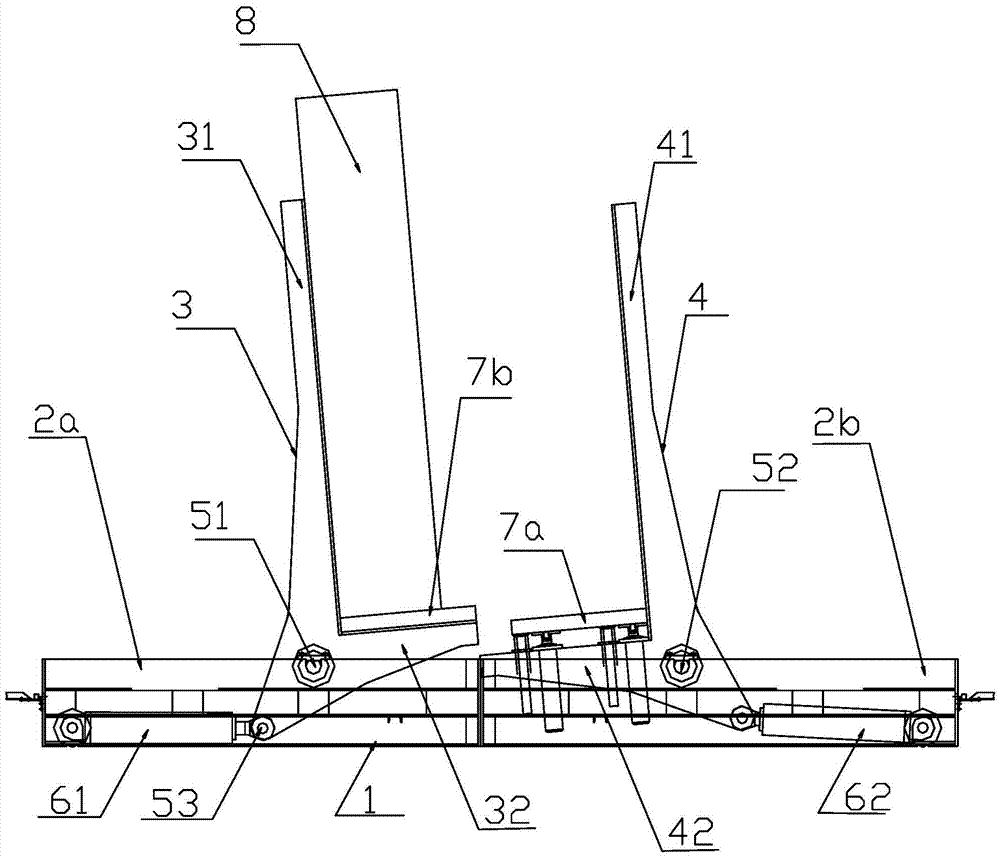

ActiveCN106334741AReduced risk of collisionSave time flippingMetal-working feeding devicesVehicle componentsPerpendicular directionRejection rate

The invention relates to the field of production equipment of crossing glass lifters, in particular to an induction type non-flip stop spot dotting tool and a using method thereof. The stop spot dotting tool comprises a workbench. A short guide rail stop block assembly for limiting a short guide rail and a long guide rail stop block assembly for limiting a long guide rail are arranged on the workbench. A power air cylinder for dotting stop spots on the short guide rail is arranged on one side of the portion, where the short guide rail is arranged, of the workbench in the perpendicular direction. A power air cylinder for dotting stop spots on the long guide rail is arranged on one side of the portion, where the long guide rail is arranged, of the workbench in the perpendicular direction. The long guide rail power air cylinder and the short guide rail power air cylinder are located on the two sides of the workbench correspondingly. The long guide rail is provided with a pressing sliding column for tightly pressing the long guide rail on the same side as the short guide rail power air cylinder. The flip time in work is saved, the risk that a motor is bumped due to flip is reduced, the working efficiency is improved, and the rejection rate is lowered.

Owner:WUHU MOTIONTEC AUTOMOTIVE

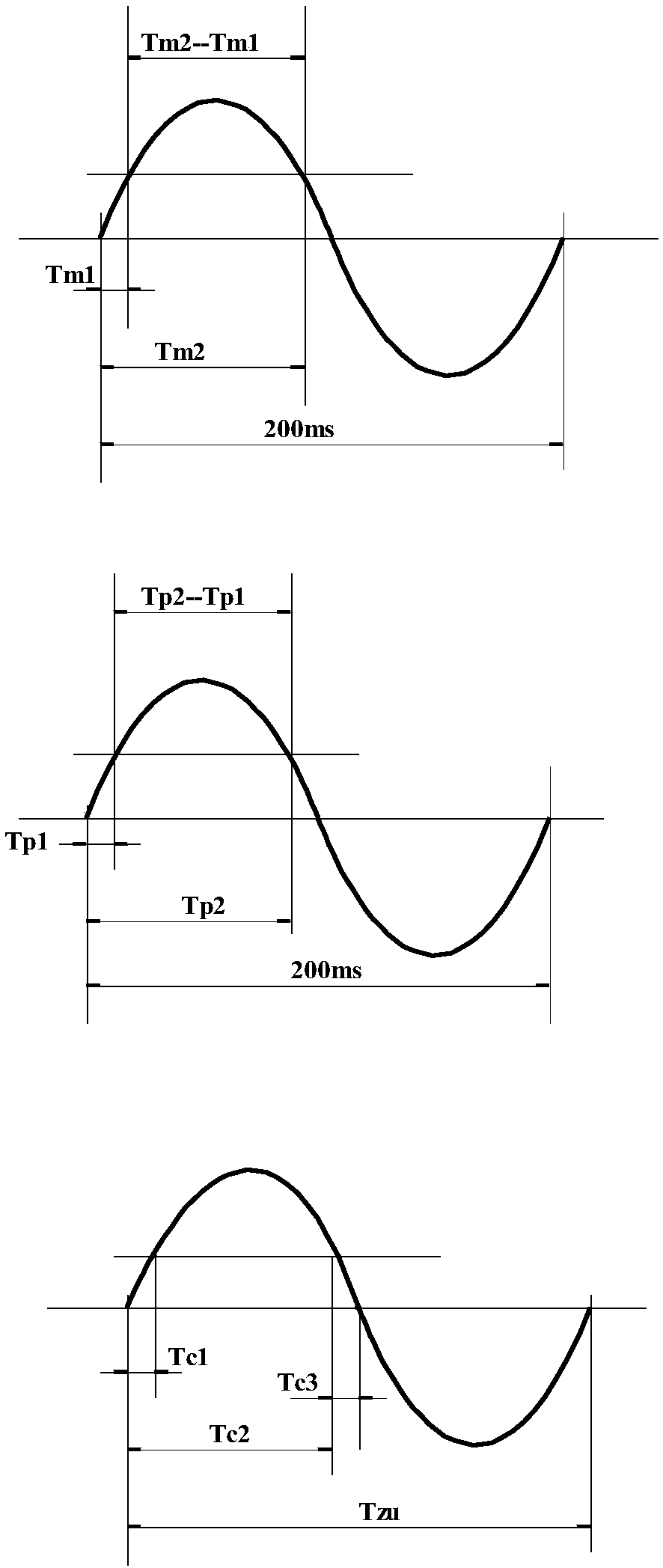

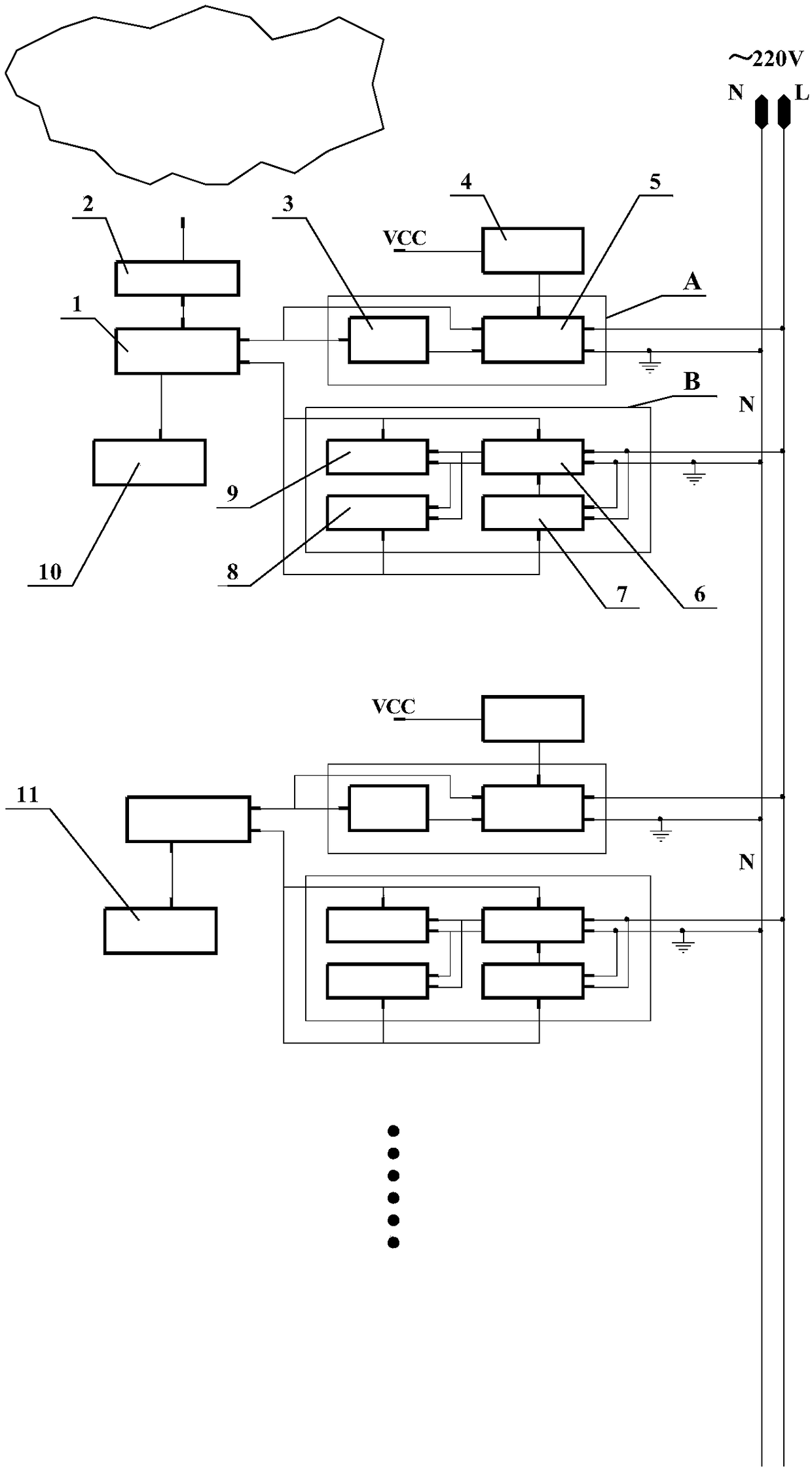

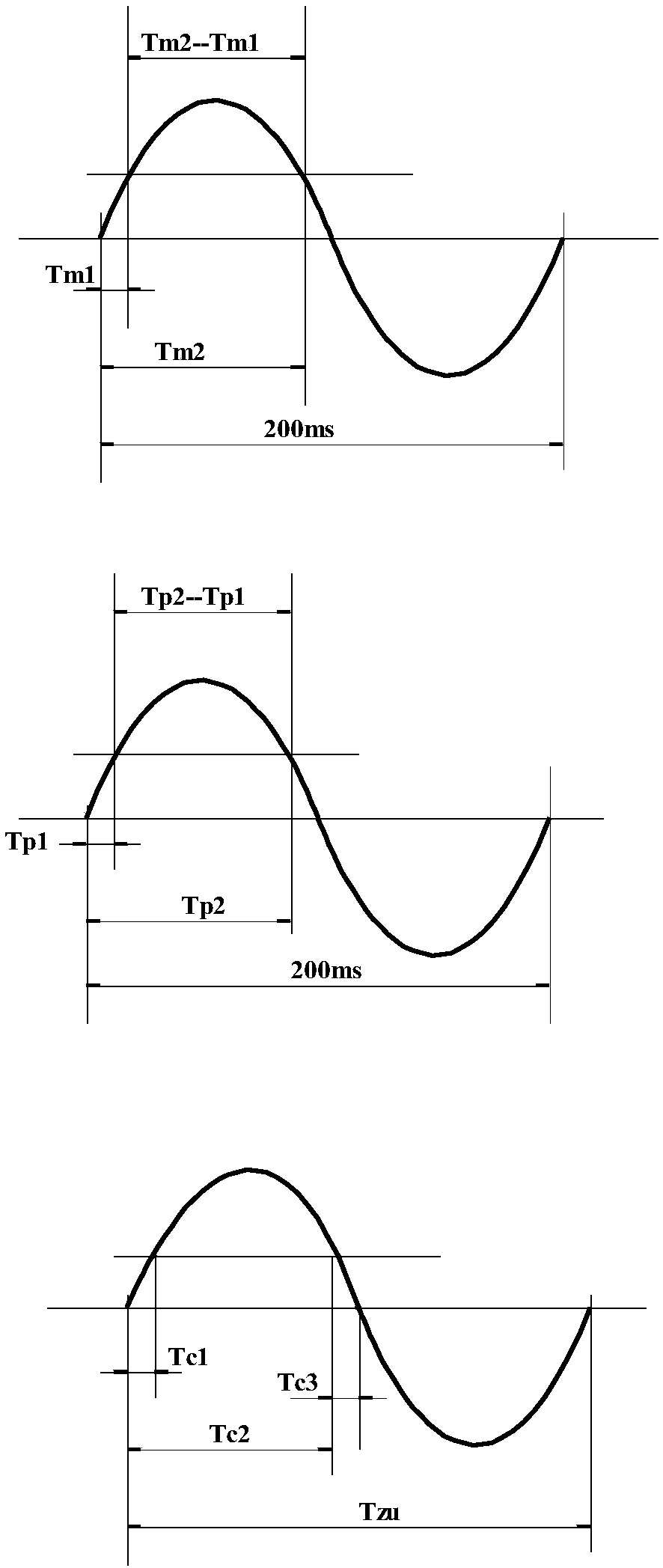

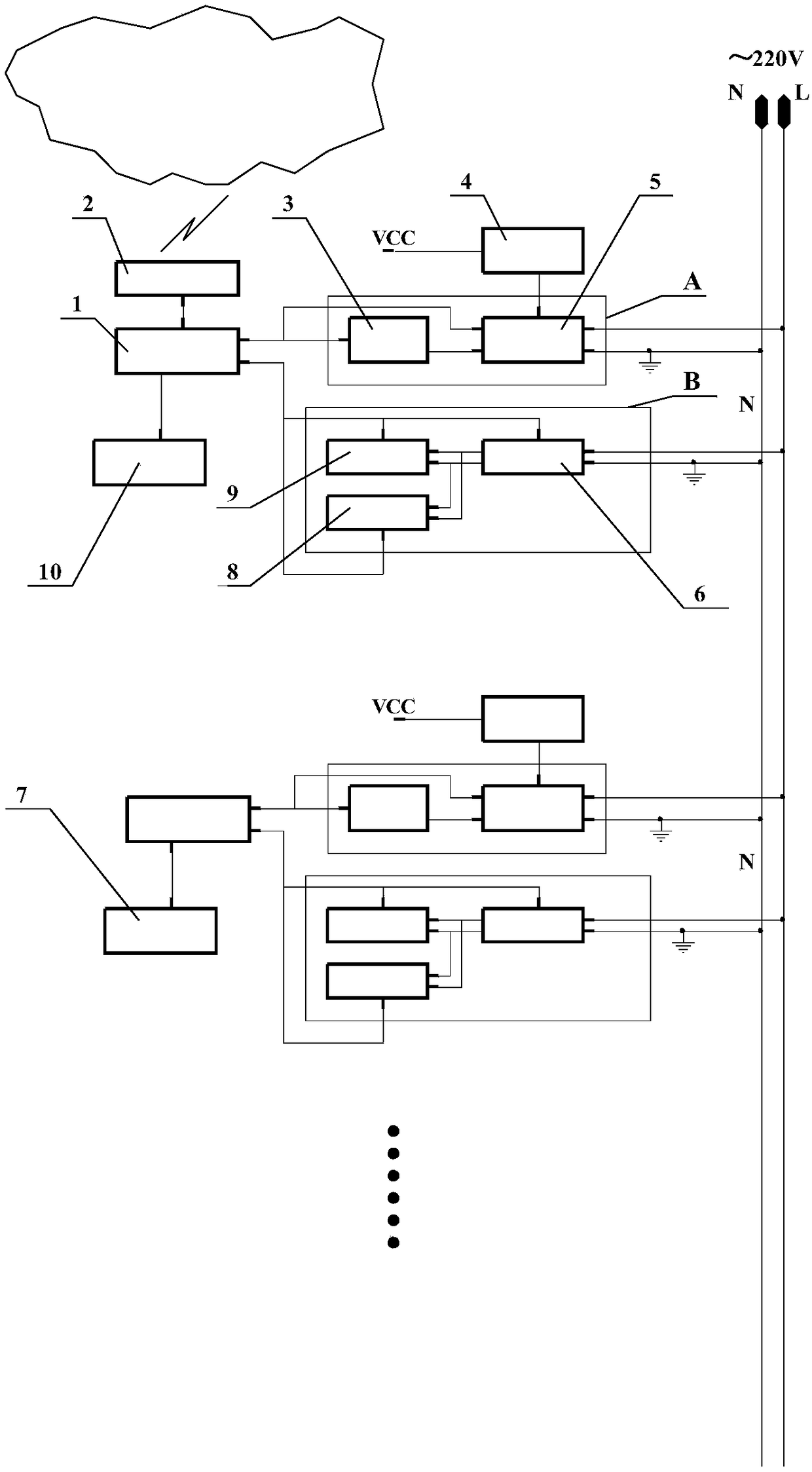

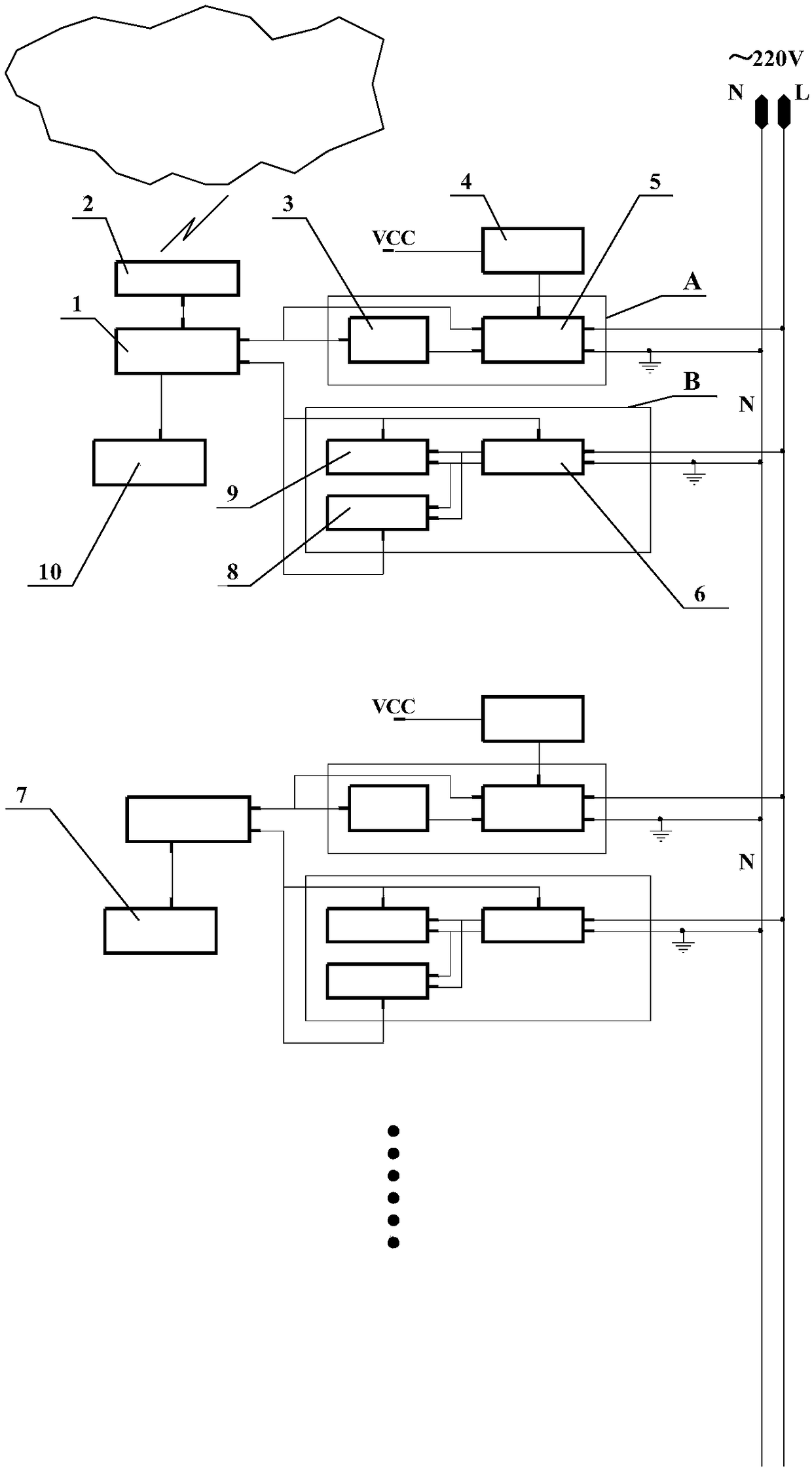

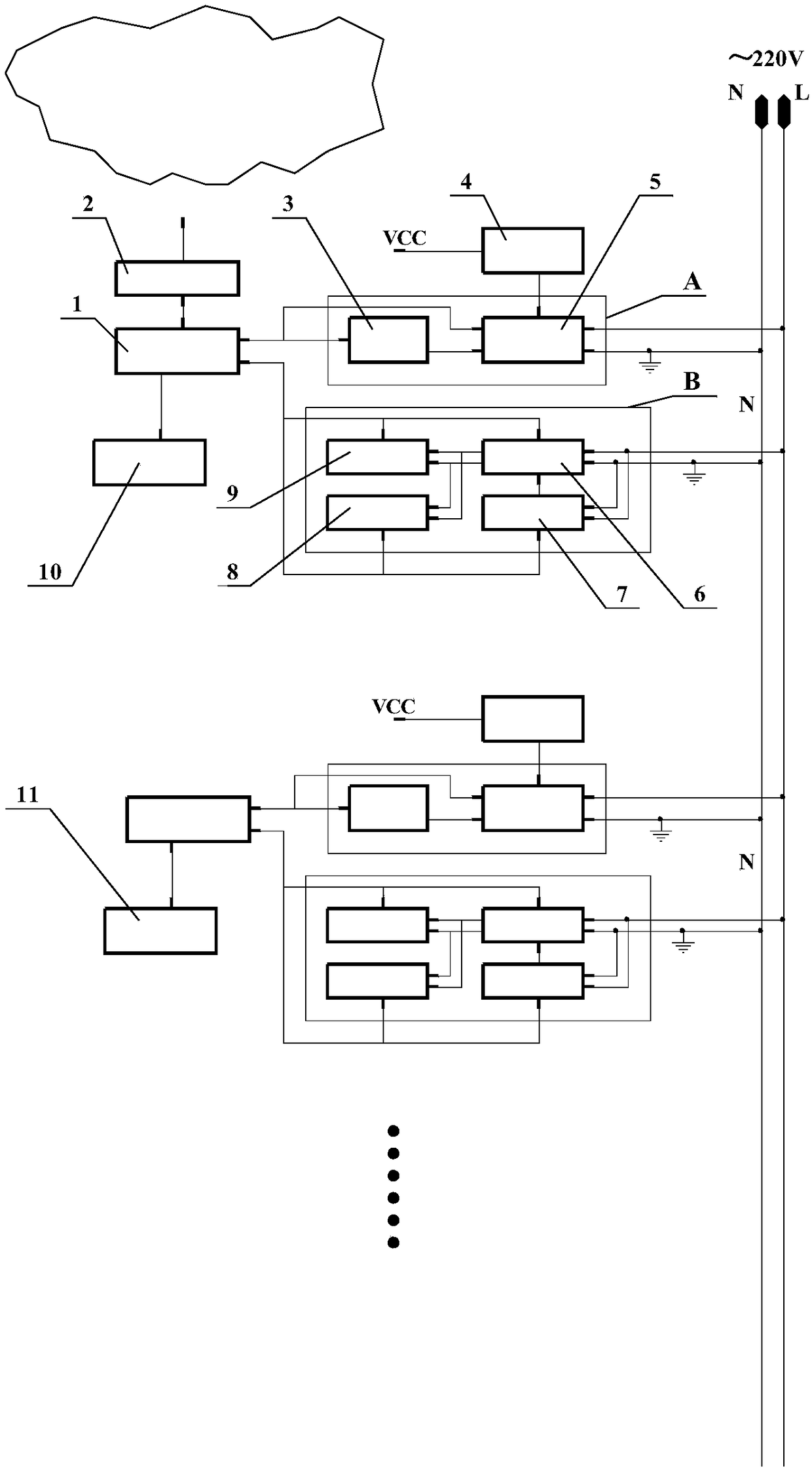

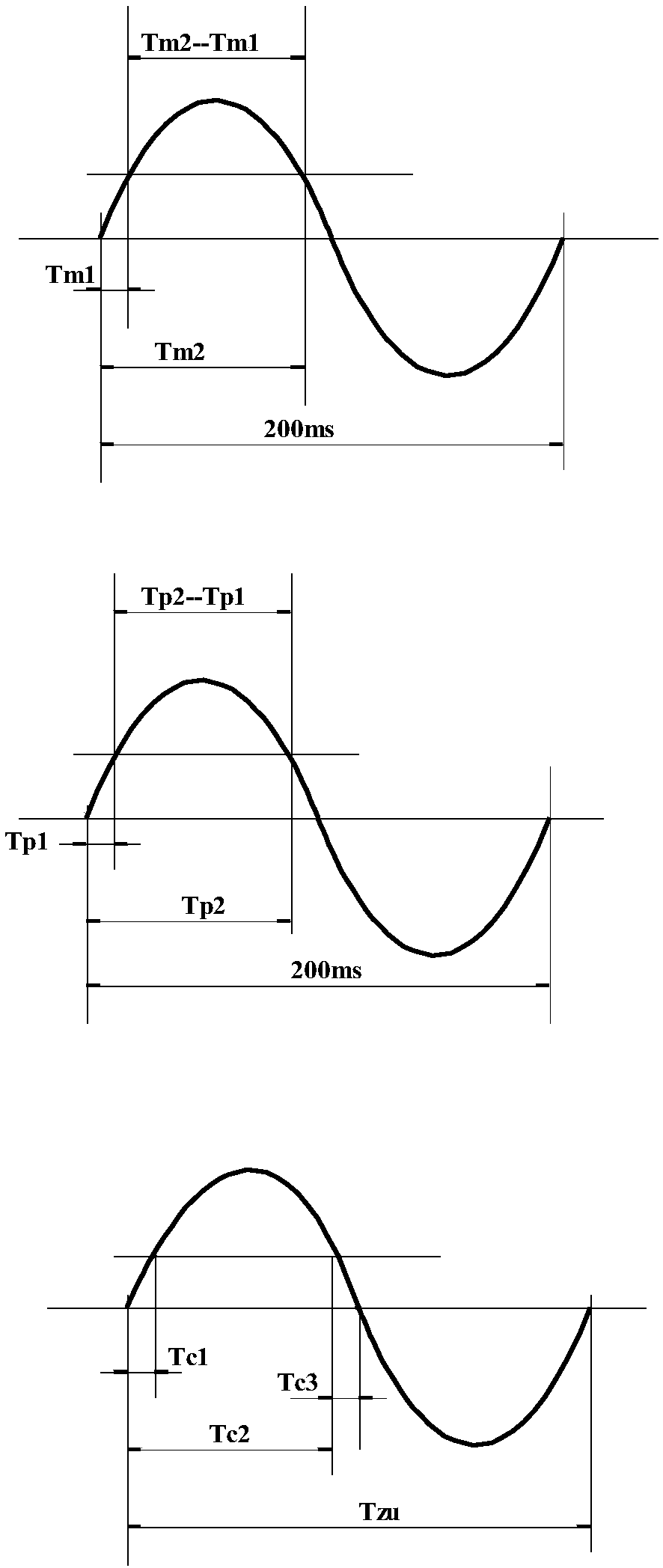

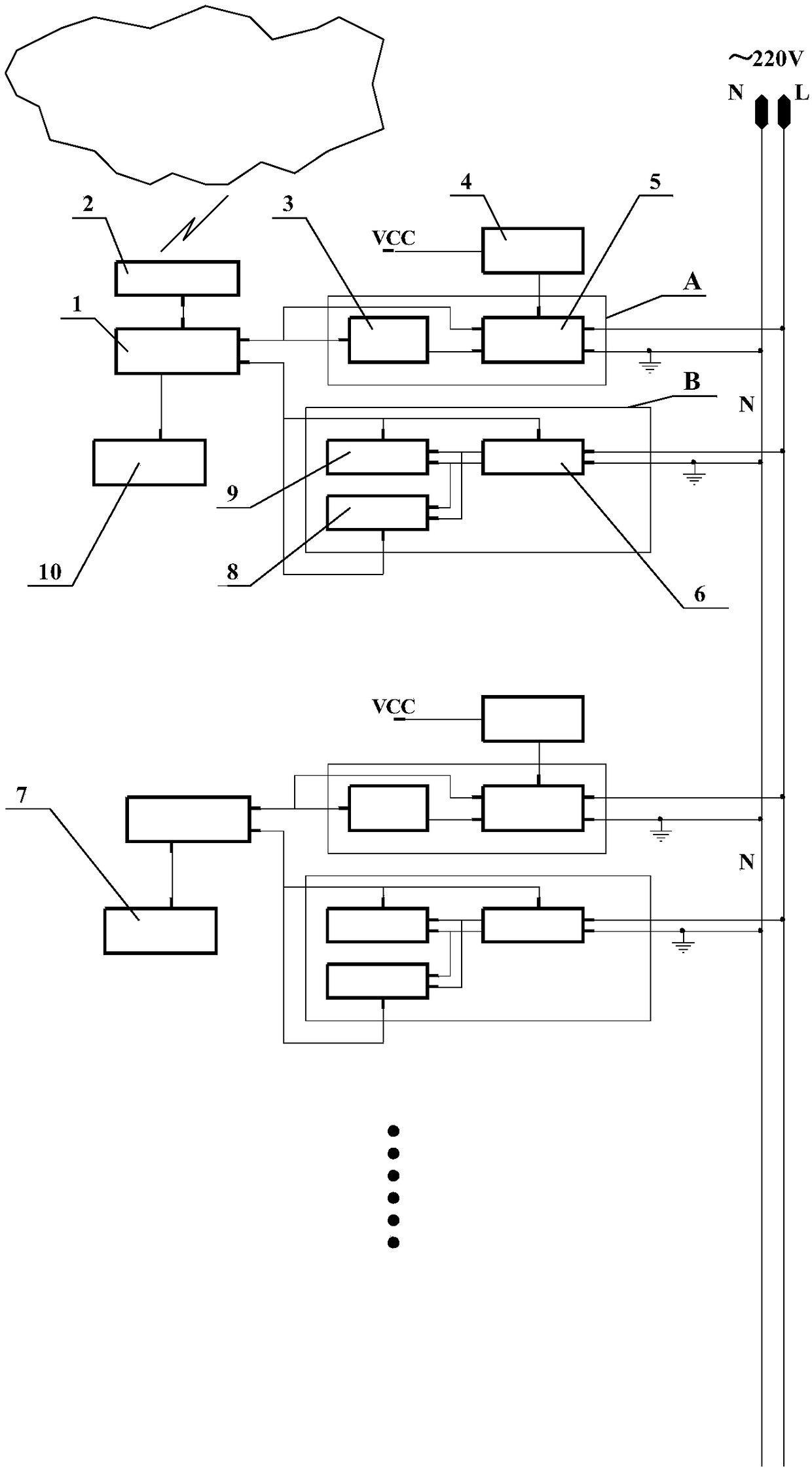

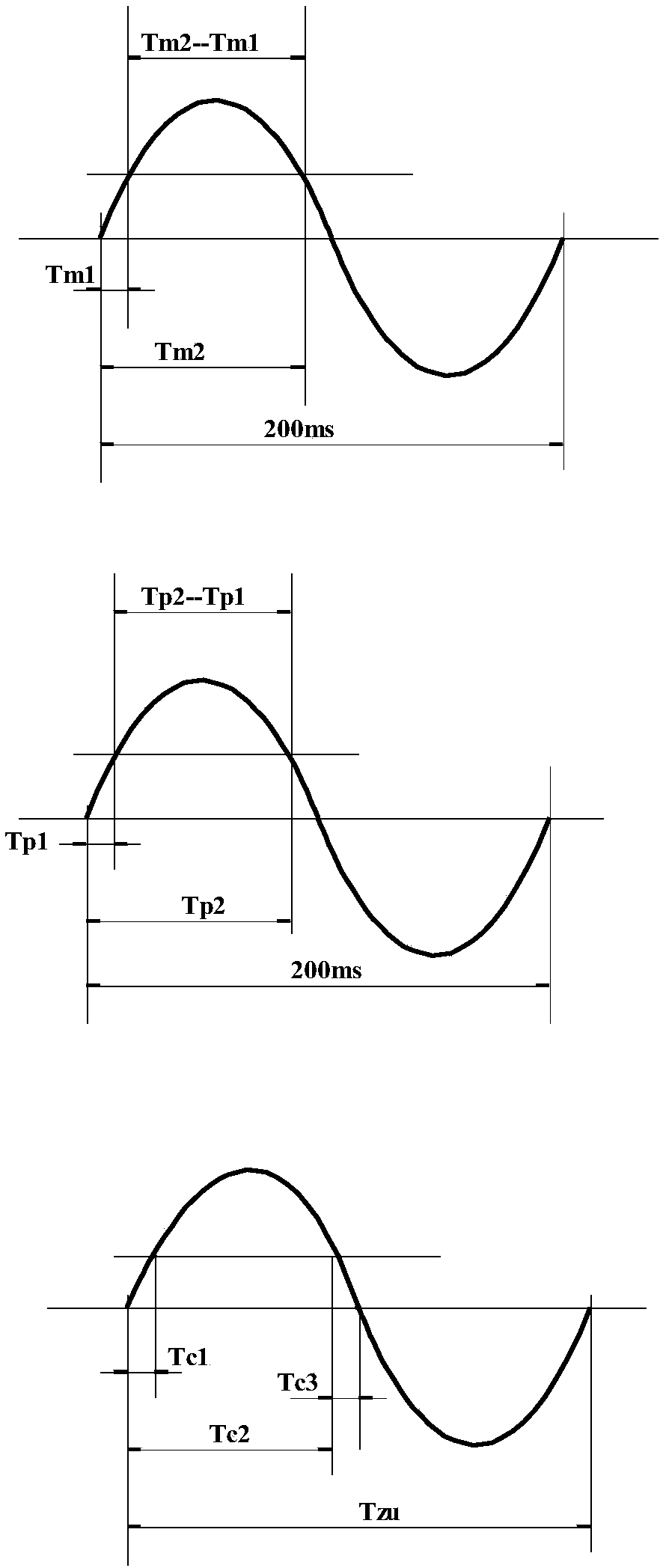

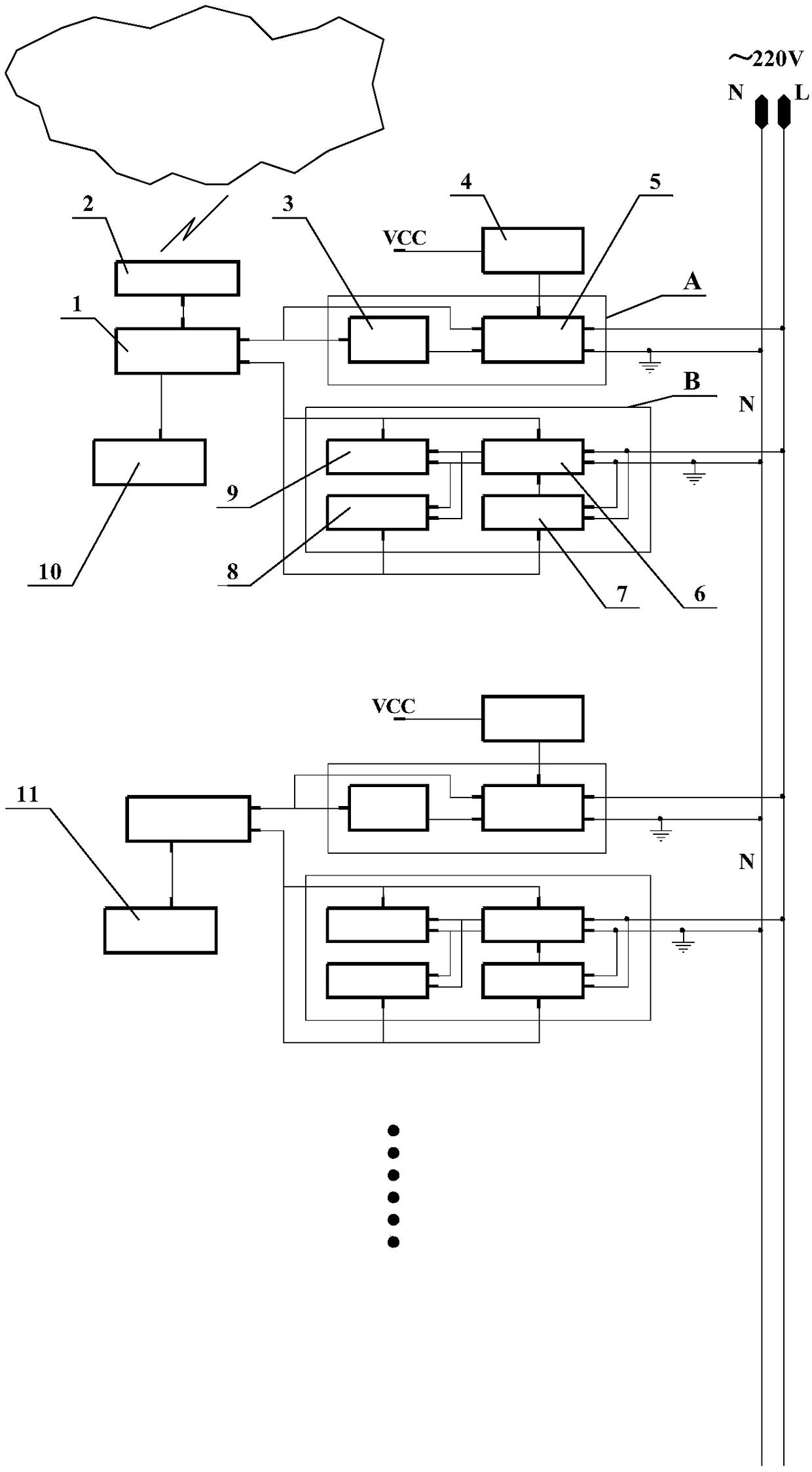

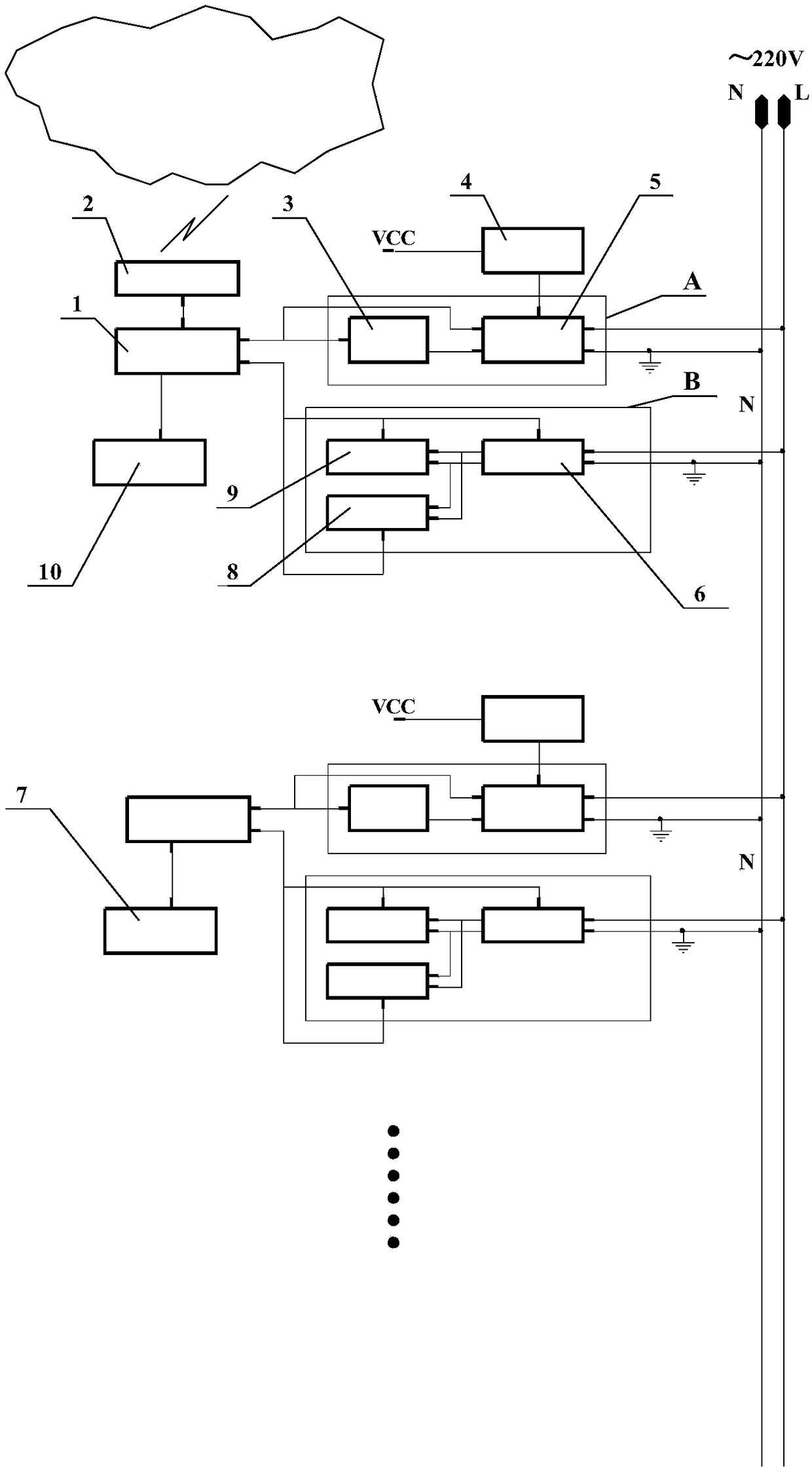

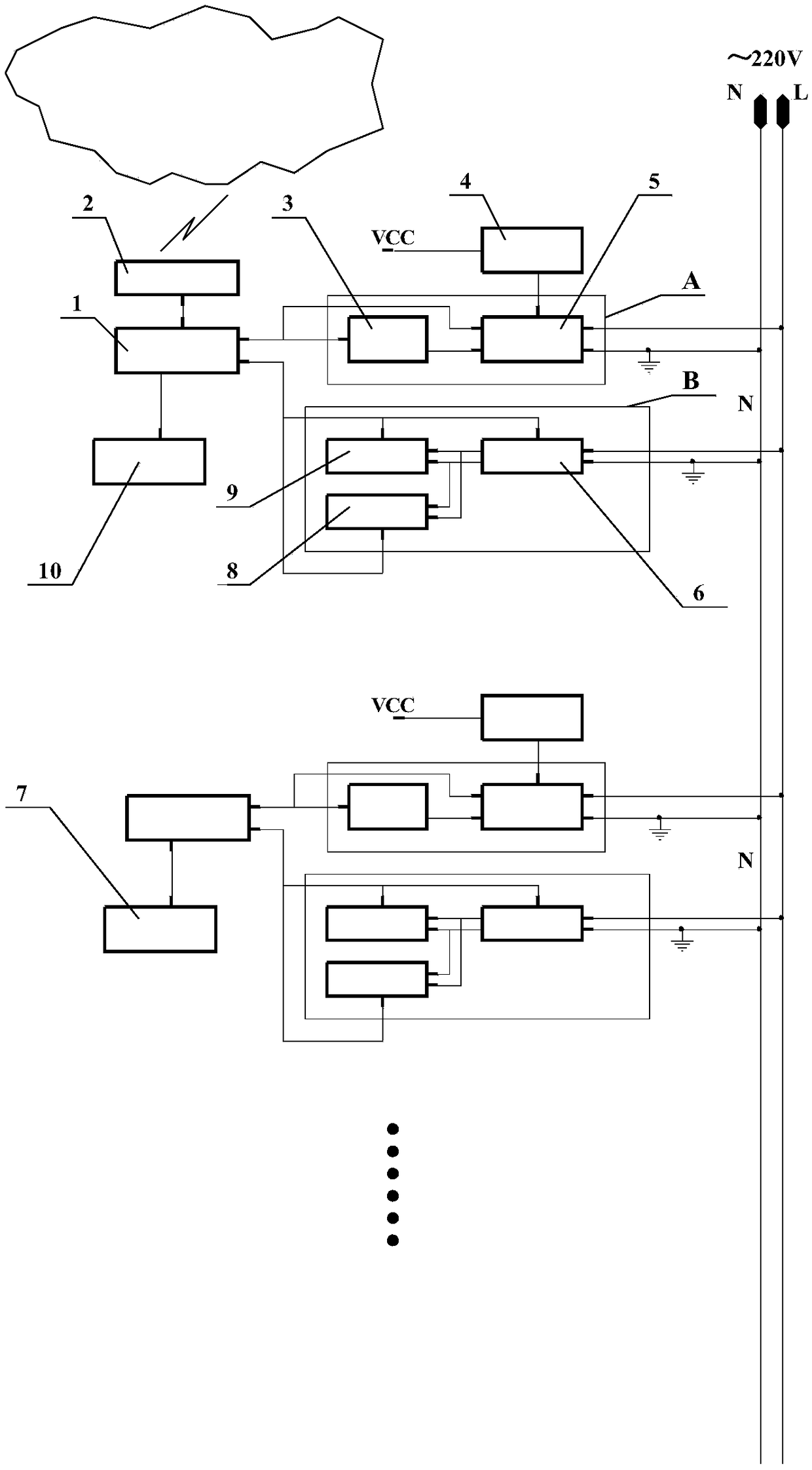

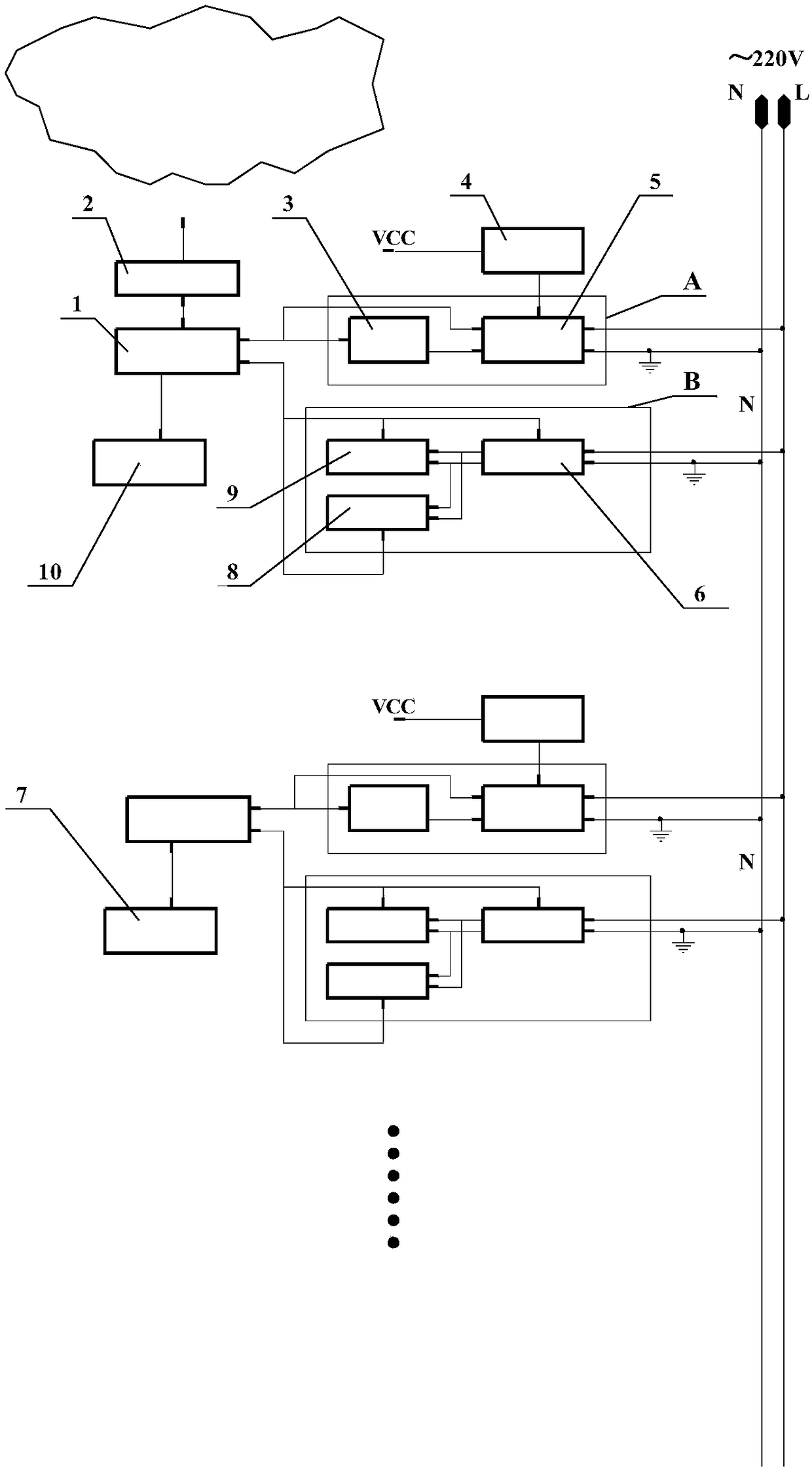

Analog quantity remote collecting and alarming system

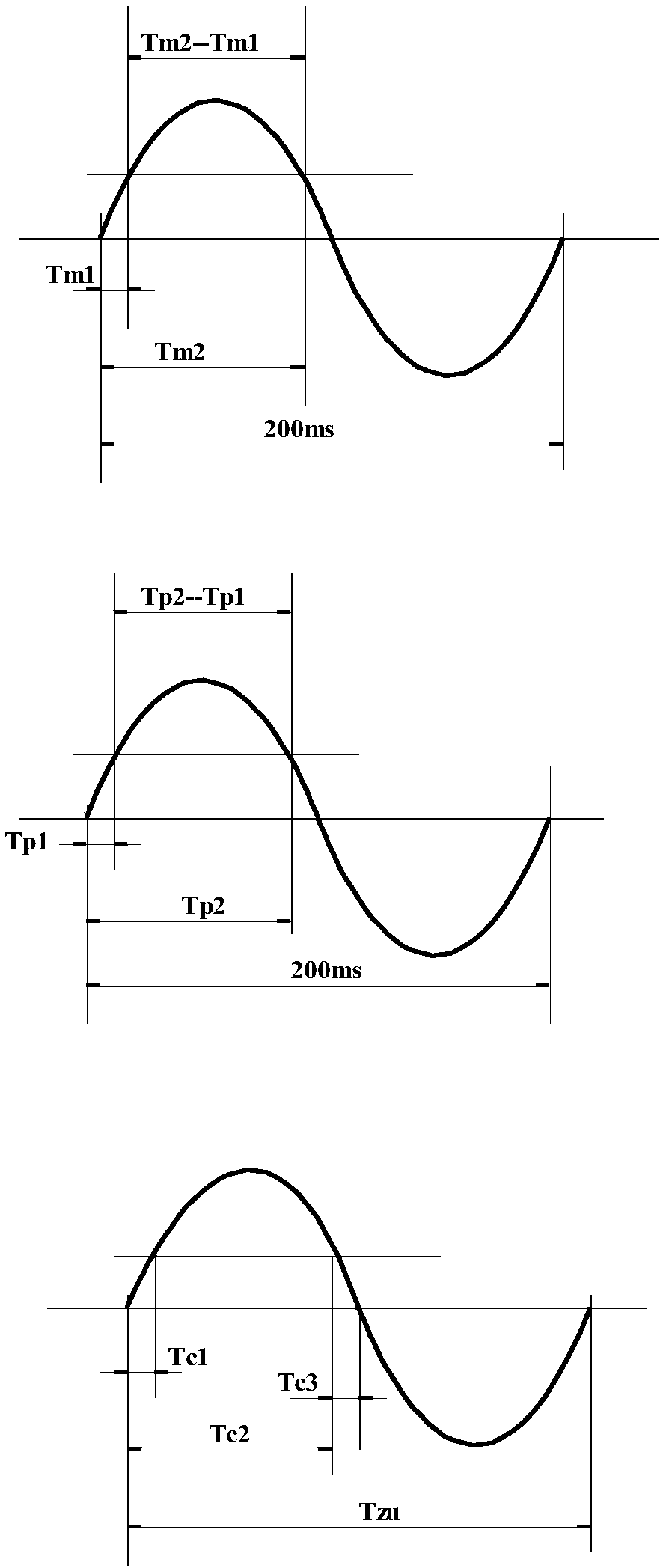

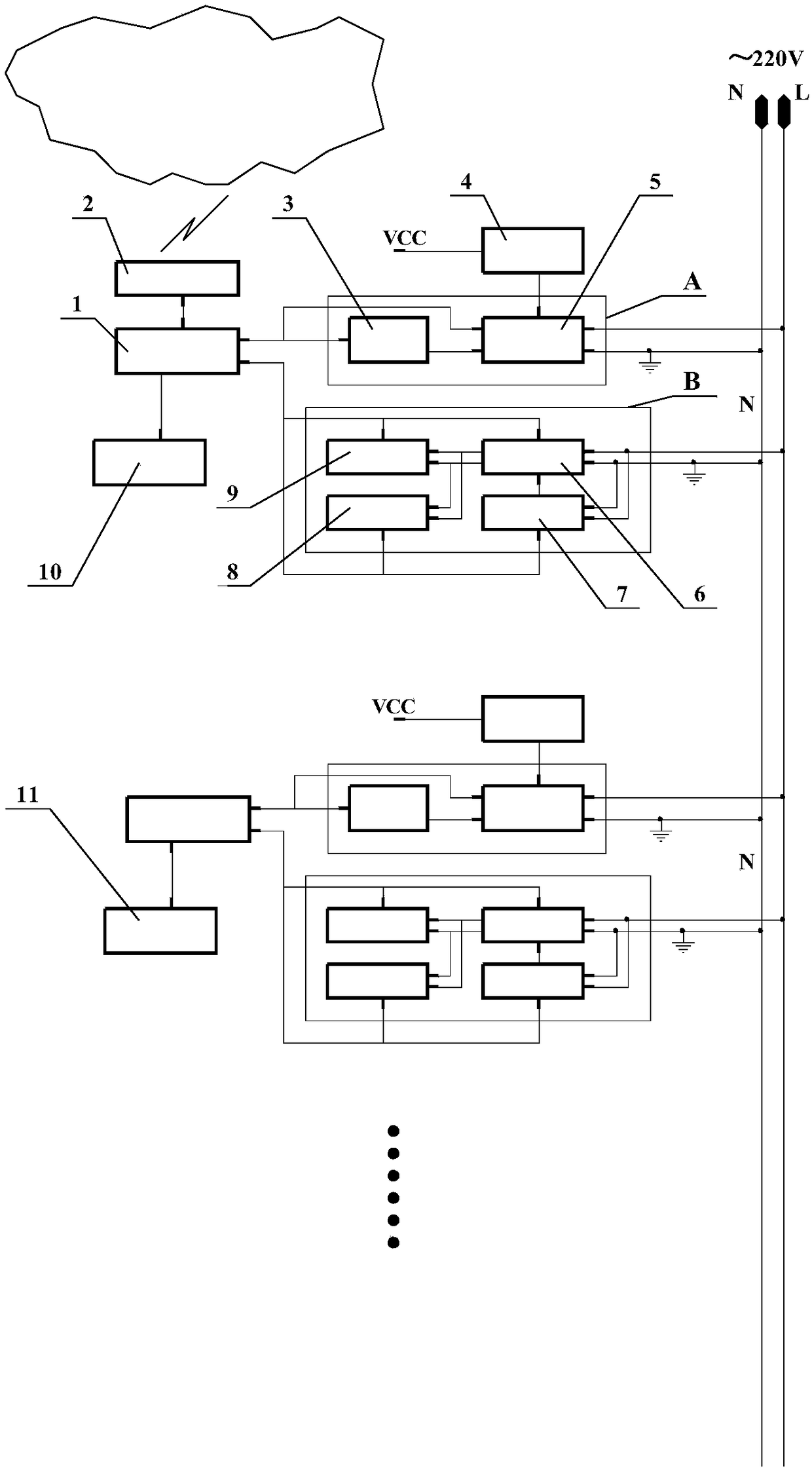

InactiveCN108919718ALower impedanceIncreased flipping timeProgramme controlElectric signal transmission systemsRemote systemMeasuring instrument

The invention relates to an analog quantity remote collecting and alarming system for collecting and remote transmission of various physical quantities. Measuring instruments upload measured data to centralized controllers in a power line communication mode, each measuring area is provided with one centralized controller. The measuring instruments in the measuring areas conduct synchronous sampling preserving through an ADC, the centralized controllers are connected into the internet through a network interface module, thus the centralized controllers are networked with a remote computer management system of a master station, and conduct alarming to the remote system when the measured data exceed the limit.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

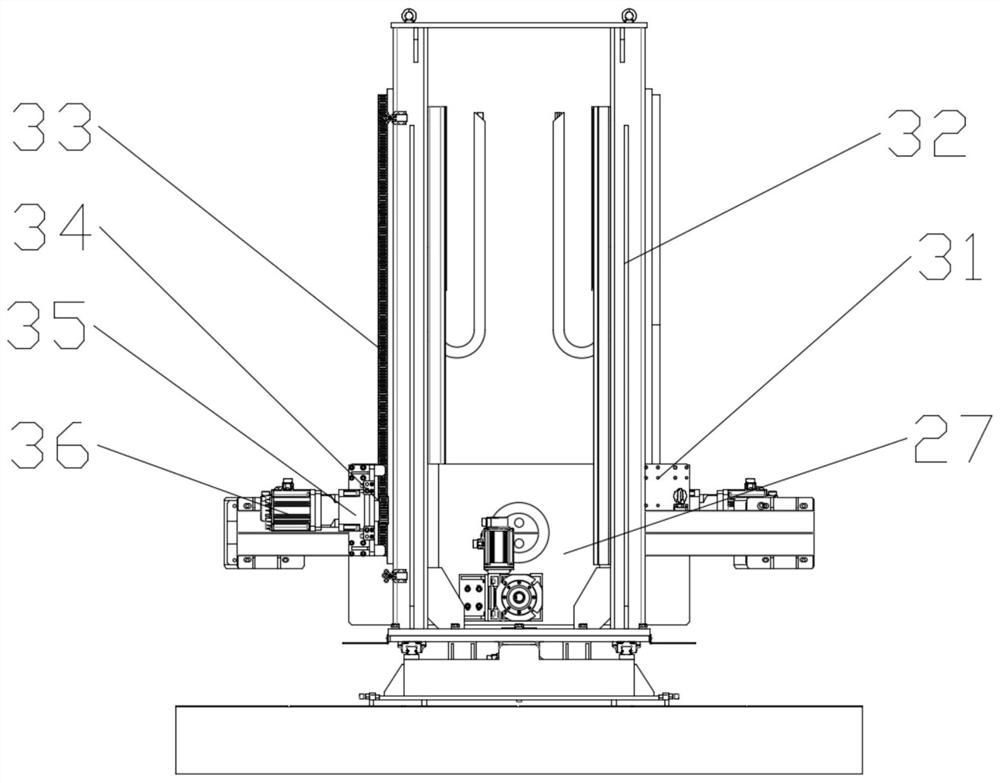

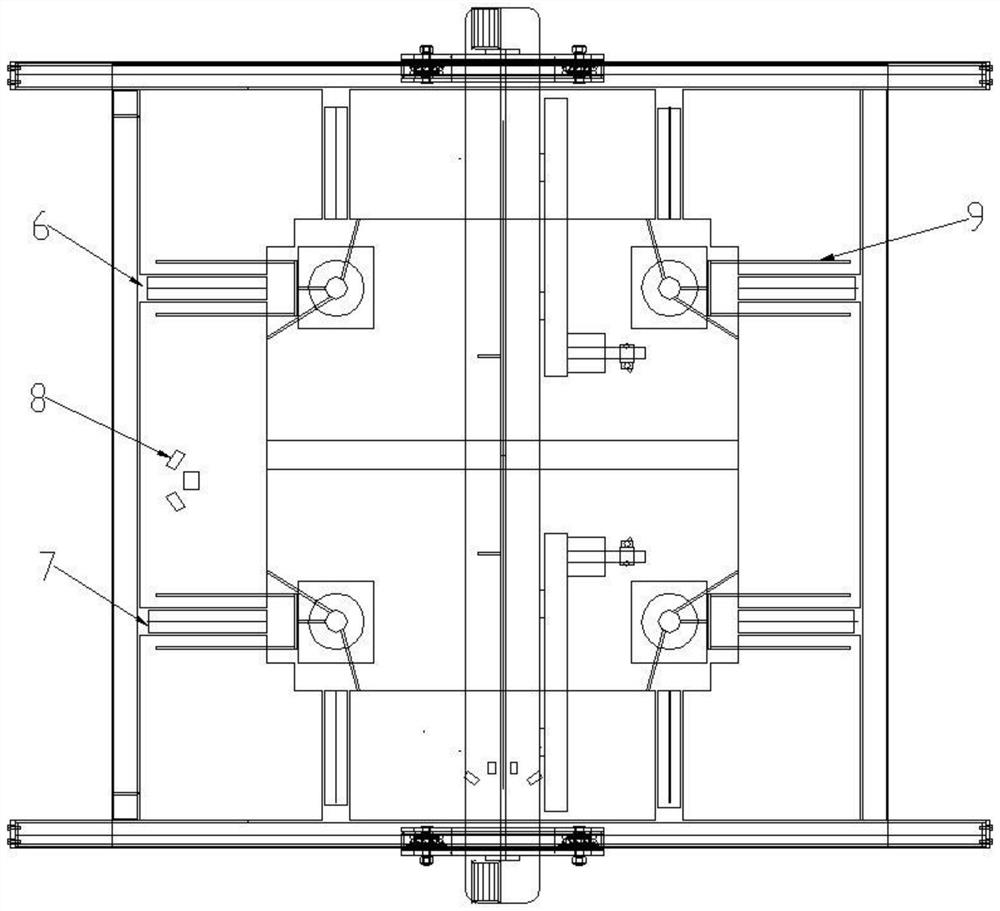

Workpiece turnover device

InactiveCN105439057AReduce vibrationPrecise positioningLifting devicesHoisting equipmentsFixed frameEngineering

The invention discloses a workpiece turnover device, and relates to mechanical equipment, in particular to the workpiece turnover device for overturning assembled T-shaped or H-shaped steel and several special cylinders and pipes with greater outer diameters and weights and shorter lengths by 0-180 degrees and applied to overturning movement of movable workpieces, in particular applied to such stations as welding turnover, correcting turnover, assembling turnover, flaw detection and manual welding. The workpiece turnover device comprises a base and a frame; the frame includes a fixed frame and a movable frame; the fixed frame is fixed on the base; the movable frame is movably connected with the base through a guide rail; an L-shaped first rotating arm is rotationally connected with the fixed frame through a rotating shaft A; and an L-shaped second rotating arm is rotationally connected with the movable frame through a rotating shaft B, and can perform a translational motion along with the movable frame. The workpiece turnover device has the advantages of safety, light turnover, difficult workpiece damage and deformation, low labor intensity of workers and high production efficiency.

Owner:WUXI LUSHENG MACHINERY EQUIP

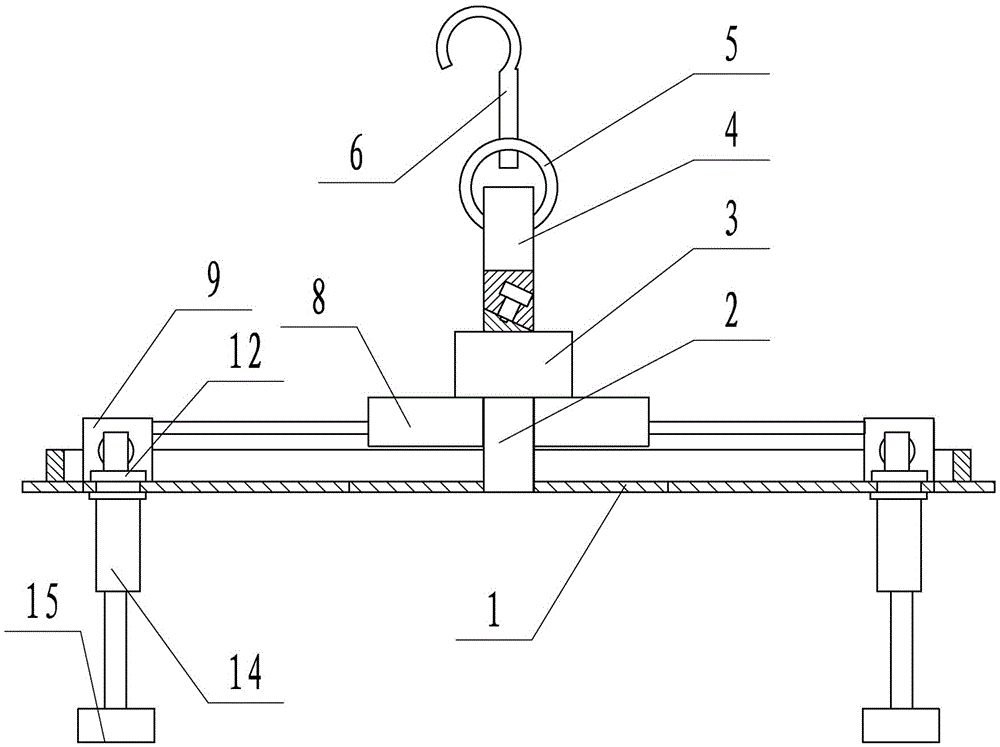

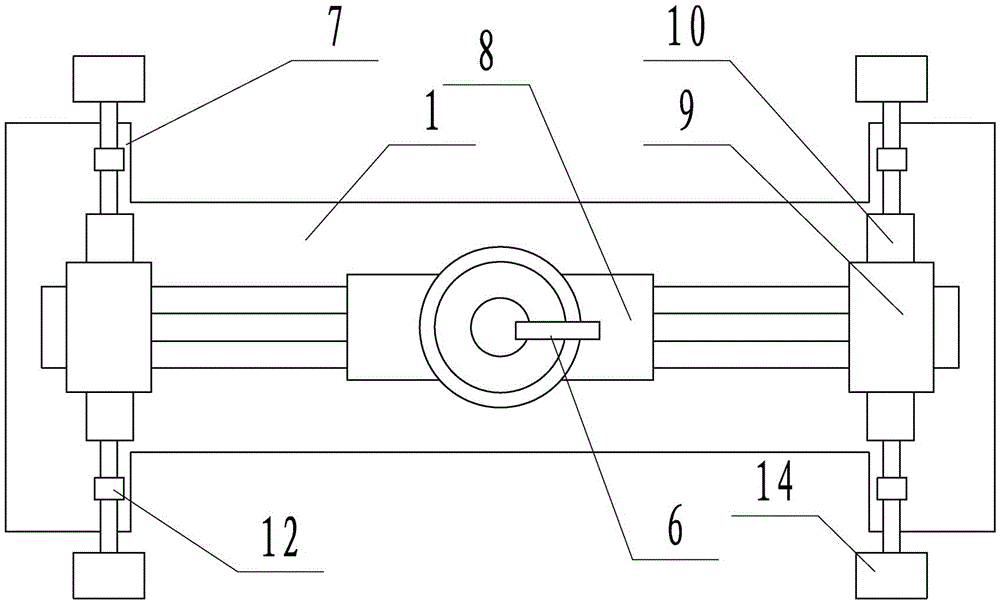

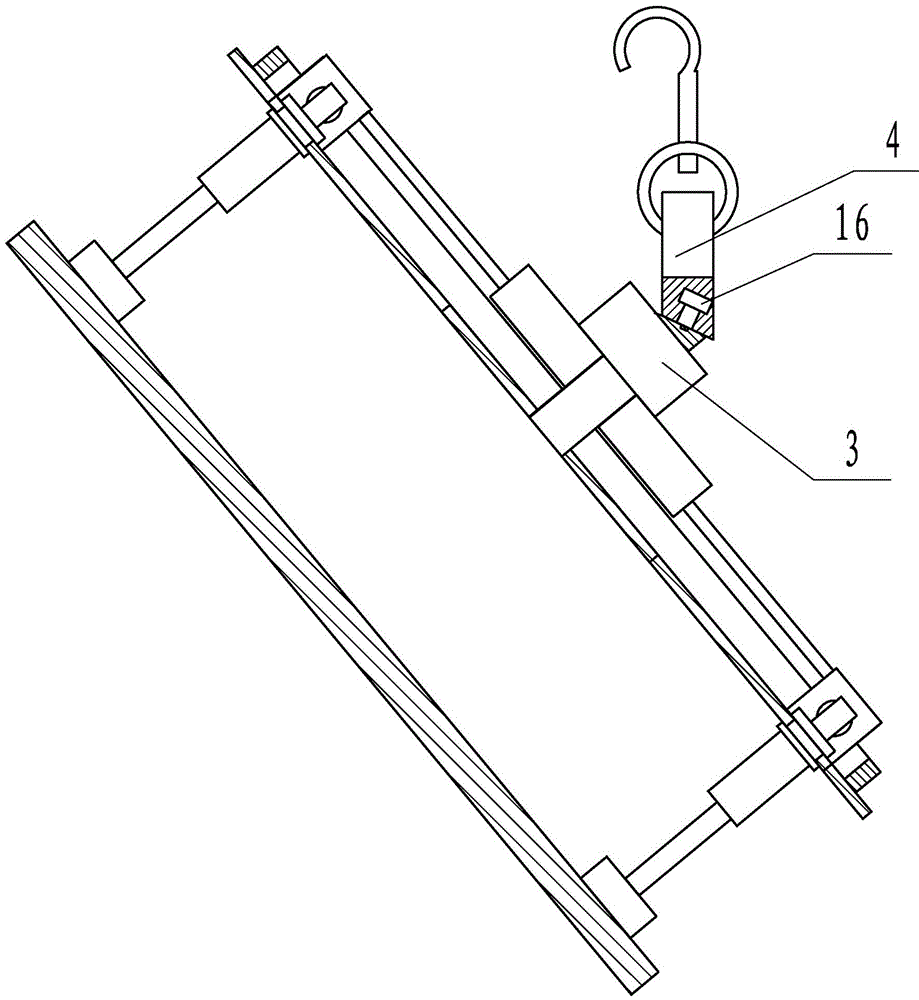

Device for accurately hoisting roof beam

The invention relates to a device for accurately hoisting a roof beam. The device comprises a guiding frame arranged horizontally, a center base vertically arranged in the center of the guiding frame, an upper connecting seat arranged at the upper end of the center base, an extension shaft arranged on the upper connecting seat, a hoisting ring arranged at the upper end of the extension shaft, a hanger arranged at the upper end of the hoisting ring, two first driving cylinders symmetrically arranged on the upper surface of the guiding frame in the length direction of the guiding frame, and lateral guiding blocks arranged at the end parts of the piston rods of the first driving cylinders, and the device provided by the invention has a reasonable structure, is advanced in design, strong in universality, wide in application scope, compact in structure, accurate in positioning and is suitable for large scale promotion.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

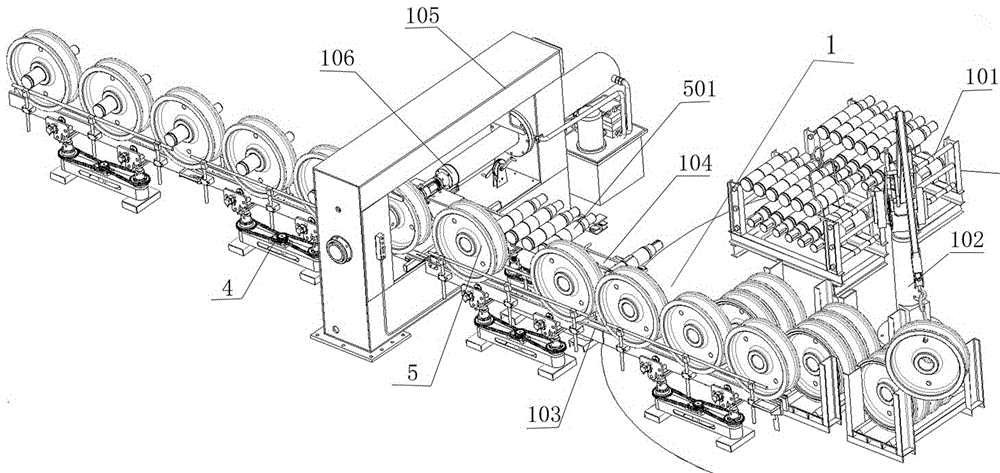

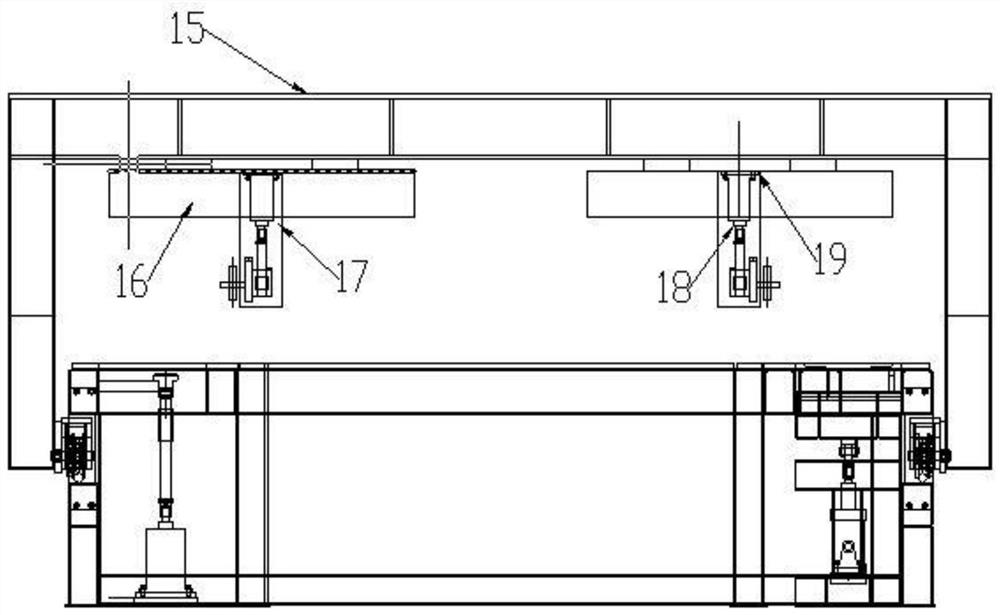

Flexible crane wheel assembly line

The invention discloses a flexible crane wheel assembly line which comprises a first station area, a second station area and a third station area, wherein the first station area is in charge of completing press fitting of wheels and wheel axles; the second station area is in charge of completing press fitting of corner boxes and bearing outer rings; and the third station area is in charge of completing press fitting or assembly of the wheels subjected to press fitting in the first station area, the corner boxes and bearing outer rings and accessories thereof subjected to press fitting in the second station area, as well as running-in test of finished products. Compared with the prior art, the flexible crane wheel assembly line disclosed by the invention mainly comprises three presses, two rollaway nests and other auxiliary equipment, the axles and wheels are subjected to press fitting together in the first station and can be transferred into the third station by the rollaway nests, and accessories such as through covers, spacer bushes and the like can be assembled on the rollaway nests; the corner boxes and bearing outer rings are subjected to press fitting together in the second station, the two bearing outer rings can be simultaneously pressed in, the bearings and bearing boxes are assembled on the wheels in the third station, and the accessories such as through covers, valve covers, standard fasteners and the like are assembled after press fitting completion.

Owner:HENAN WEIHUA HEAVY MACHINE

Hub pre-degreasing method

The invention provides a hub pre-degreasing method and relates to hub machining equipment and technology field. At first, prepared degreasing cleaning fluid is placed into a pool body and is distancedfrom the edge of the pool body by 20-30 centimeters; a hub is horizontally placed into the pool body and then soaked in the pool body for 30-60 minutes; after soaking is finished, an inflation pipe in the pool body is turned on, thus the cleaning fluid rolls over and flows constantly for 10-20 minutes under power of gas, the inflation pipe is turned off, after standing is carried out for 10-15 minutes, the inflation pipe is turned on for a second time to carry out flow disturbing on the cleaning fluid, after 10-20 minutes, the inflation pipe is turned off, and the cleaning fluid stands for 10-15 minutes; a cleaning pipe is turned on to clean a hub, after the hub is cleaned for 10 minutes, the cleaning pipe is turned off, and the hub stands for 20 minutes; the cleaning pipe and the inflation pipe are turned on at the same time, and after 30-45 minutes, the cleaning pipe and the inflation pipe are turned off; standing is carried out for 1-2 hours, and the hub is taken out. The method iseasy to operate, the hub does not need to be turned over manually, automatic cleaning and degreasing are achieved, time for standing and soaking can be shortened greatly, acting time of the cleaningfluid to the hub is prolonged, and the efficiency is improved.

Owner:BENGBU FUWOTE WHEEL MFG TECH

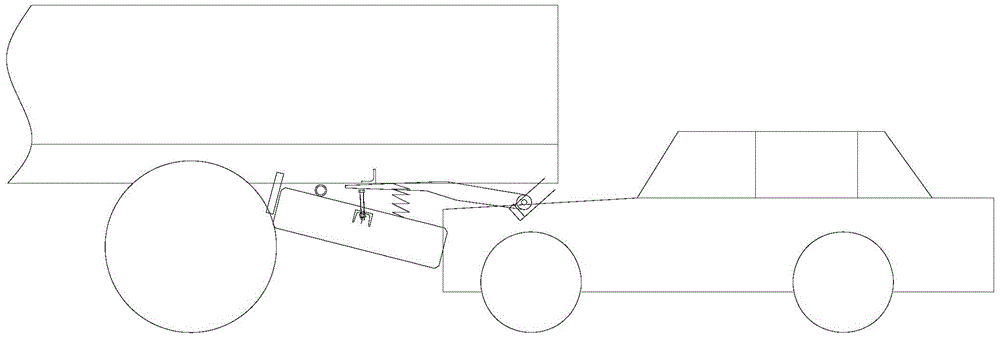

Truck rear-end collision protection device

ActiveCN104859571AFlip fastSave time flippingVehicular safety arrangmentsSpare wheel arrangementsRear-end collisionEngineering

The invention discloses a truck rear-end collision protection device, which comprises a fixed support frame, a spare wheel hanging mechanism, a spare wheel and a push rod, wherein the fixed support frame is fixedly arranged on a truck girder arranged at the bottom of a truck; the top of the spare wheel hanging mechanism is arranged on the fixed support frame; the axis part of the spare wheel is hung on the bottom of the spare wheel hanging mechanism; the upper end surface of the spare wheel is hinged onto the truck girder; one end of the push rod is connected with a truck rear bumper; the other end of the push rod is connected with the spare wheel hanging mechanism; and the push rod is used for driving the spare wheel to clockwise rotate around a hinging point of the spare wheel and the truck girder. The truck rear-end collision protection device has the advantages that when the rear-end collision occurs, the truck rear bumper is bent through being collided with a car; the push rod is driven to forwards move; the push rod drives the spare wheel hanging mechanism, so that the spare wheel clockwise rotates around the hinging point of the spare wheel and the truck girder; and when the car continuously advances, the spare wheel jacks the middle lower part of a car head of the car. The middle lower part of the car head of the car has high strength, and can bear greater impact force, so that the goal of preventing the car from entering the bottom of the truck through the spare wheel is achieved; and the car crash is avoided.

Owner:NANTONG INST OF TECH

Overweight main girder turnover device and turnover method

The invention relates to an overweight main girder turnover device, the turnover device is arranged at one end of a main girder and comprises a segment spliced by two semi-segments, the arc length of two semi-segments is different, and the semi-segments are connected by a connection board and bolts, a hole which couples with a cross section shape of the overweight main girder is provided at string; a turnover method for the overweight main girder is characterized in that the turnover device is fixed on the girder, and the turnover motion is completed through lifting of four traveling cranes. According to the invention, the load born by the main traveling crane can be mitigated, so that the lifting requirement of the traveling crane can be satisfied when a construction member is turned over (dynamic load operation), and the smooth turn-over of the construction member can be simultaneously ensured.

Owner:SHANGHAI BAOYE GRP CORP

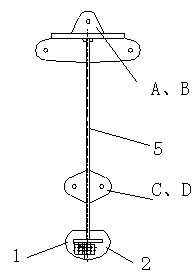

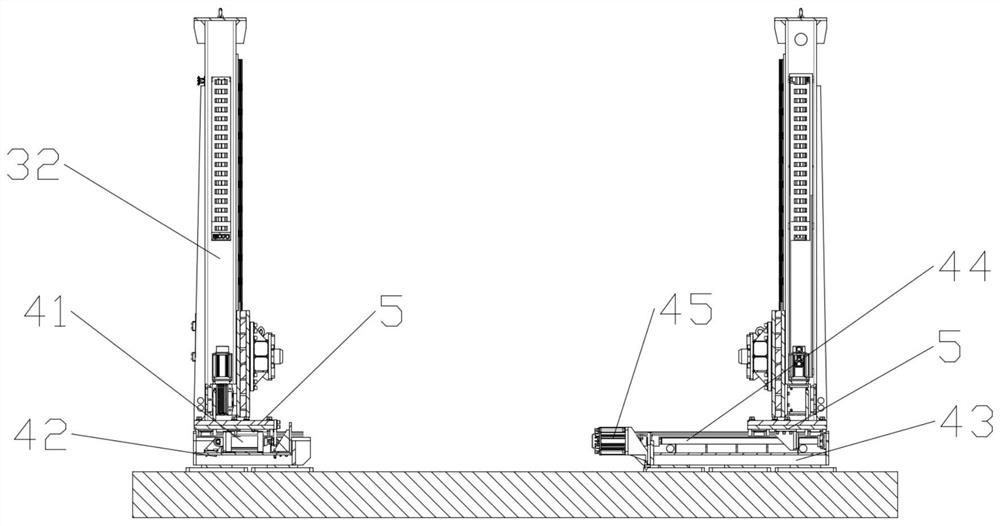

Method for synchronously lifting and overturning workpiece on two sides

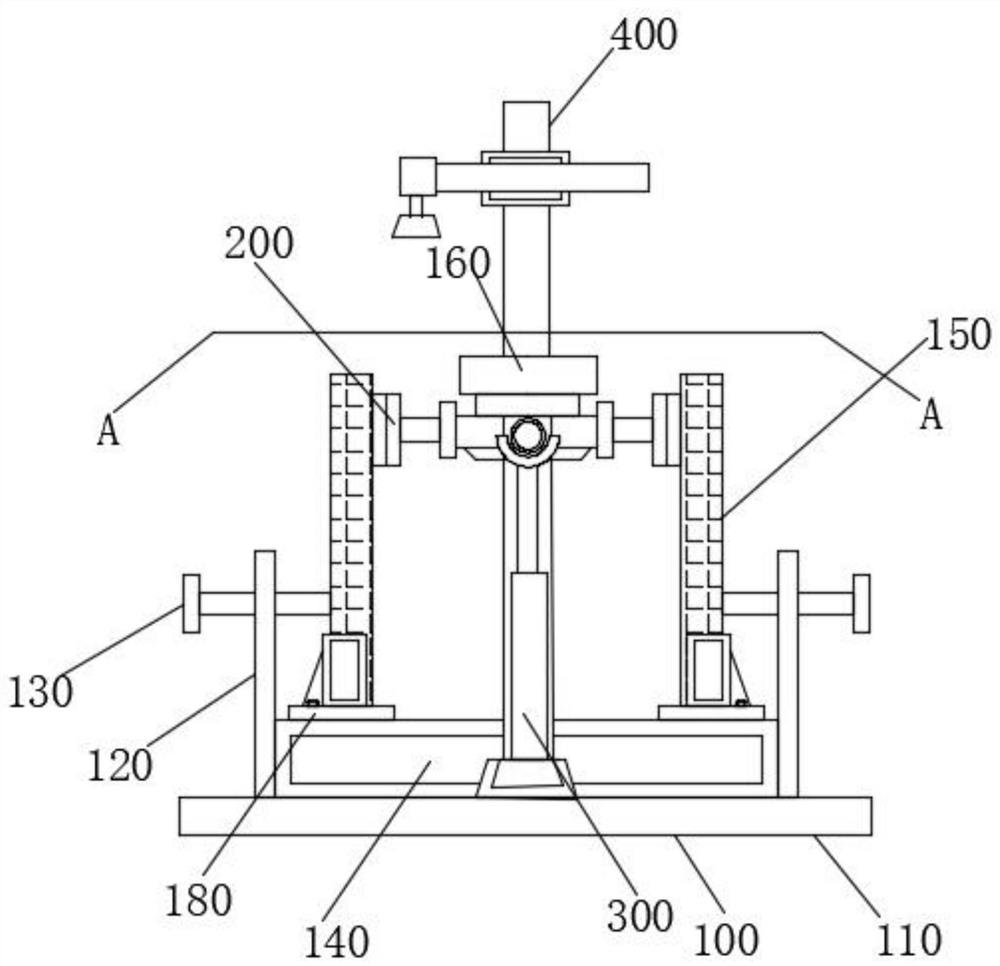

PendingCN113102941AHigh degree of automationPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesMachine buildingEngineering

The invention provides a method for synchronously lifting and overturning a workpiece on two sides, and relates to the technical field of mechanical manufacturing. The method for synchronously lifting and overturning the workpiece on two sides comprises the following steps: step 1, two horizontal movement assemblies are started, the horizontal movement assemblies move to enable lifting assemblies and rotating mechanisms to move towards the direction of the workpiece, and the rotating mechanisms move towards the direction of the workpiece to insert inserting blocks on two workpiece clamping assemblies into the long-strip holes of corner fittings of the workpiece, so that the workpiece is fixed between the two workpiece clamping assemblies; step 2, the two lifting assemblies are synchronously started, the lifting assemblies enable the rotating mechanisms to ascend, and the rotating mechanisms ascend to enable the workpiece clamping assemblies to drive the workpiece to ascend, so that the workpiece ascends to a safe position; step 3, the two rotating mechanisms are synchronously started, and the rotating mechanisms enable the workpiece clamping assemblies to drive the workpiece to turn over by an angle; and step 4, the two lifting assemblies are synchronously started; The device is high in automation degree and accurate in positioning, saves labor cost, is convenient to use, has few operation processes, and shortens overturning time.

Owner:郑州越达科技装备有限公司

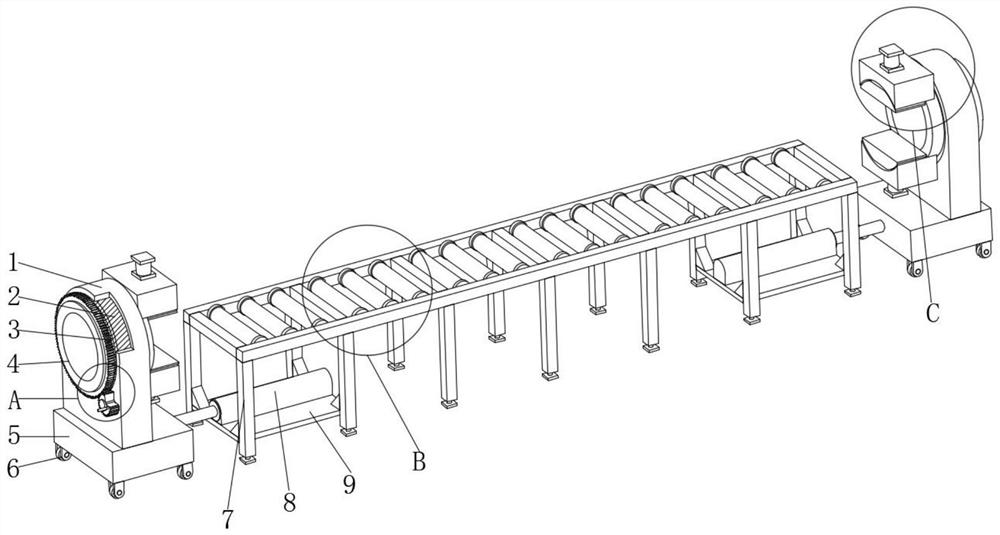

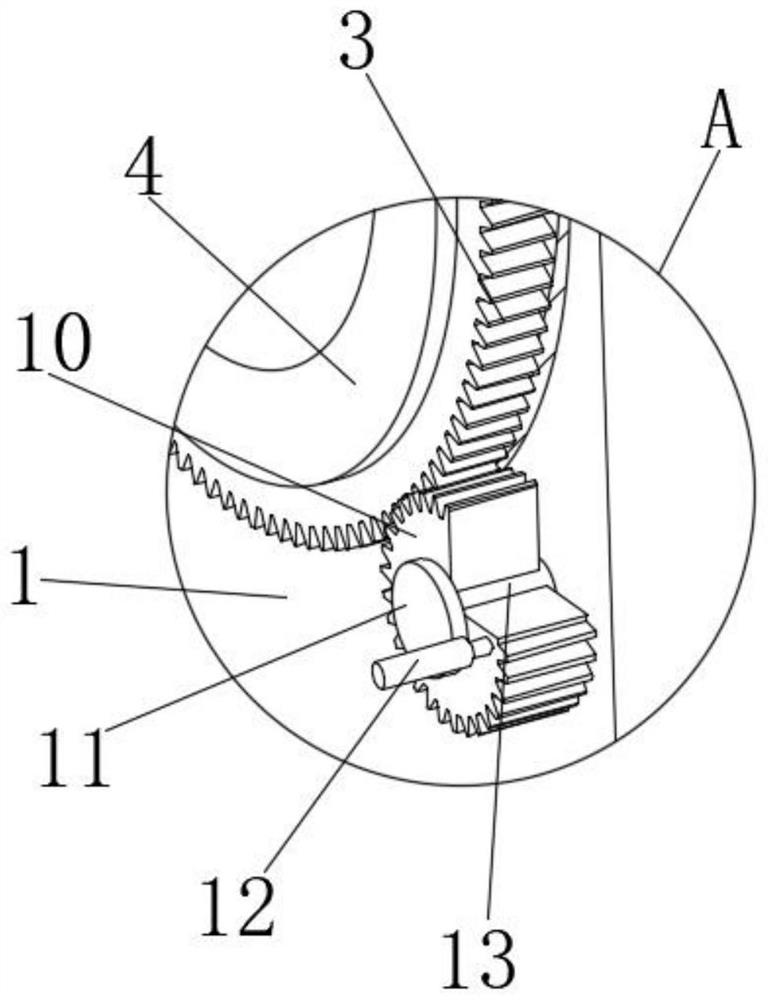

Multifunctional welding overturning device for trailer girder

InactiveCN112338431AEasy to weldAchieve the purpose of flippingWelding/cutting auxillary devicesAuxillary welding devicesGear wheelClassical mechanics

The invention relates to the technical field of overturning devices, in particular to a multifunctional welding overturning device for a trailer girder. The device comprises a supporting frame, wherein reciprocating components are installed at the two ends of the supporting frame, a supporting base is fixed to the upper portions of the reciprocating components, a bearing is fixedly installed in the upper end of the supporting base, and a cylinder is fixed into the bearing. One end of the cylinder extends out of the bearing to be provided with a rotating component, and the other end of the cylinder extends out of the bearing to be provided with a clamping component. A user operates a rocker to enable a gear to rotate, due to the fact that the gear is meshed with a gear ring, when the gear rotates, the gear ring is driven to rotate, then the cylinder is driven to rotate, the girder is driven to rotate through rotation of the cylinder, the overturning purpose is achieved, people can use the overturning device conveniently, and the overturning time is saved; and the working efficiency is improved, and workers can conduct welding more conveniently.

Owner:湖南宏弢科技有限公司

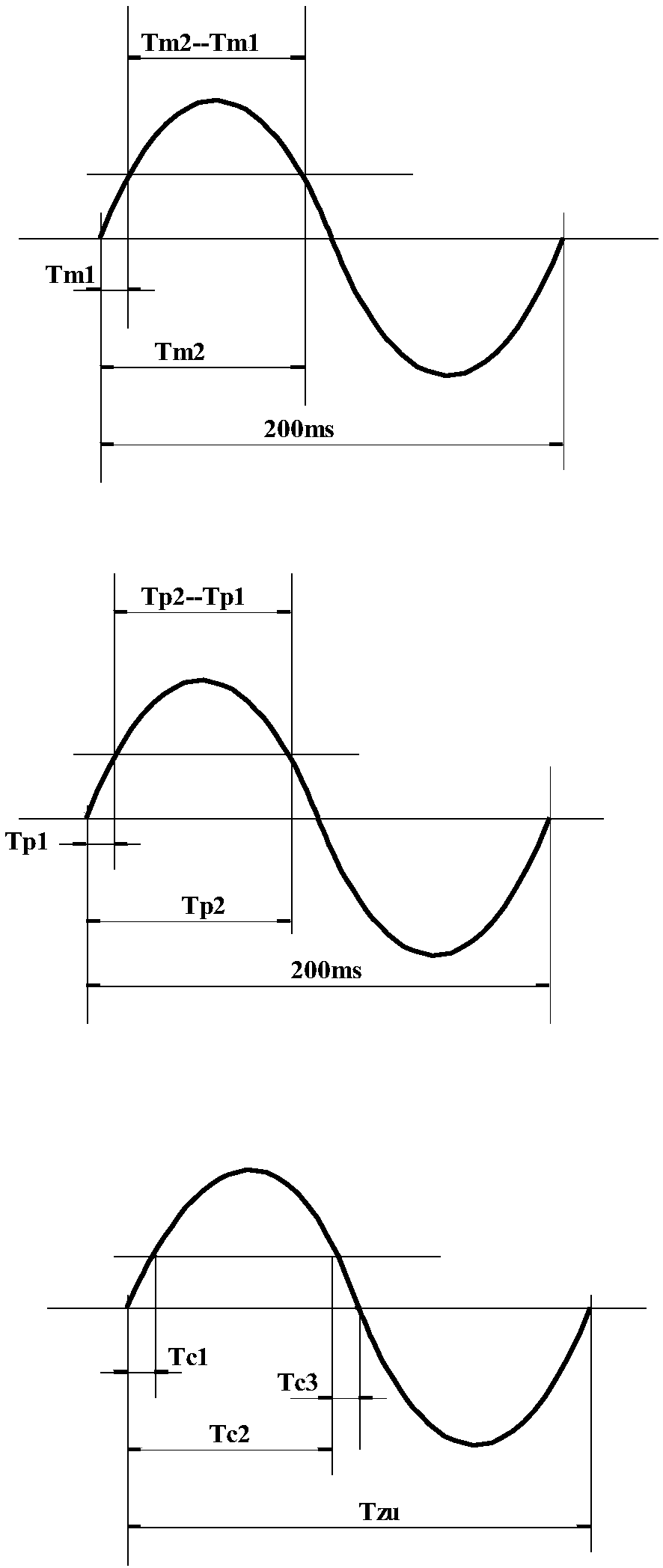

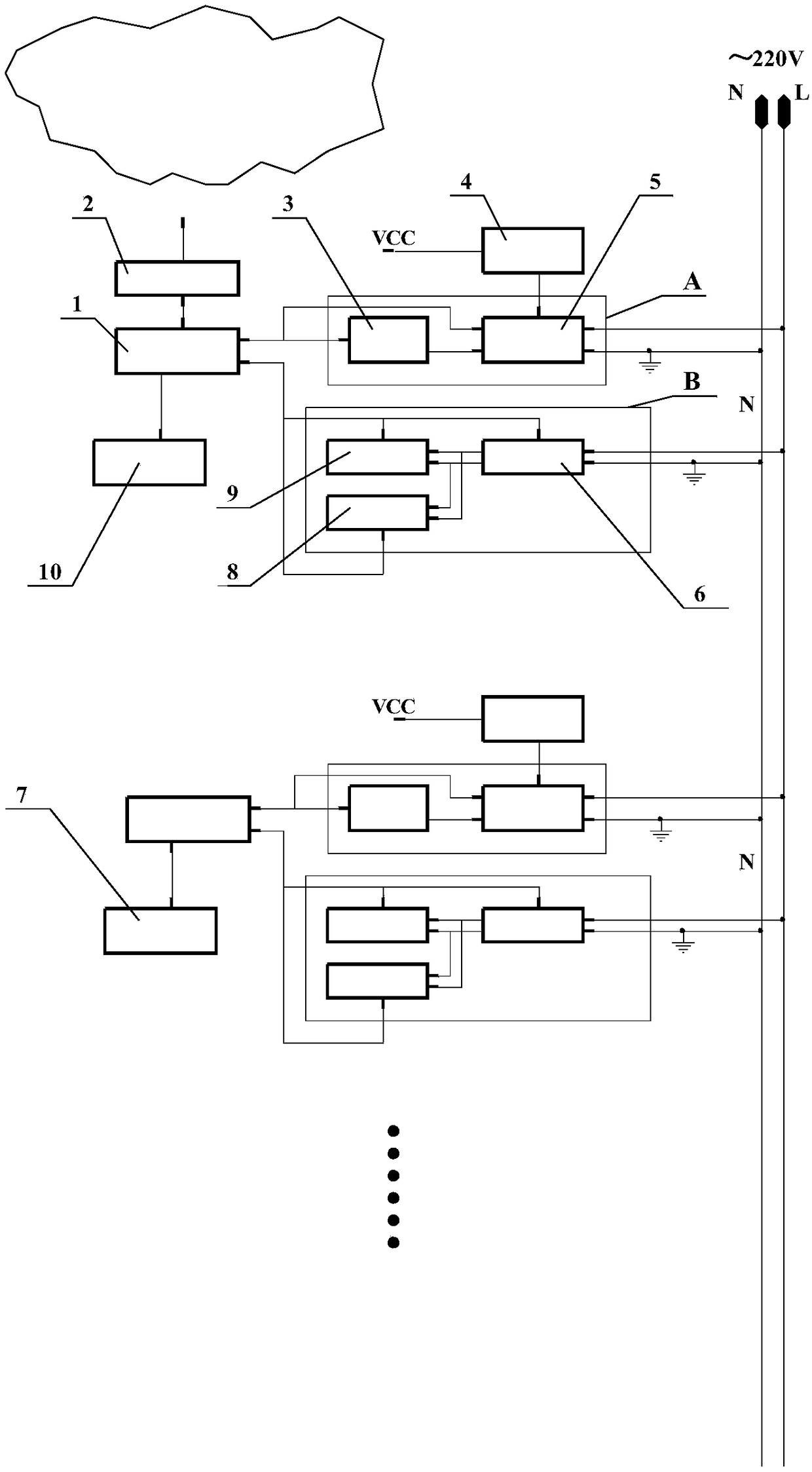

Remote control system for home automation

InactiveCN109035743ALower impedanceIncreased flipping timeElectric signal transmission systemsPower distribution line transmissionElectronic switchThe Internet

The invention relates to a remote control system for home automation, composed of a main controller, a small telephone exchanger and electronic switches of electric appliances. One small telephone exchanger is installed in a home, and one of extension numbers is used for remote control on the electric appliances. A master sends a number of an instruction code from a telephone or mobile phone, theexchanger transmits a received digital signal of the instruction code to the main controller via an interface circuit, the digital signal is decoded by the main controller, and then the main controller executes corresponding on-off and timing operations on the electronic switch of each electric appliance through power line communication. The main controller is also accessed to the Internet by virtue of a network interface module and controls the electric appliances in the home by a remote computer.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

Fire disaster alarm control system

InactiveCN108961705ALower impedanceIncreased flipping timeParticular environment based servicesAlarmsFire detectorControl system

The invention relates to a fire hazard alarm control system which comprises fire hazard detectors, regional controllers, a concentrated controller and a fire extinguishing controller. After power-on,the regional controllers registers the fire hazard detectors, and raises alarm when a fault is found. Each fire hazard detector grades a detected fire alarm signal and then sends alarm information tothe corresponding regional controller, and the regional controllers raise alarm to the concentrated controller via power line communication according to the position and grade of the fire alarm, and the concentrated controller starts fire extinguishing apparatuses and emits alarming sound via power line communication or by starting the fire extinguishing controller.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

Smart home remote control system

InactiveCN108983663ALower impedanceIncreased flipping timeProgramme controlComputer controlWireless routerControl system

The invention relates to a smart home remote control system. The output of each electric appliance controller is connected in series with the circuit of the original socket or switch of a household electric appliance, so that the load power and the power-on time of the household electric appliance can be controlled. A utility program is preset in the electric appliance controller to enable ordinary electric appliances to operate intelligently. Each electric appliance controller has a unique number. A main controller communicates with the electric appliance controllers via a power line and alsogets access to the 4G mobile wireless communication network via a wireless router. A user can get access to and control the household electric appliances by a mobile phone, a computer or a handheld mobile device wherever he / she is.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

Remote control system of household electrical appliances

InactiveCN108897295ALower impedanceIncreased flipping timeComputer controlProgramme total factory controlElectronic switchHand held

The invention relates to a remote control system of household electrical appliances. Electrical appliance controllers control start-up and shut-down of the electrical appliances of air conditioner equipment and the like through electronic switches. A small telephone program-controlled exchanger is installed in a house, one of extension numbers is used for remote control, the exchanger receives number signals of instruction codes and transfers the number signals of the instruction codes to an integrated controller, and after decoding is conducted by the integrated controller, corresponding operation is executed. The integrated controller has access to the Internet through a network interface module so that a computer and hand-held mobile equipment can be used for visiting a remote computermanagement system.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

Bionic flapping wing micro aircraft capable of realizing controllable flapping amplitude based on wing root elastic energy storage

PendingCN113911342AHigh transmission efficiencyReduce energy dissipationOrnithoptersWing rootFlight vehicle

The invention discloses a bionic flapping wing micro aircraft capable of realizing controllable flapping amplitude based on wing root elastic energy storage. A wing root elastic stop structure is introduced into the aircraft, inertia work of flapping of a wing rod is stored as elastic potential energy in the flapping ending stage and the flapping starting stage, the elastic potential energy is released in the next flapping initial stage of a flapping wing, on one hand, the transmission efficiency of the aircraft is improved, and energy dissipation of the aircraft is reduced; on the other hand, the motion of the flapping wings in the upward flapping and downward flapping motion conversion process is accelerated, the overturning time of the flapping wings is shortened, and therefore the aerodynamic efficiency of the flapping wings is improved; meanwhile, through three rotary steering engines, pulleys and cams, differential adjustment of flapping amplitude of the flapping wings can be achieved under the condition that operation of a transmission mechanism is not changed, bionic flapping control motion is achieved, and three-axis controllable flight of the bionic flapping wing micro aircraft is achieved.

Owner:BEIHANG UNIV

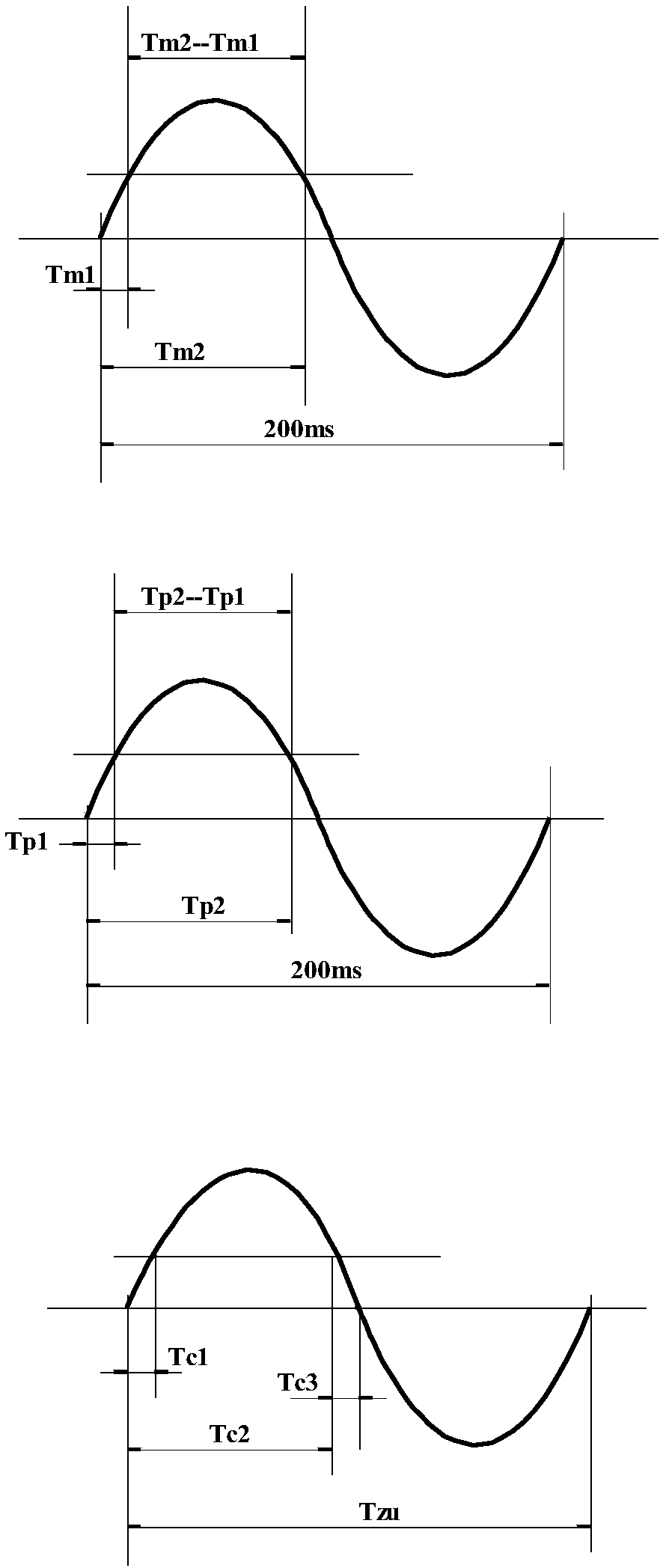

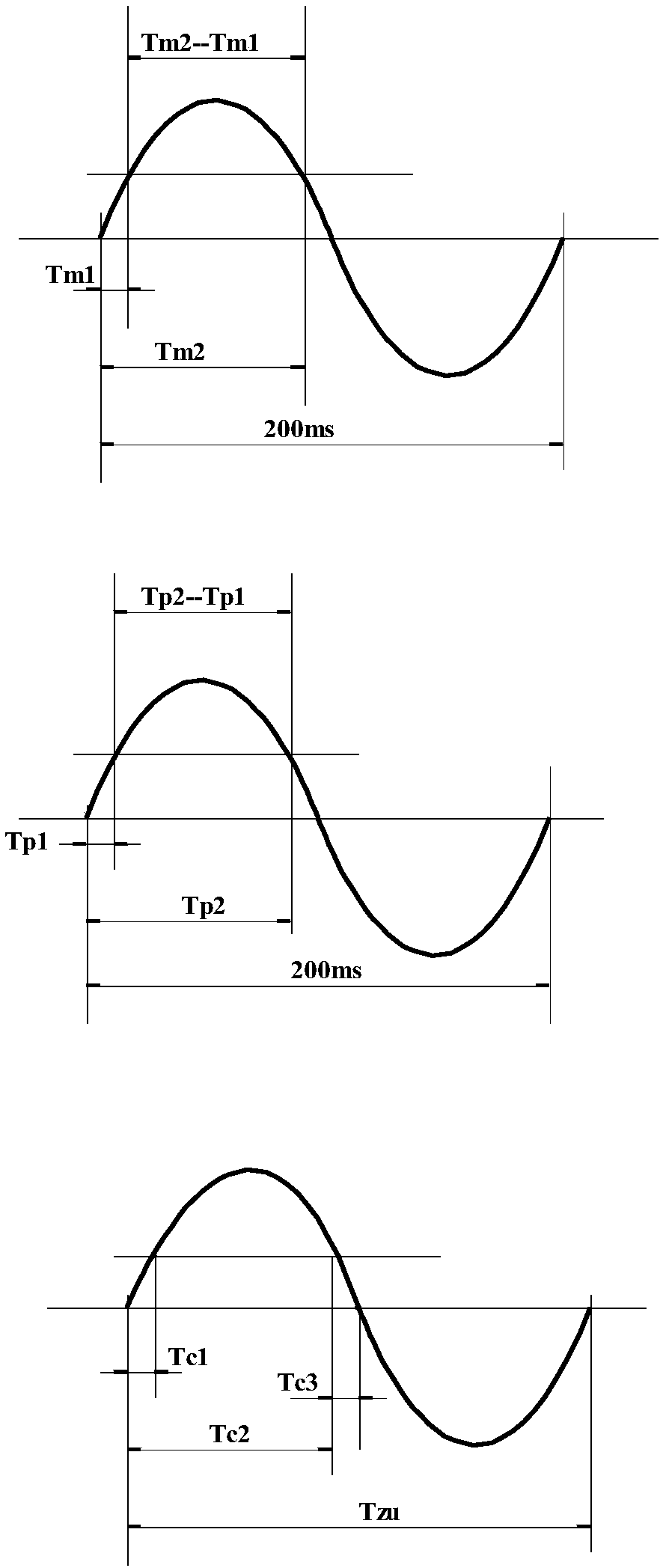

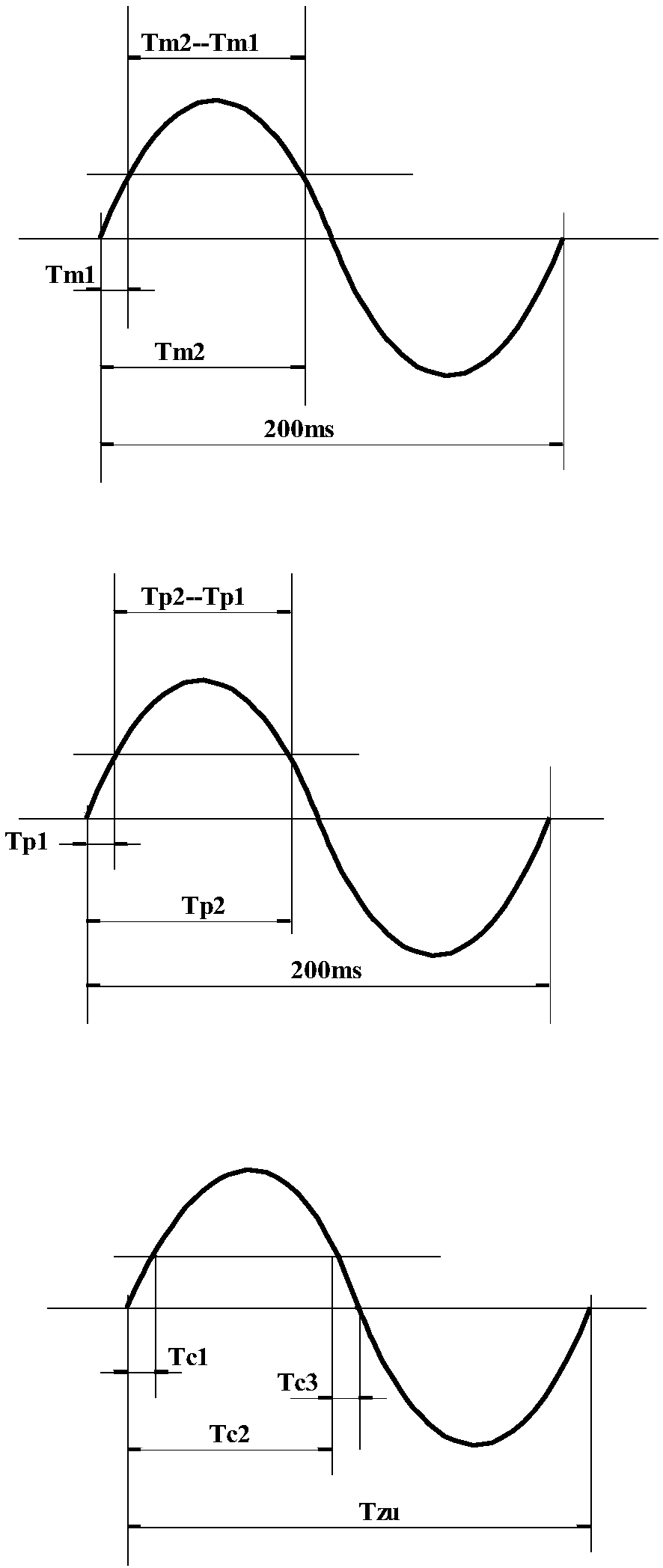

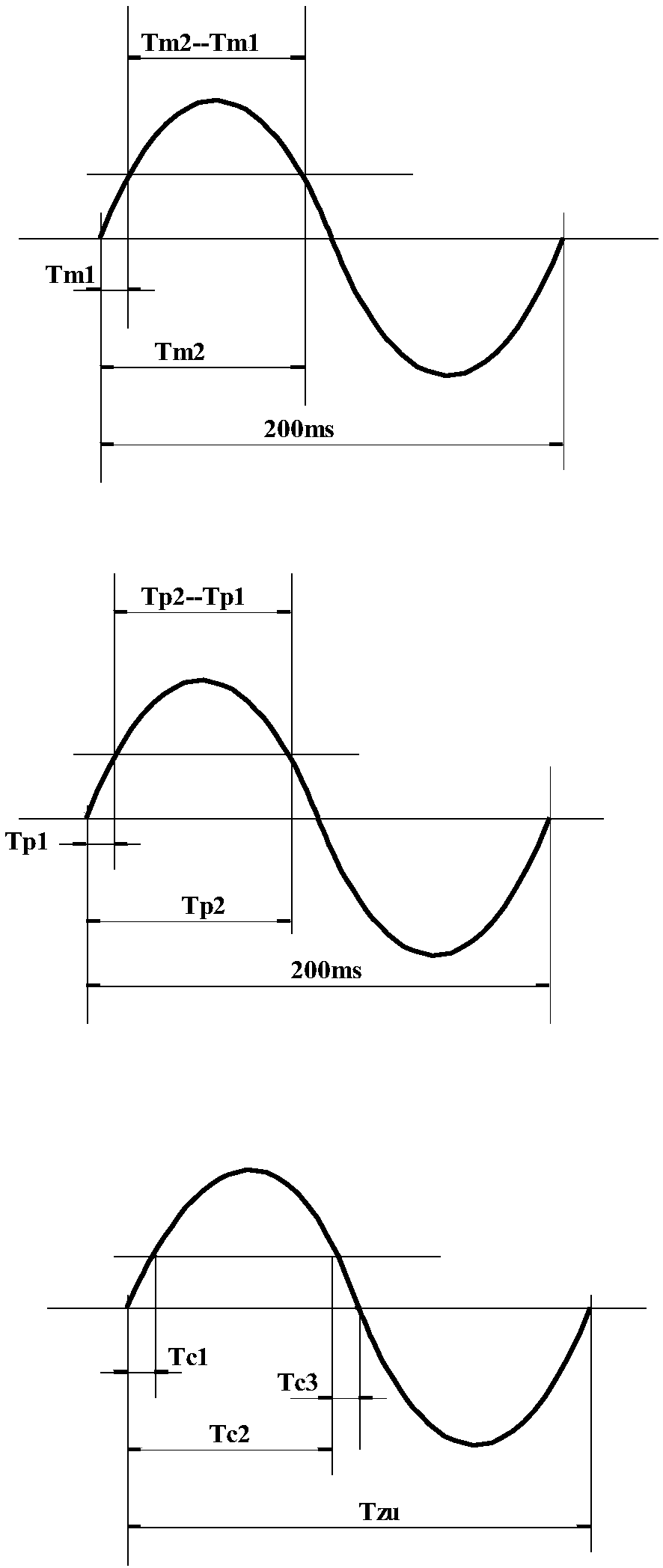

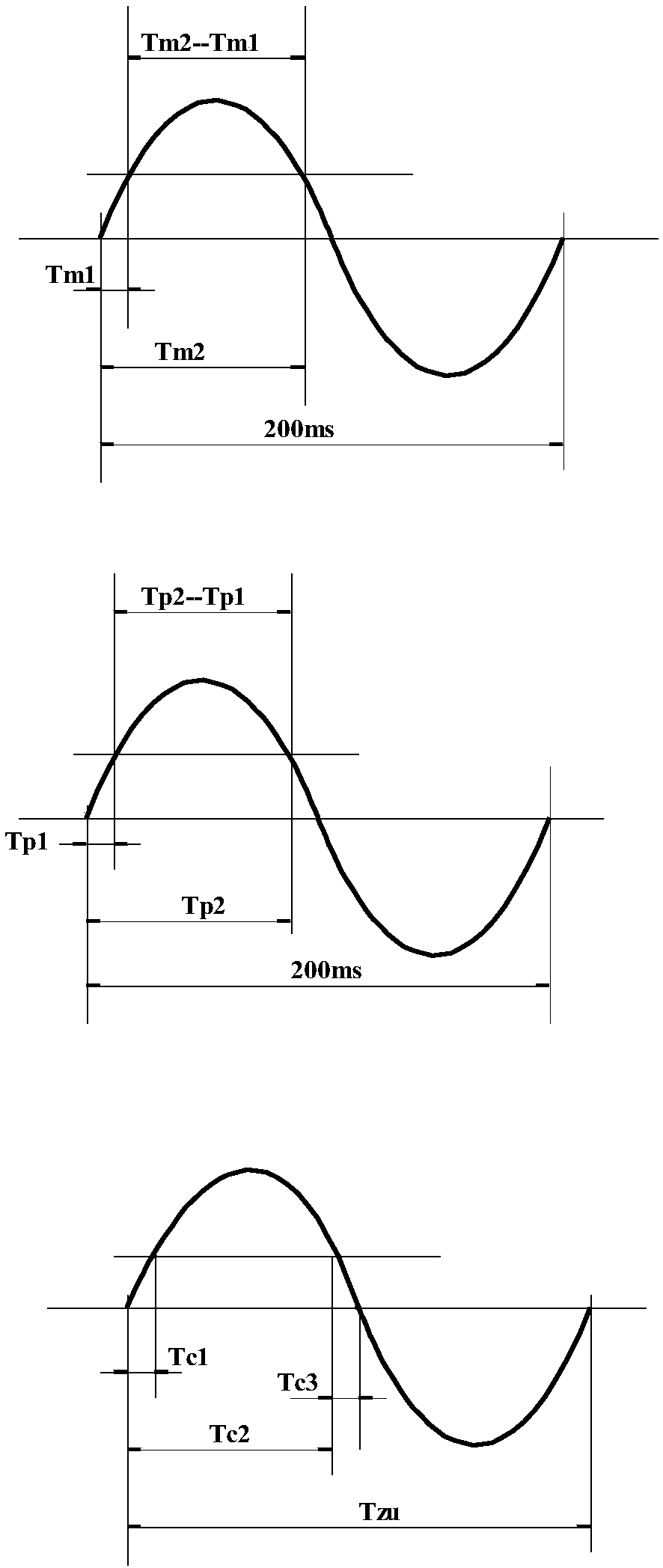

Electric energy measurement and automatic meter reading system for residential area

InactiveCN108877192ASecure high-speed wireless connectionReduced wiring engineeringElectric signal transmission systemsData acquisitionEngineering

The invention relates to an electric energy measurement and automatic meter reading system for a residential area. A broad pulse signal is sent to a specific point of a cycle voltage 0-exceeding region of a power grid by utilizing a centralized controller and data acquisition units through a power line communication method, so as to generate mutation current; the mutation current is used as a bitvalue of the signal; data acquired by each data acquisition unit is received by the centralized controller and is accessed into a 4G mobile wireless communication network through a wireless router, sothat wireless networking can be realized by utilizing a mobile phone, a computer and handheld mobile equipment at any where.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

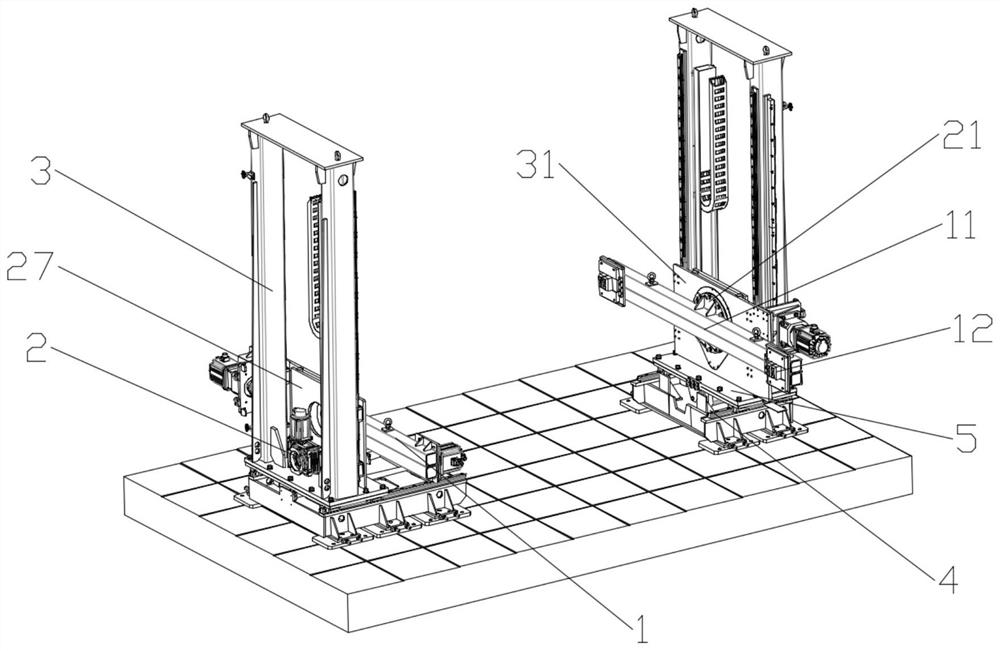

Special automatic welding machine for reinforcing ring web splicing

PendingCN113441888ARealize automatic weldingSave time flippingWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryWeld seam

The invention discloses a special automatic welding machine for reinforcing ring web splicing. According to the special automatic welding machine for reinforcing ring web splicing, walking wheels are arranged at the lower ends of two vertical beams of a portal frame correspondingly, one walking wheel is connected with a motor A, and the walking wheels can walk on a portal frame base; a plurality of working supporting plates are placed on the gantry frame base, reserved copper liner installation grooves are formed in the positions, at the splicing weld joints, of the adjacent working supporting plates, and copper liners are placed in the installation grooves; and a positioning plate is arranged on the working supporting plates. The walking gantry, a fixed rail and a transverse sliding table are matched, and longitudinal and transverse automatic welding is achieved; one-side welding and double-side forming of a splicing weld joint can be achieved through the copper liners of forming grooves, and meanwhile the time for overturning each time and the time for correcting a rail are saved; the reinforcing ring web can be conveniently positioned through the positioning plate conforming to the reinforcing ring web; and through an opening pressing mechanism, the stability of the reinforcing ring web in the welding process is guaranteed, and then the straightness of a web splicing welding seam and the copper liner is guaranteed.

Owner:大连中车大齐集装箱有限公司

Customer guiding system of mall commodities

InactiveCN108964711ALower impedanceIncreased flipping timeElectric signal transmission systemsPower distribution line transmissionEngineeringSerial code

The invention relates to a customer guiding system of mall commodities. The commodity species are frequently changed in the mall with variety of commodities, the mall layout is complex and more curved-channels, floors and partition spaces are existent; the guiding system can help the customer finding the location of the required commodity; the mall planar graph comprises various commodity area names, shelf serial numbers, and LED serial number arrows arranged at passages and the corners; the customer can understand the commodity condition or order the commodity from the mall at any time by downloading the mobile phone APP software from the official website of the mall.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

Chain store customer inquiry system

InactiveCN108964707ALower impedanceIncreased flipping timeElectric signal transmission systemsPower distribution line transmissionWireless routerMobile apps

The invention relates to a chain store customer inquiry system. The store is divided into a number of commodity areas by product type; each commodity area comprises a plurality of shelves; several shelves share one commodity entry instrument; and the commodity entry instrument communicates with a centralized collector by using a power line. The centralized collector is connected to a mobile wireless communication network through a 4G wireless router; managers and customers can use mobile APPs, computers and handheld mobile devices to learn the details of the commodities of all stores no matterwhere they are.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

Home mobile phone intelligent control system

InactiveCN108810287ALower impedanceIncreased flipping timeElectric signal transmission systemsPower distribution line transmissionMaster stationMonitoring system

The invention relates to a home mobile phone intelligent control system. Devices such as a home security and protection monitoring system and home electrical appliances are all controlled by corresponding electrical controllers. A main controller collects indoor state information through power line communication, communicates with the electrical controller through power line communication, and transmits the indoor state information to a master station controller through a 4G mobile wireless communication network; the user views the indoor condition at any time through a mobile phone APP and can also can control the operation of the home interior appliances through the mobile phone APP.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

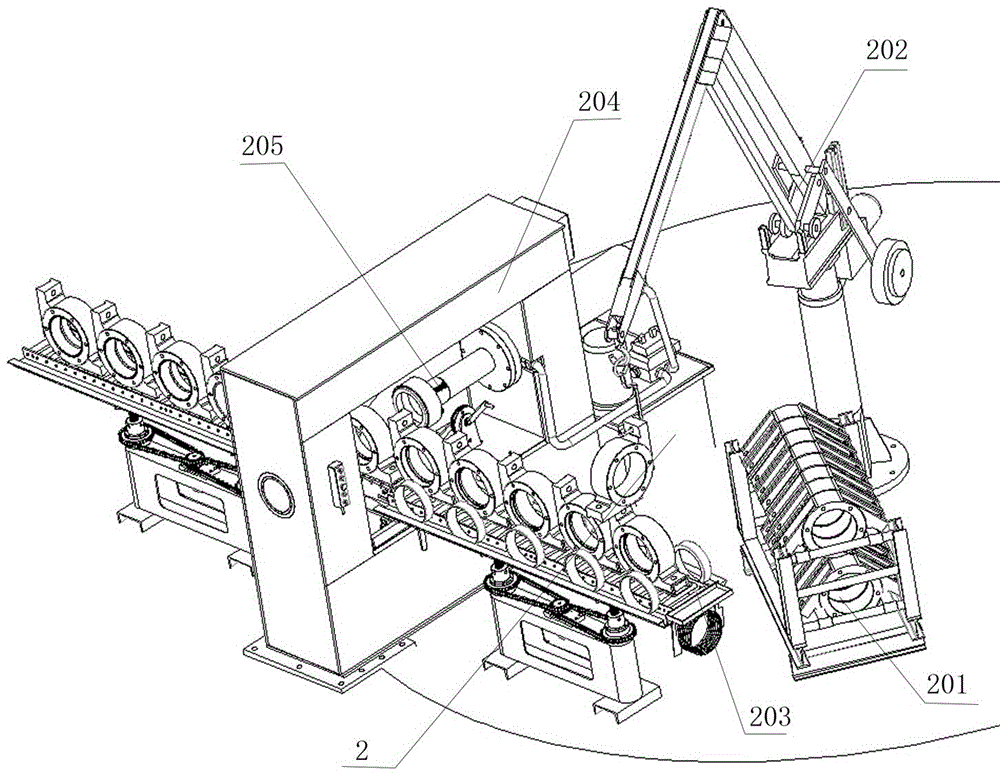

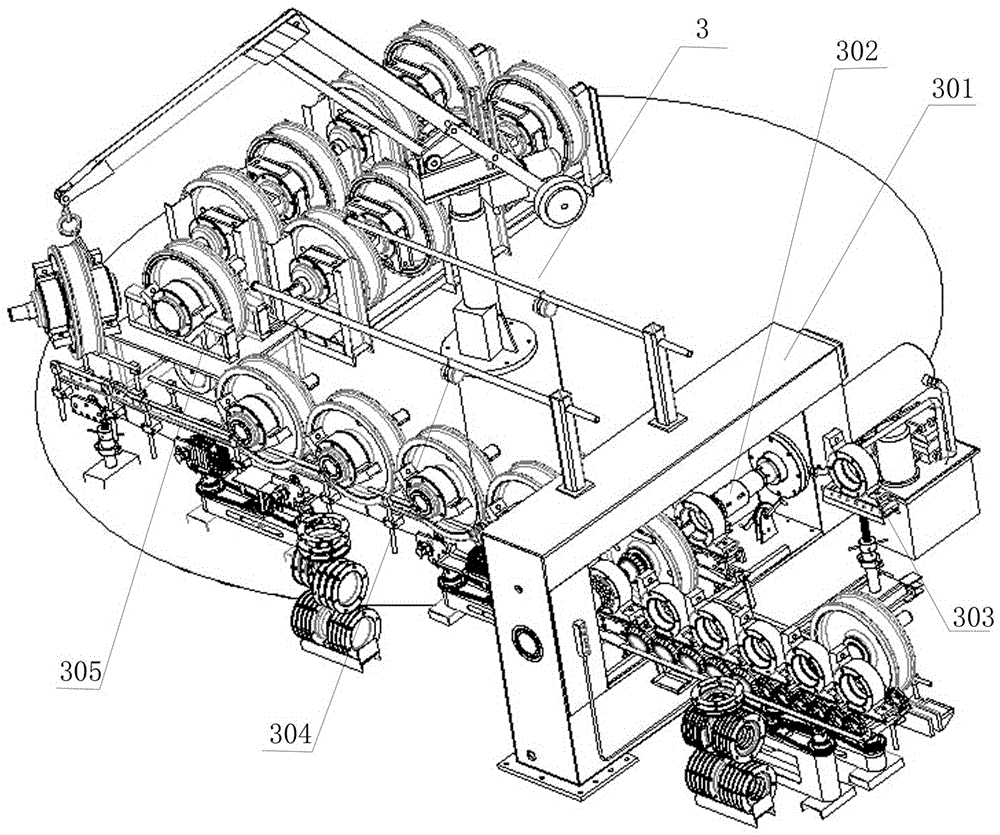

Double-arm four-wheel polling robot mechanism

The invention relates to a mobile robot, in particular to a double-arm four-wheel polling robot mechanism comprising a box body, a front arm mechanism and a rear arm mechanism, wherein the front arm mechanism and the rear arm mechanism are of the same structure and are respectively installed on the box body; each arm mechanism comprises travelling mechanisms, turnover mechanisms, an elevating gear, a clamping mechanism and a supporting arm, wherein one end of the supporting arm is connected with the box body, and the other end of the supporting arm is hinged with the elevating gear the two ends of which are respectively provided with the front turnover mechanism and the rear turnover mechanism; the front travelling mechanism and the rear travelling mechanism which can be turned over to the vertical state from the horizontal state are respectively connected to the output end of the front turnover mechanism and the output end of the rear turnover mechanism; the front travelling mechanism, the rear travelling mechanism, the front turnover mechanism and the rear turnover mechanism are linked with the elevating gear; and the clamping mechanism which is installed on the supporting arm and can clamp earth wires by moving up and down is arranged just below the front travelling mechanism and the rear travelling mechanism. The robot mechanism provided by the invention has the advantagesof good safety protection performance, strong crawling and obstacle-detouring capability, large working space, wide application range and the like.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +1

A workpiece turning device

InactiveCN105439057BReduce vibrationPrecise positioningLifting devicesHoisting equipmentsFixed frameMechanical equipment

The invention discloses a workpiece turnover device, and relates to mechanical equipment, in particular to the workpiece turnover device for overturning assembled T-shaped or H-shaped steel and several special cylinders and pipes with greater outer diameters and weights and shorter lengths by 0-180 degrees and applied to overturning movement of movable workpieces, in particular applied to such stations as welding turnover, correcting turnover, assembling turnover, flaw detection and manual welding. The workpiece turnover device comprises a base and a frame; the frame includes a fixed frame and a movable frame; the fixed frame is fixed on the base; the movable frame is movably connected with the base through a guide rail; an L-shaped first rotating arm is rotationally connected with the fixed frame through a rotating shaft A; and an L-shaped second rotating arm is rotationally connected with the movable frame through a rotating shaft B, and can perform a translational motion along with the movable frame. The workpiece turnover device has the advantages of safety, light turnover, difficult workpiece damage and deformation, low labor intensity of workers and high production efficiency.

Owner:WUXI LUSHENG MACHINERY EQUIP

Measurement and control system for aquaculture seedling raising bases

InactiveCN108646646ALower impedanceIncreased flipping timeProgramme controlComputer controlControl systemWater temperature

The invention relates to a measurement and control system for aquaculture seedling raising bases. Water temperature,air temperature and other change conditions need to be observed for a long time forsome large-scale aquaculture or seedling raising experimental bases,if an abnormality occurs,alarm processing is conducted in time,and a measurement and control instrument starts corresponding execution equipment to restore measured parameters within a set value range. Each monitoring area is provided with a centralized controller,the measurement and control instrument uploads measured data to thecentralized controller through power line communication,and management personnel use a mobile phone APP and a computer to access a computer management system of a main station and know the conditionsof all the monitoring areas.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

A data acquisition and management system for power consumption of factories, mines and enterprises

InactiveCN109004955ALower impedanceIncreased flipping timeElectric signal transmission systemsPower distribution line transmissionData acquisitionThe Internet

The invention relates to a power consumption data acquisition management system of a factory, a mine and an enterprise, wherein each group of power consumption equipment is provided with an electric quantity collector to collect power consumption information of a plurality of power consumption equipment, and each power consumption equipment is provided with a voltage transformer and a current transformer. The current and voltage signals collected by the electric quantity collector are conditioned and amplified and sent to the A / D converter for various electric energy calculation, and uploadedto the centralized controller through power line communication, and then integrated by the centralized controller through the network interface module integrated with TCP / IP hardware protocol stack toaccess the Internet, so that the remote computer management system can be accessed by the computer and handheld mobile devices.

Owner:FUZHOU ZHUNDIAN INFORMATION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com