Skateboard pneumatic assembling device

A sliding plate, pressing device technology, applied in auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of large splicing welds, high labor intensity, complex structure, etc., to improve efficiency and reduce labor intensity. , the effect of reducing the flip time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

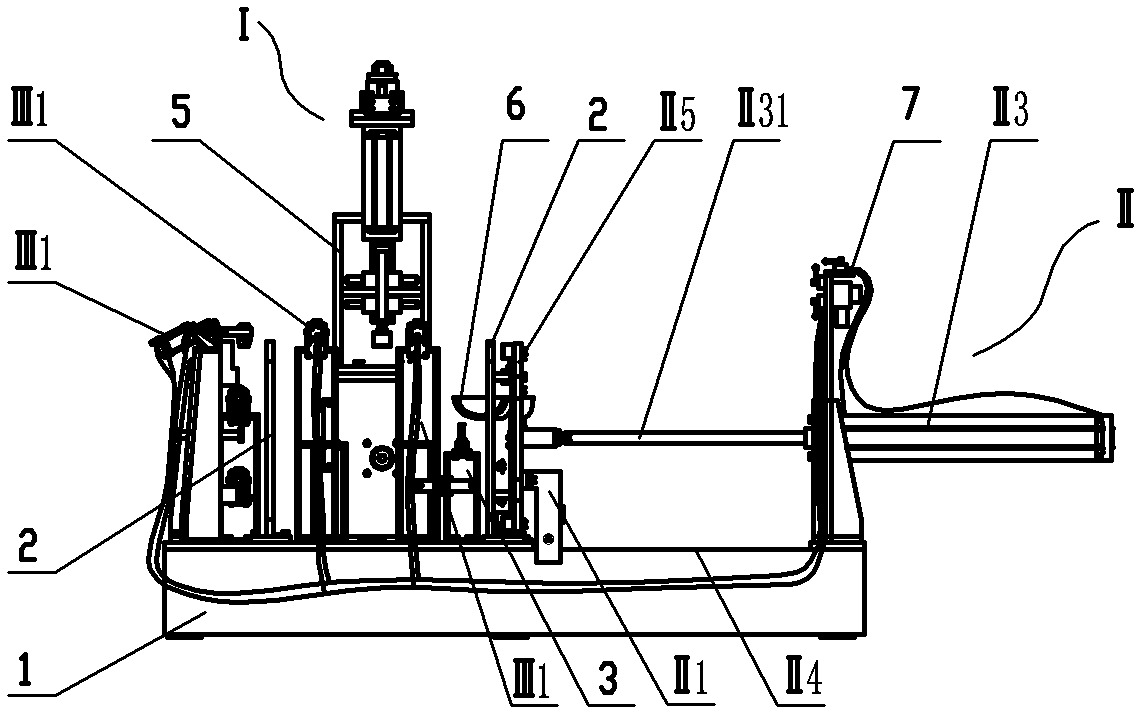

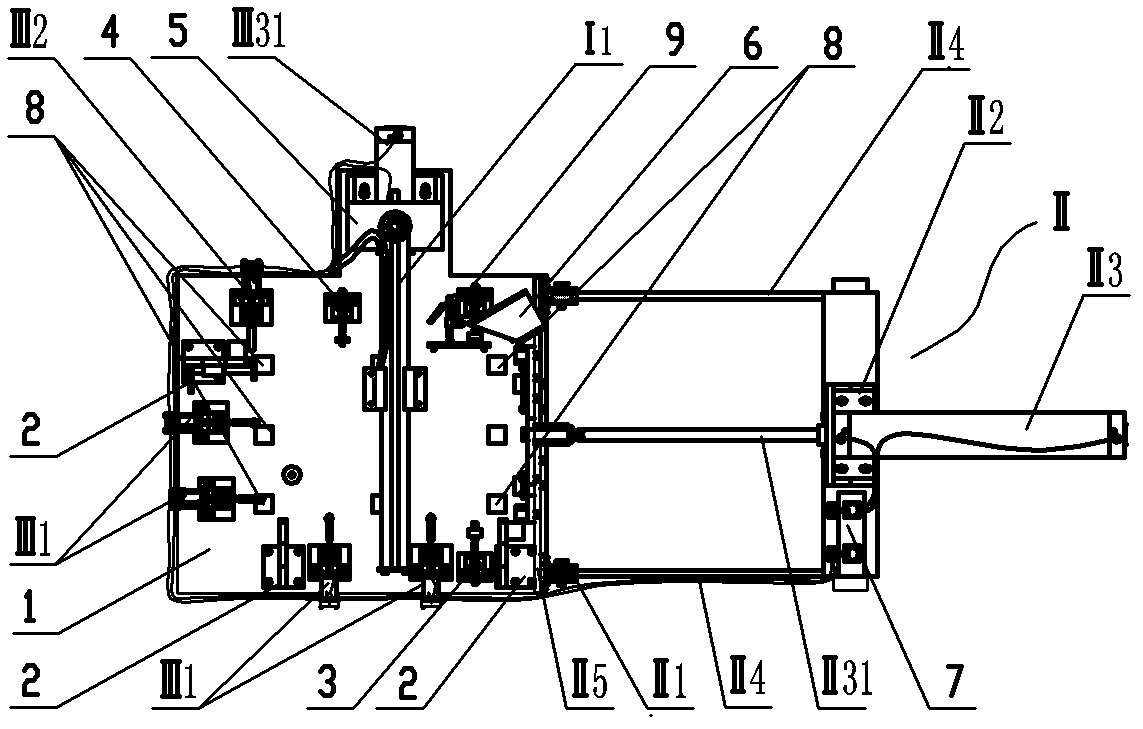

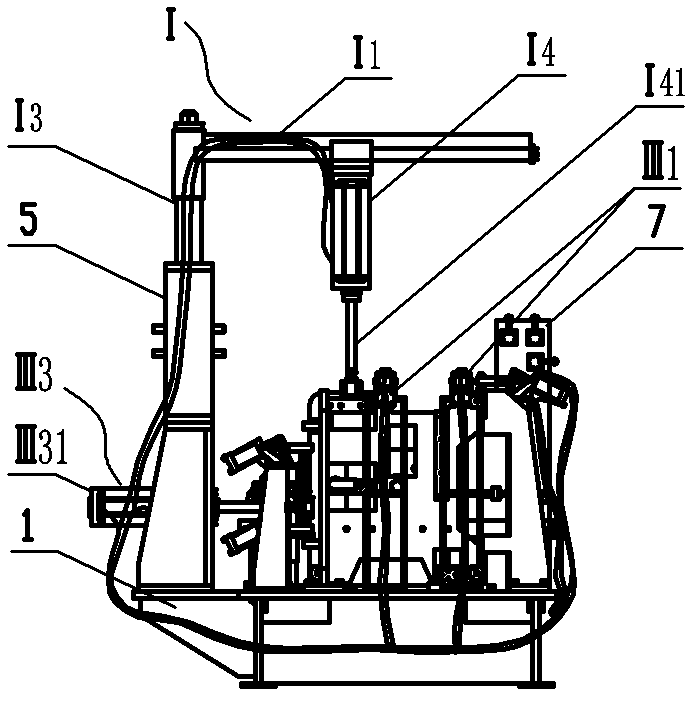

[0036] A skateboard type pneumatic erecting device, comprising a frame 1, a positioning seat 2 installed on a tooling platform 101 of the frame, a sliding plate pressing mechanism I, a cover plate pressing mechanism II, a coaming plate pressing mechanism III and a control system, The middle of the tooling platform is the workpiece station to be spliced. The positioning seat 2, the cover plate pressing mechanism II and the coaming plate pressing mechanism III are respectively located on the front side, left side, On the right side or the rear side, the slide plate pressing mechanism I is located on the upper part of the tooling platform;

[0037] There are three positioning seats 2 for stably supporting and positioning the bottom plate welded with the side plate, which are respectively installed on the front side and the left side of the rack tooling platform 101;

[0038] The sliding plate pressing mechanism I used to press any part of the upper part of the fuel tank to be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com