An external support welding tool for the connection nozzle of the shielding cylinder and its application method

A technology of welding tooling and shielding tube, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of affecting the arc degree, large sleeve diameter, and deformation of the shielding tube, so as to prevent local deformation, The effect of uniform welding stress distribution and deformation prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

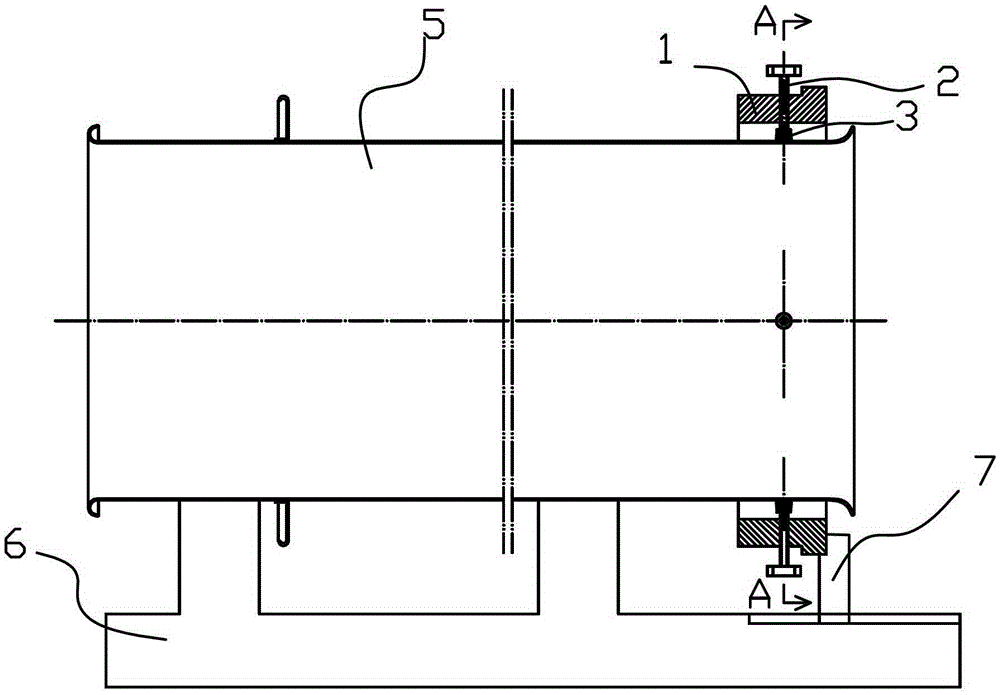

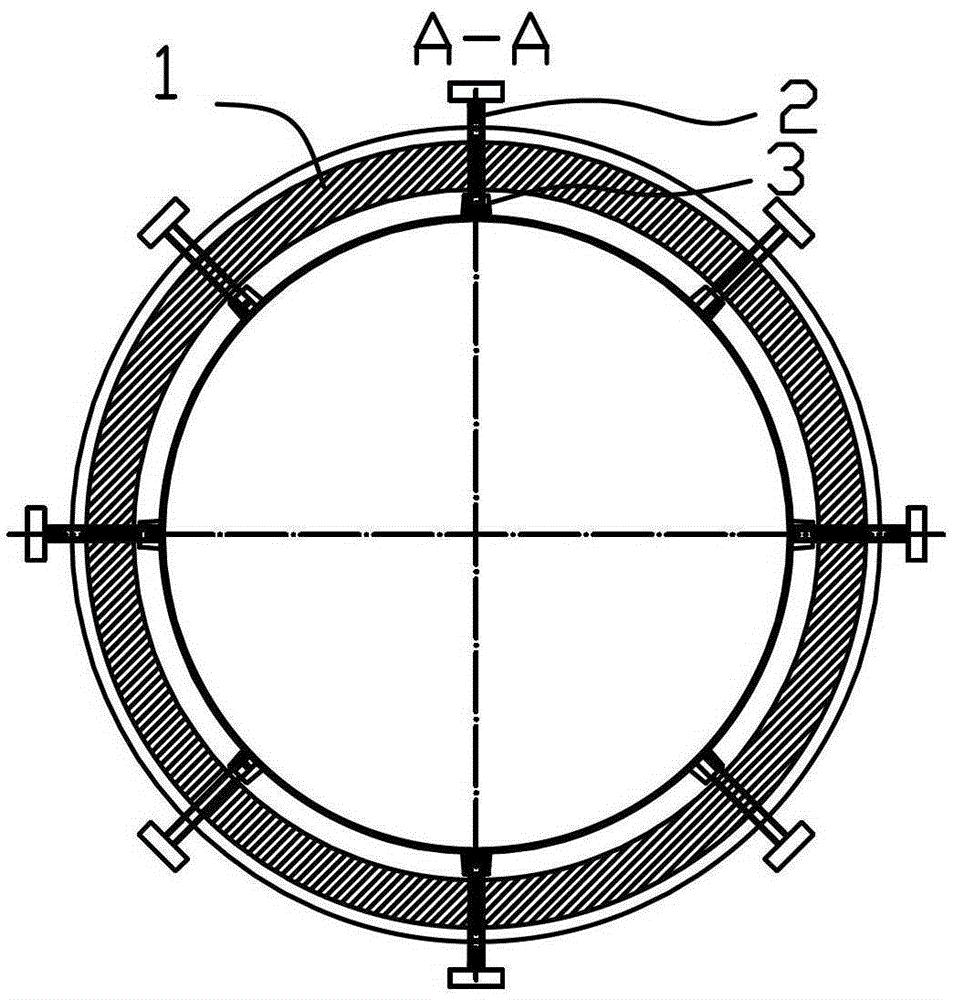

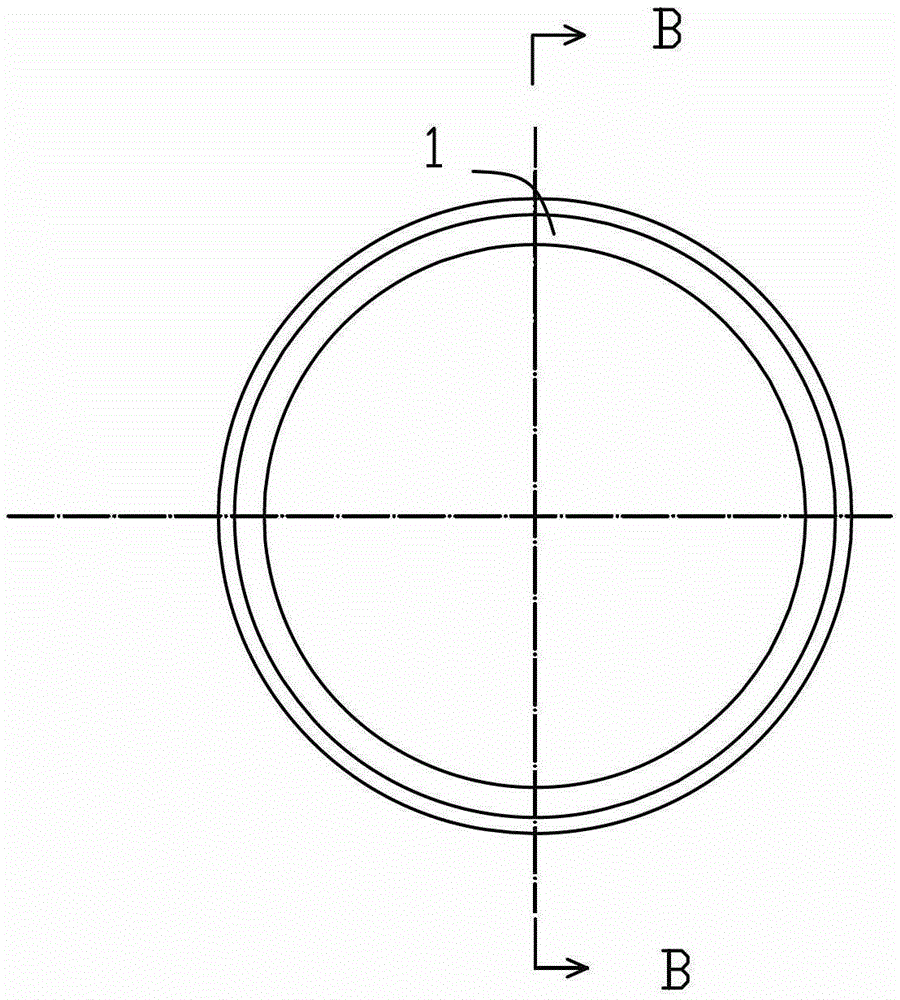

[0023] like Figure 1-4 As shown, the outer support welding tool of the shielding tube connecting nozzle, one end of the shielding tube 5 has a bell mouth, the connecting nozzle 3 is located inside the bell mouth, and the outer supporting welding tool includes a flange 1 and a retractable Screws 2, at least four threaded through holes 4 are evenly distributed around the flange 1, and the retractable screws 2 are arranged in the threaded through holes 4; the inner diameter of the flange 1 is greater than or equal to the horn of the shielding tube The maximum diameter of the mouth; the height of the connecting nozzle 3 ≤ the difference between the outer diameter of the shielding cylinder and the inner diameter of the flange; the connecting nozzle 3 is provided with a threaded hole for connecting the retractable screw 2. In addition, it also includes a positioning workbench, the table of the positioning workbench is provided with a fixed bracket 6 for supporting the shielding tub...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com