Punching sealing device for composite sealed bearing

A technology of bearing stamping and composite sealing, which is applied in the field of bearing manufacturing, can solve problems such as low efficiency, and achieve the effects of cost saving, high efficiency, and convenient and flexible installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

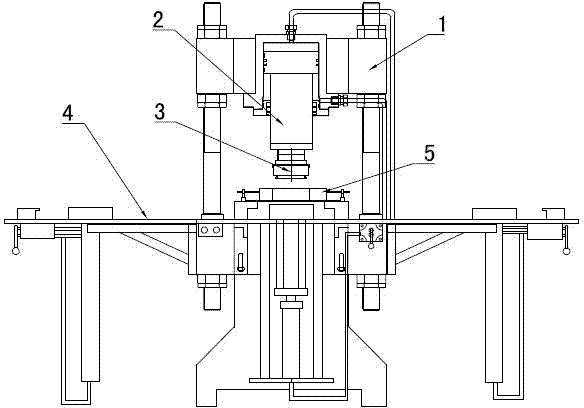

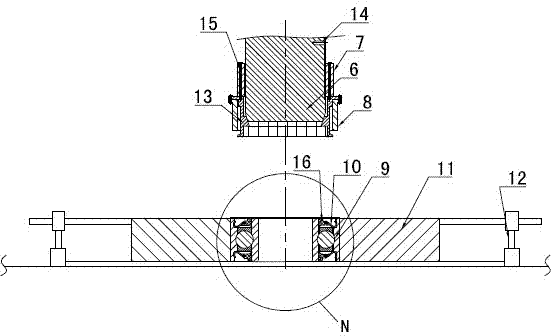

[0019] Figure 1~3 It is the best embodiment of the stamping sealing device of the composite sealed bearing, and the following is combined with the attached Figure 1~3 The stamping sealing device of the composite sealed bearing is further explained.

[0020] Refer to attached figure 1 , The composite sealed bearing stamping sealing device includes a press 1, and the press 1 adopts a small air press. A stamping device 3 is fixedly installed under the piston punch rod 2 of the press 1, and a bearing fixed turning device 5 arranged vertically and coaxially with the punching device 3 is installed above the workbench 4 of the press 1. Bearing 9 to be assembled.

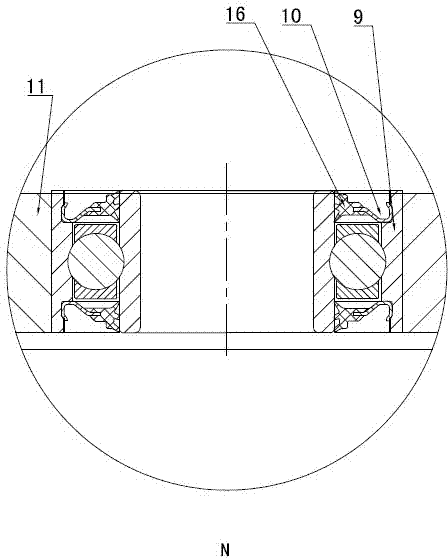

[0021] Refer to attached image 3 , the bearing 9 to be assembled is a composite sealed bearing, and its sealing structure is composed of a steel dust cover 10 on the outer ring and a rubber sealing ring 16 on the inner ring. The steel dust cover 10 is a deformable stamping assembly type dustproof Cover, steel dust c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com