Flexible crane wheel assembly line

A technology of cranes and assembly lines, which is applied in the direction of assembly machines, metal processing equipment, manufacturing tools, etc., can solve the problems of high labor intensity, difficulty in ensuring dimensional accuracy, wheel transfer and turning problems, etc., so as to save turning time and improve efficiency Advantages and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

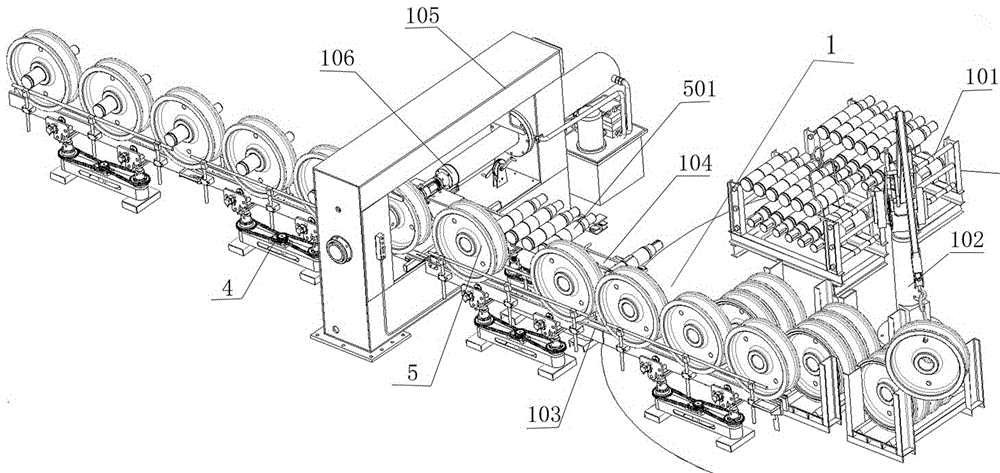

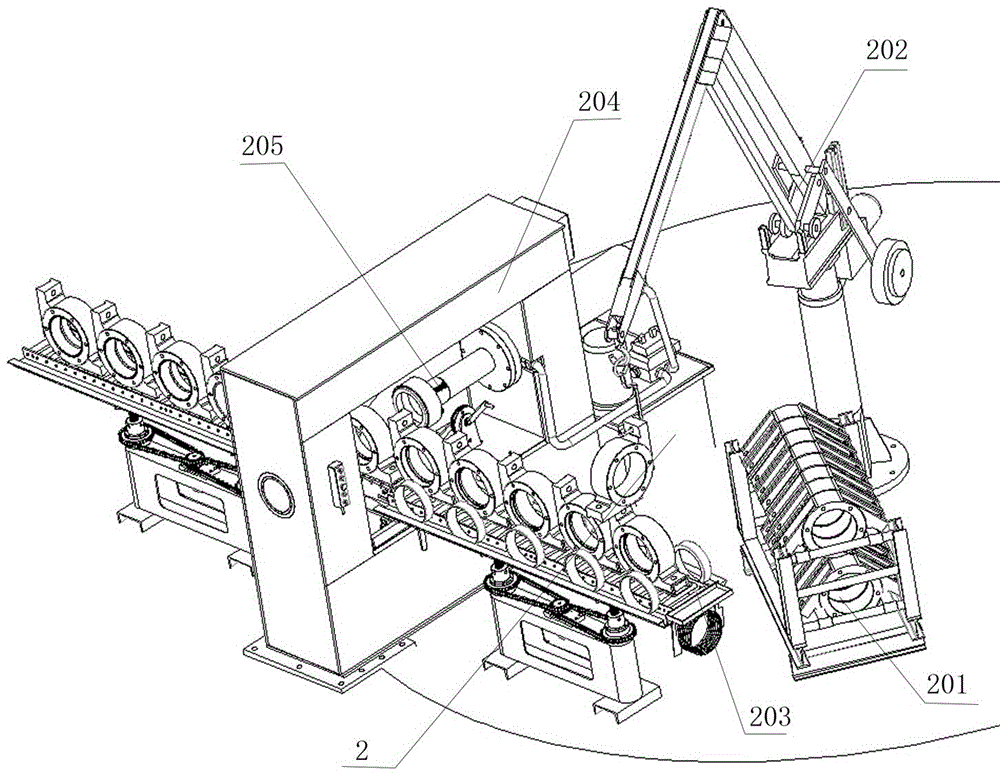

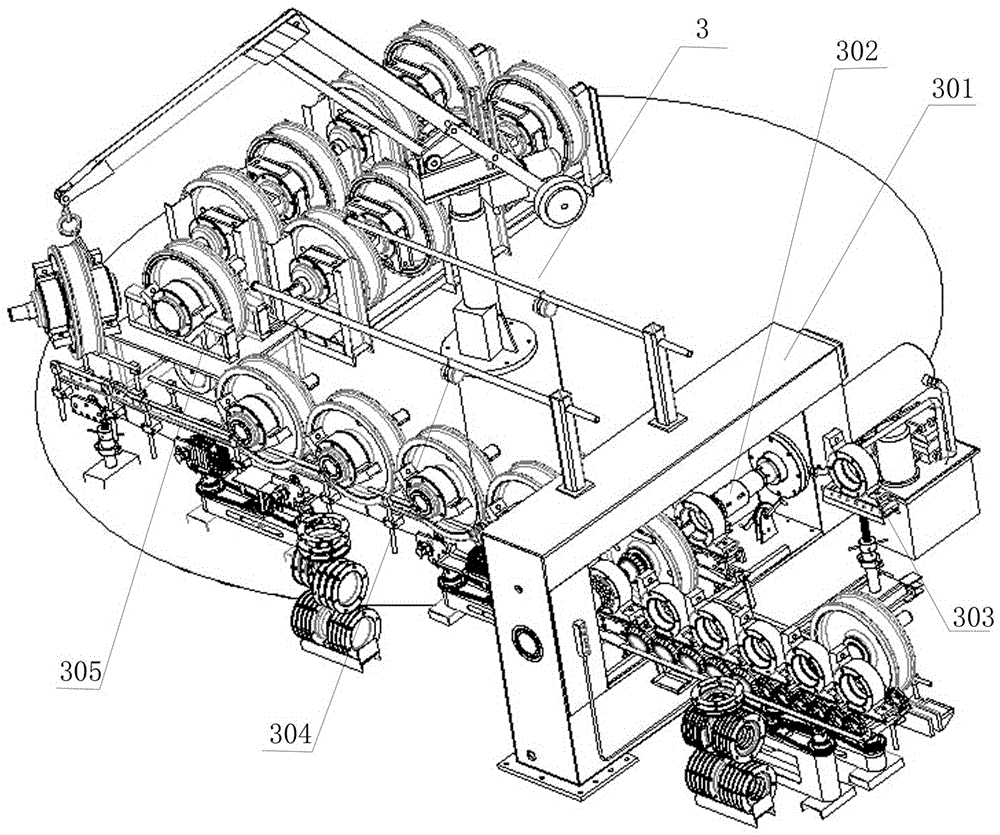

[0036] The first station area and the third station area form the main process with the wheel raceway as a straight line, and the second station area forms a sub-process with the corner box raceway as a straight line. The sub-process and the main process are parallel and organically combined. The gantry and corner box moving device transfers the finished corner box at the second station to the main process before the third station, and the three balance cranes are responsible for the loading or unloading of the parts of each station. The three stations are in the shape of "Pin", and the overall production line is in the shape of "Ju". The hoisting of workpieces in the overall production line can also be carried out in the form of a chain hoist, with three presses forming a three-dimensional production line.

[0037] As shown in the figure, the crane wheel flexible assembly line includes the first station area 1, the second station area 2 and the third station area 3. The first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com