Double-arm four-wheel polling robot mechanism

A technology of inspection robot and arm mechanism, which is applied in the field of mobile robots, can solve the problems of difficult application of ultra-high voltage transmission line inspection operations, limited ability to overcome obstacles, poor safety protection, etc., to achieve easy climbing of large-angle lines and reduce derailment Dangerous, walking ability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

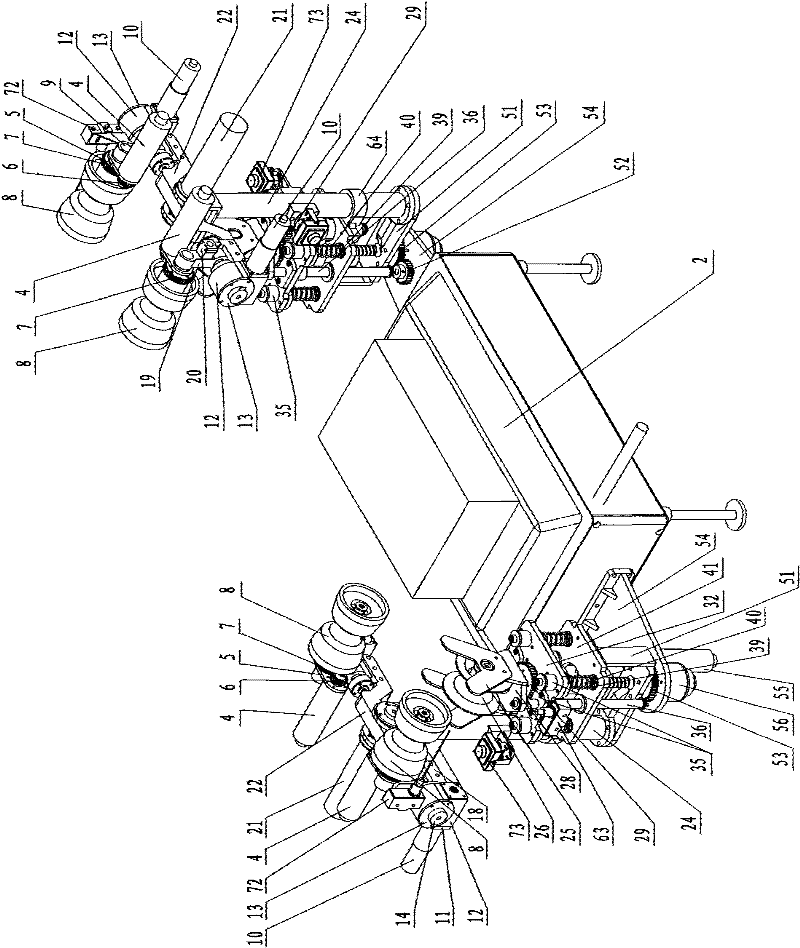

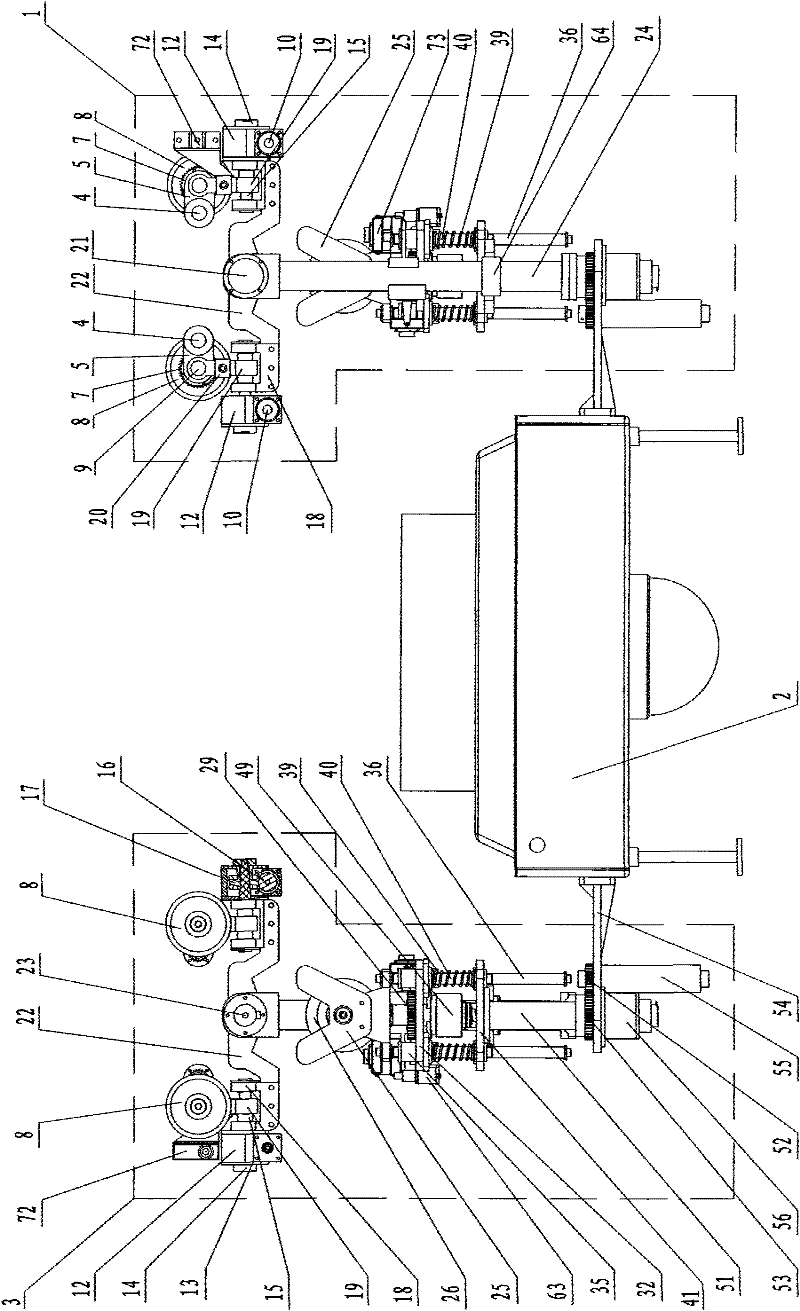

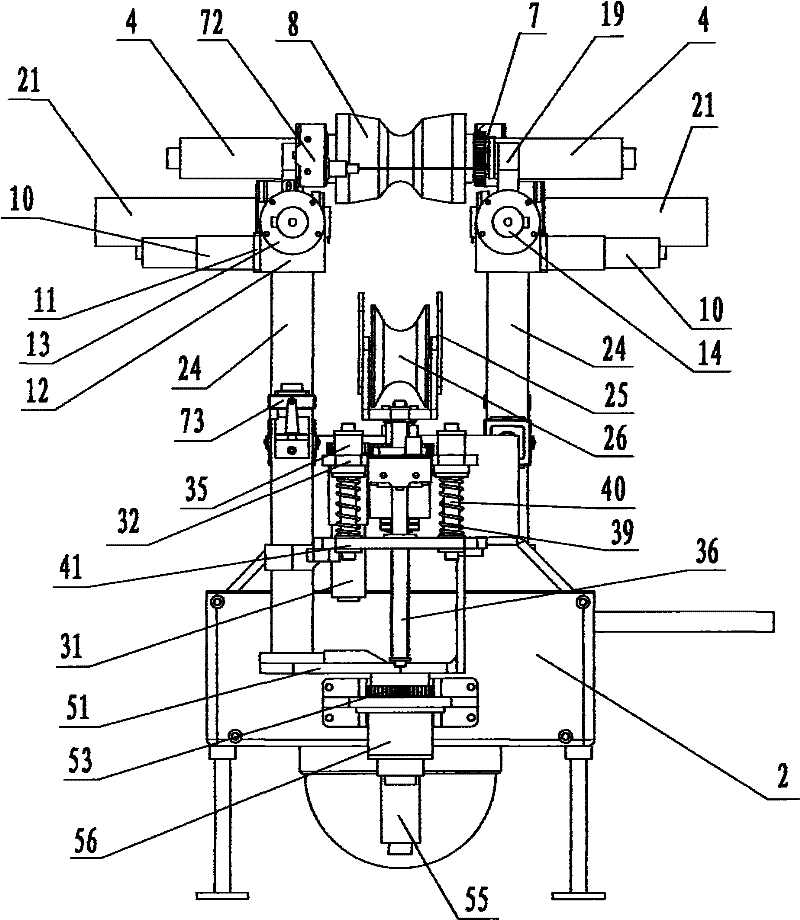

[0037] Embodiment 1 (the front and rear arm mechanisms are fixed symmetrically on both sides of the casing, and the distance between the two arm mechanisms is fixed.)

[0038] Such as Figure 1~3 As shown, the present invention is used for inspection operation on the overhead transmission line, including the front arm mechanism 1, the box body 2 and the rear arm mechanism 3, the front and rear arm structures 1 and 3 have the same structure, and are symmetrically installed on the box body 2 sides. Each arm mechanism includes two or more sets of walking mechanisms, a turning mechanism with the same number as the running mechanisms, a set of pitching mechanisms, one or more sets of clamping mechanisms and support arms 24, and the walking mechanisms of this embodiment are two groups, That is, the front traveling mechanism and the rear traveling mechanism, and the number of turning mechanisms are also two groups, that is, the front turning mechanism and the rear turning mechanism,...

Embodiment 2

[0060] Embodiment 2 (the distance between the front and rear arm mechanisms is adjustable through the transmission of the lead screw and the slider nut)

[0061] Such as Figure 15 As shown, the difference between this embodiment and Embodiment 1 is that the first and second motors 80, 83 are provided on the casing 2, and the output shafts of the two motors are respectively connected with the second and third motors installed on the casing 2. Leading screw 81,84, on the second and third leading screw 81,84, threadedly be connected with first, second slide block nut 82,85 respectively, front and rear arm mechanism 1,3 and second, one slide block nut 85, 82 is connected, the rotation of the second and first motors 83 and 80 is driven by the thread transmission of the third and second lead screws 84 and 81 and the second and first slider nuts 85 and 82 to drive the front and rear arm mechanisms 1 and 3 to reciprocate Move to adjust the distance between the two arm mechanisms. T...

Embodiment 3

[0062] Embodiment 3 (the distance between the front and rear arm mechanisms is adjustable through the transmission of the gear and the rack)

[0063] Such as Figure 16 As shown, the difference between this embodiment and Embodiment 1 is that: the casing 2 is provided with a third motor 89, the output shaft of the third motor 89 is connected with a gear 87, and the front and rear arm mechanisms 1, 3 are respectively connected There are first and second tooth racks 86,88 meshing with gear 87, and the first and second tooth racks 86,88 are set equally; the rotation of the third motor 89 is output by the gear 87 and the first and second tooth racks 86,88. The transmission drives the front and rear arm mechanisms 1 and 3 to reciprocate to adjust the distance between the two arm mechanisms. The third motor 89 works, the driving gear 87 rotates, and the gear 87 drives the first and second racks 86, 88 to move inward or outward through the engagement transmission with the first and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com