A civil aircraft jettison separation mechanism

A separation mechanism and civil aircraft technology, applied in the direction of ejection/detachment device, etc., can solve the problems of passenger aircraft body damage, fast speed, large explosion energy, etc., and achieve the effect of simple structure, small energy source, and limited damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

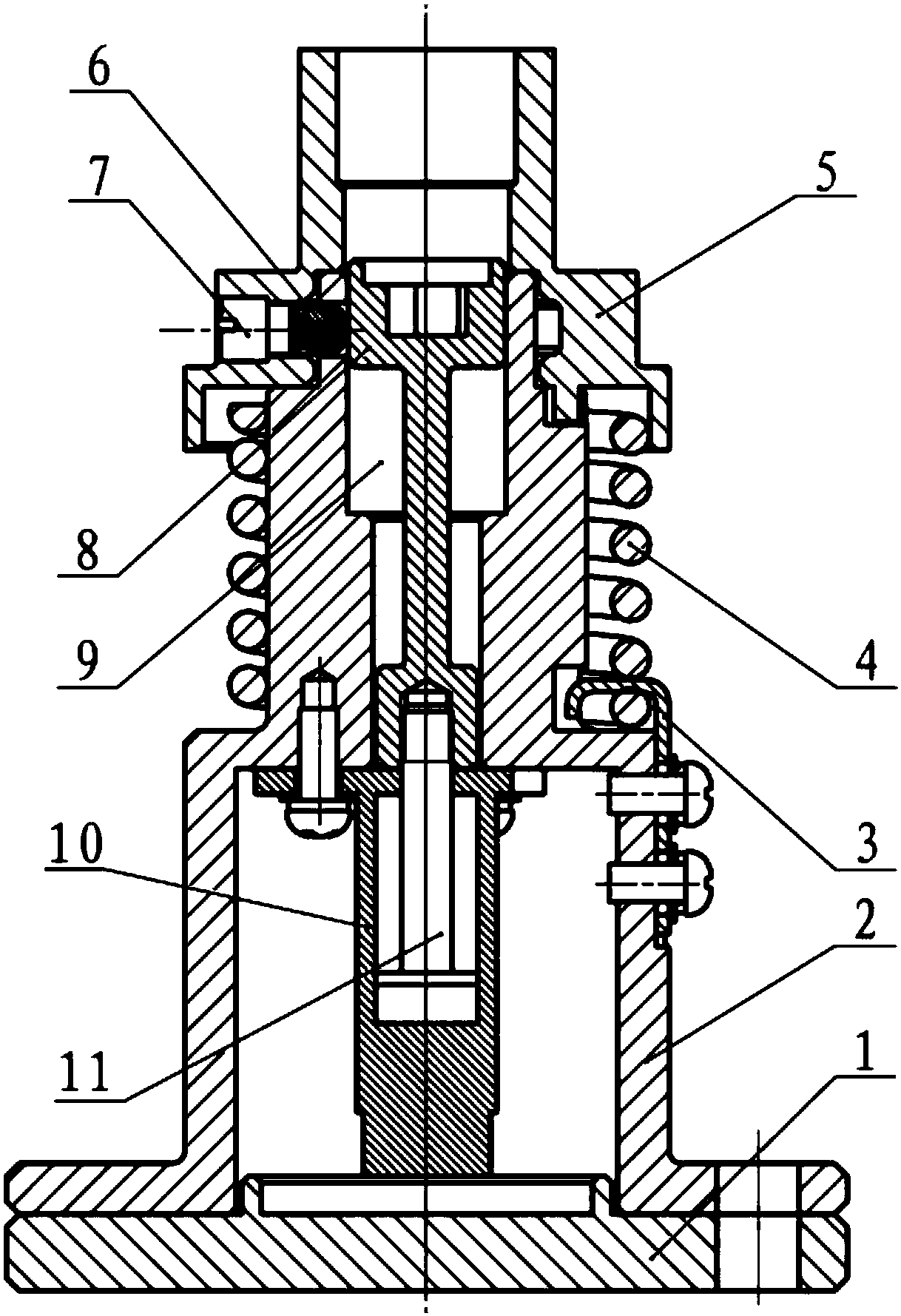

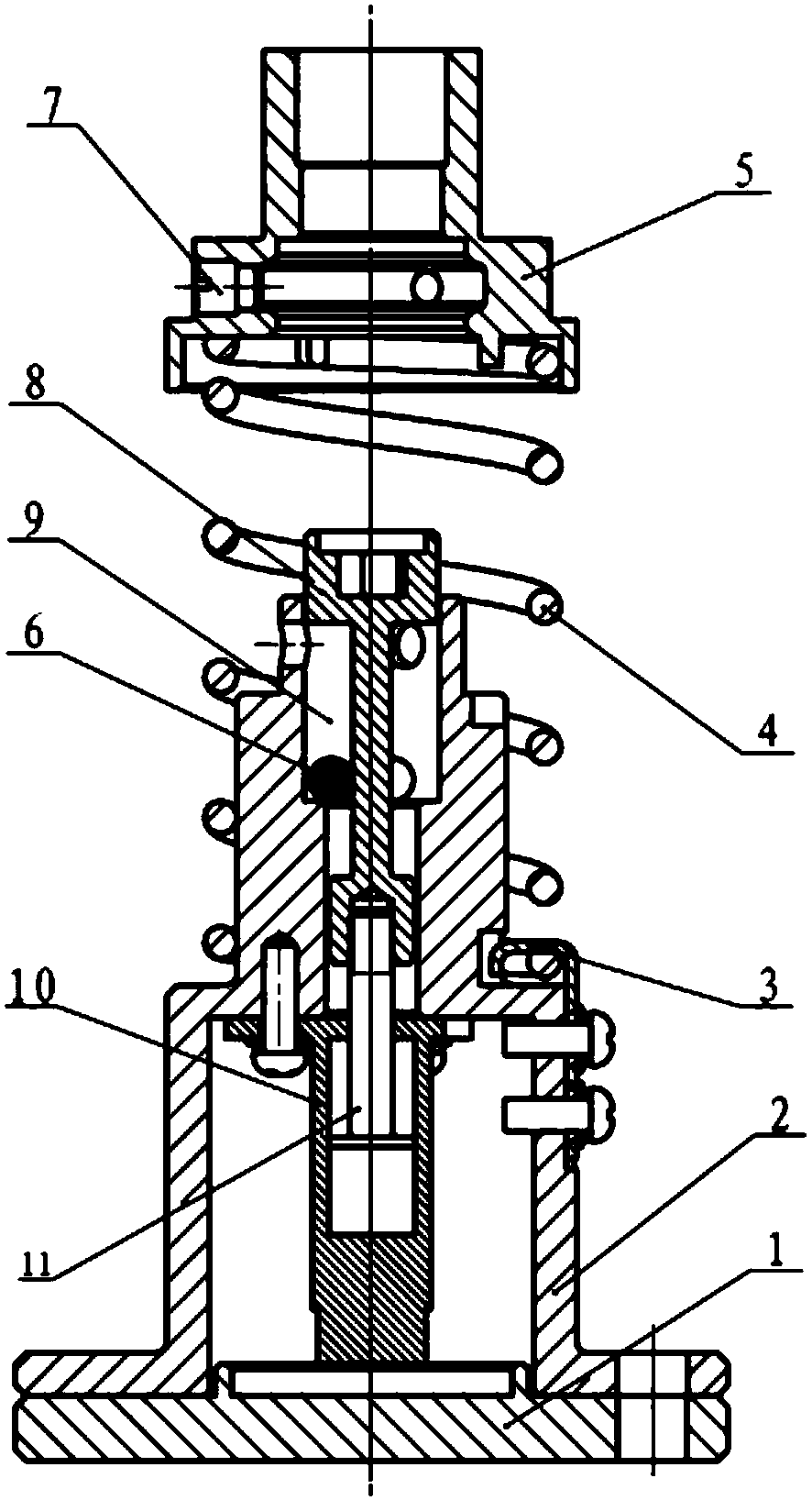

[0015] A civil aircraft jettison separation mechanism is used to separate the jettison recorder from the aircraft body before the civil plane crashes. The separation mechanism consists of a bottom cover 1, a base 2, a fixing clip 3, a compression spring 4, a connecting flange 5, Composed of steel ball 6, fixing screw 7, push shaft 8, steel ball drop groove 9 and driving part 10, the throwing type recorder is connected with the upper end of connecting flange 5; wherein

[0016] The base 2 is a cylindrical body with a stepped hole inside and has a number of radial holes distributed in the circumferential direction on the upper hole wall. The boss at the lower end and the bottom cover 1 are connected and fixed on the aircraft by screws. The driving part 10 Fixed in the cavity at the lower end of the base 2, the fixing clip 3 is fixed on the outside of the base 2, and the lower end of the compression spring 4 is clamped on the outside of the upper cylinder of the base 2; the push s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com