A fine-tuning angle device for balanced drilling pressure

A pressure-on-bit and angle technology, applied in rotary drilling rigs, drilling equipment and methods, construction, etc., can solve the problems of drill bit adjustment balance, uneven distribution of formation rock hardness, strong vibration of downhole drilling tools, etc., and achieve stable pressure output , Reduce downhole sticking and increase drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

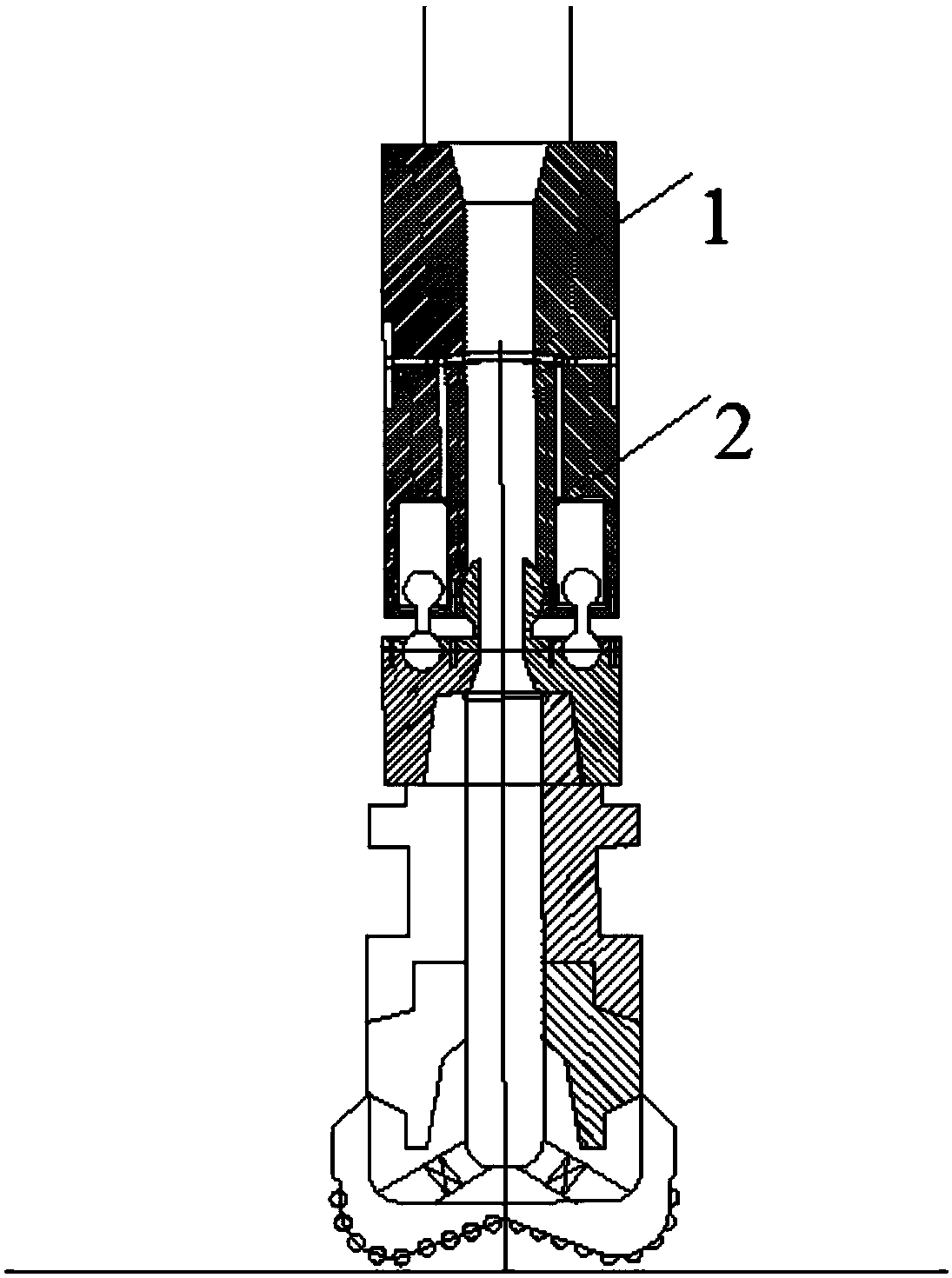

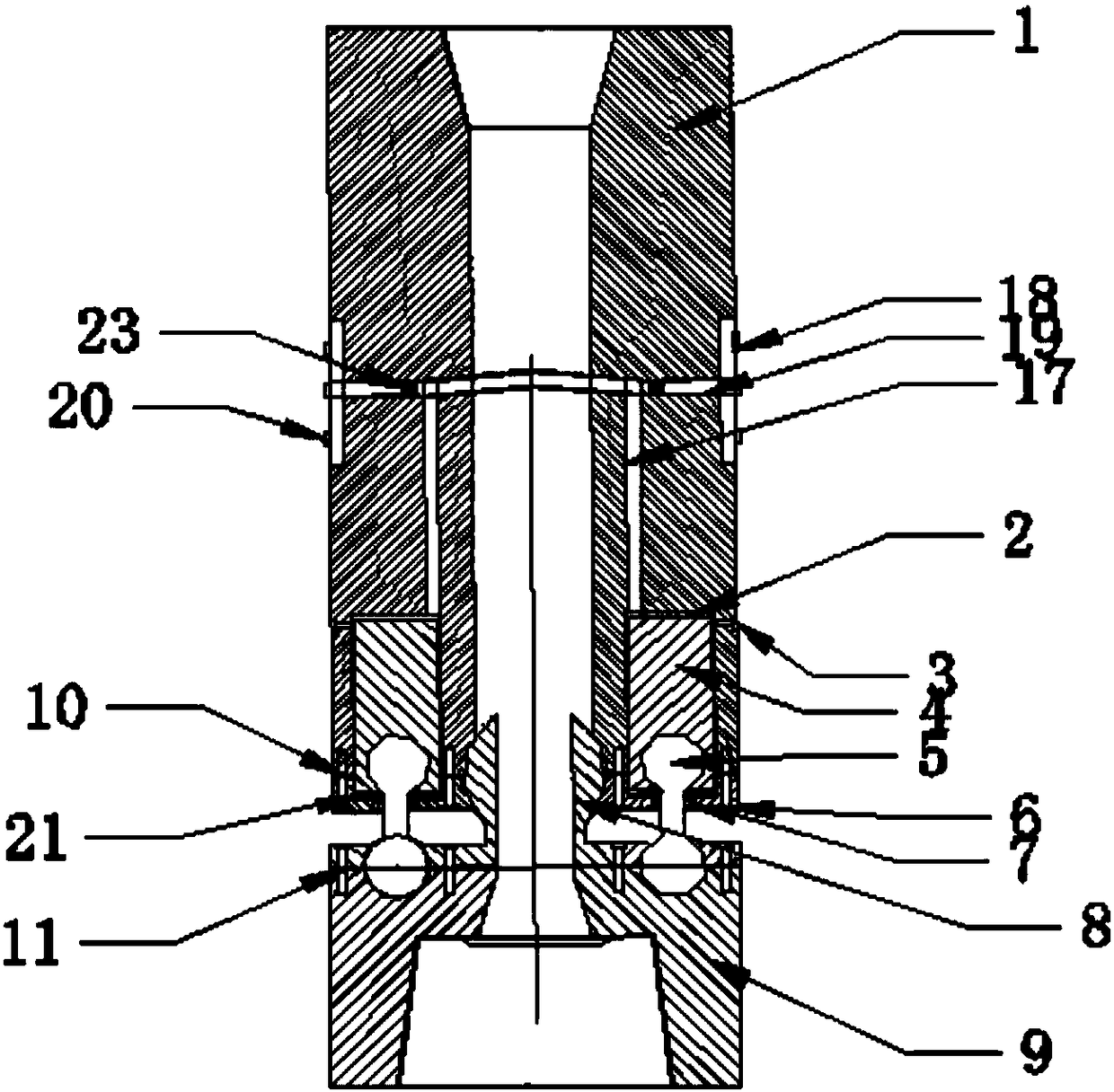

[0044] see Figure 1 to Figure 9 , a kind of weight-on-bit fine-tuning device provided in Embodiment 1, comprising:

[0045] The plurality of piston cavities 2 arranged inside the upper housing 1 are evenly distributed on the lower end surface of the upper housing 1, and the plurality of piston cavities 2 communicate with a plurality of hydraulic push columns 19 through communication channels 17, A plurality of piston cavities 2 are used to place the piston 4 and hydraulic oil, and each piston cavity 2 does not interfere with each other, and a plurality of first limit springs 23 are correspondingly welded between the plurality of push plates 18 and the plurality of hydraulic push columns 19;

[0046] The lower housing 6 connected to the upper housing 1 has a plurality of piston grooves inside the lower housing 6, and a plurality of hydraulic push columns 19 communicate with a plurality of pistons 4. The shape of the piston 4 is consistent with that of the piston cavity 2, and ...

Embodiment 2

[0070] see Figure 1 to Figure 11 , combined with the actual situation in the specific area, using a balanced weight-on-bit fine-tuning angle device in Embodiment 1, for specific description:

[0071] There are three sandstone formations in a certain block, and there are many formation interlayers, the formation dip angle is between 27° and 30°, the drillability of the rock is poor, and the formation is easy to deviate. The well depth is designed to be 4886m, the designed bottom hole inclination is less than 3°, and the maximum dogleg of the wellbore trajectory is less than 4° / 30m. Due to the lack of data on adjacent wells, when drilling to about 1500m and measuring the well inclination at a single point, it is found that the well The inclination of 1.2° is a bit too large, and the inclination is still increasing when drilling to 2000m. At this time, the drilling parameters are drill bit 311.15mm, drilling fluid density, 1.34g / cm 3 , the displacement is 28-30L / s, the standpip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com