Connector installation module for wall-hanging stove

A technology for installing modules and wall-hung boilers, which is used in household heating, lighting and heating equipment, and household heating, etc., can solve the problems of inconvenient operation, unsightly effects, and inconsistent installation during maintenance or replacement, and is conducive to aesthetics. The effect of avoiding instability, avoiding the limitation of installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, the present invention will be further described as follows:

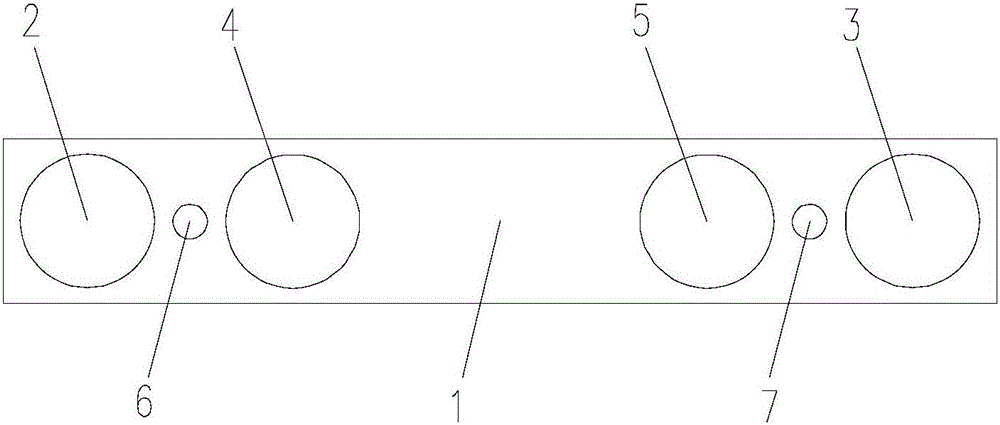

[0021] as attached figure 1 As shown, the present invention includes: module main part 1, heating pipe hole one 2, heating pipe hole two 3, domestic hot water outlet pipe hole 4, domestic hot water inlet pipe hole 5, wall fixing hole one 6 and wall fixing Hole two 7, module main part 1 is fixed on the wall surface through wall fixing hole one 6 and wall fixing hole two 7, heating pipe hole one 2, heating pipe hole two 3 are used to accurately fix and connect the heating pipe, life The hot water inlet pipe hole 5 is fixed and connected to the domestic hot water inlet pipe, and the domestic hot water outlet pipe hole 4 is fixed and connected to the domestic hot water outlet pipe.

[0022] Wherein, the module main part 1 is in the shape of a flat cuboid, and the first wall fixing hole 6 and the second wall fixing hole 7 are symmetrically arranged on the module mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com