Metal shell machining process and terminal

A technology of metal shell and processing technology, applied to the structure of telephones, etc., can solve the problems of long CNC processing time, scratches, and limit the price of mobile phones, so as to reduce the time of CNC processing and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

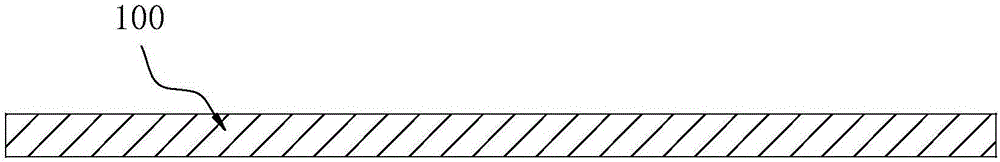

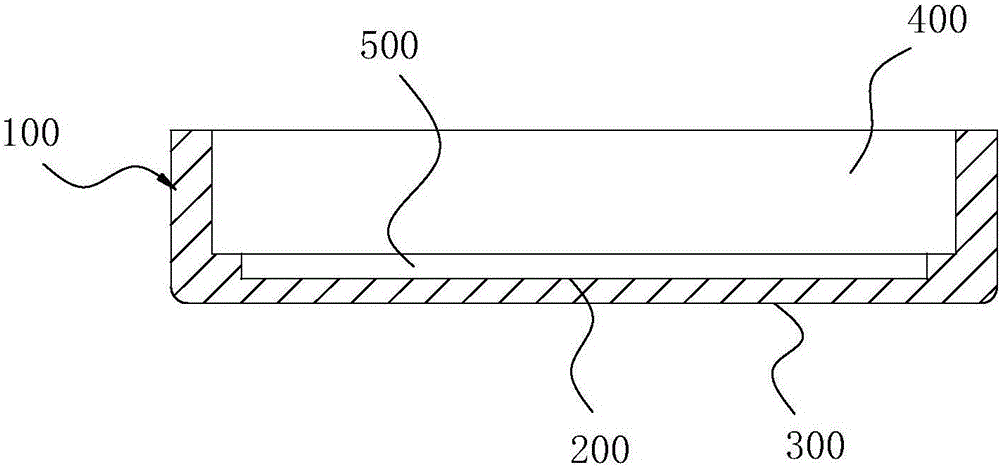

[0034] Such as figure 1 , 2 As shown, in this embodiment, a metal shell processing technology according to the present invention is characterized in that it includes the processing of the inner surface 200 and the processing of the appearance surface 300, and the processing of the inner surface 200 and the processing of the appearance surface 300 Both are processed by stamping, and the processing of the inner surface 200 and the processing of the exterior surface 300 are simultaneously formed by one stamping.

[0035] Compared with the traditional metal shell processing technology, the metal profile is used to perform CNC machining on both sides to form the required shell structure, which greatly reduces the time required for CNC machining and improves the processing efficiency. At the same time, compared with Double-sided CNC machining The material used to process the metal shell can be thinner, and less material needs to be removed during the process, which can save product...

Embodiment 2

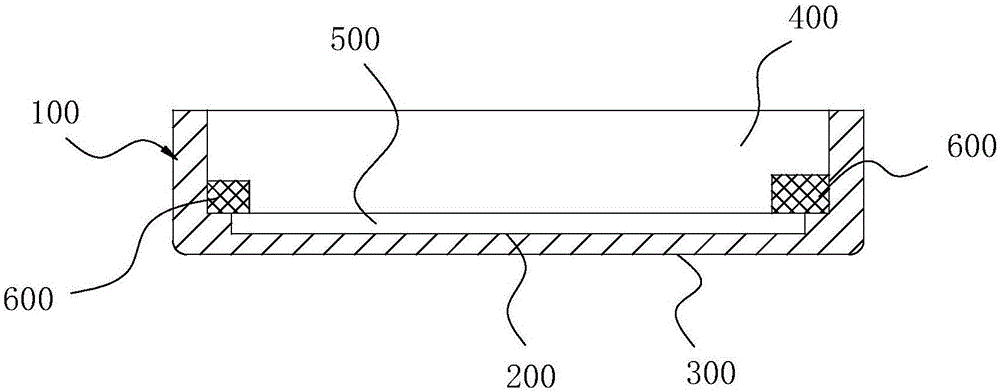

[0048] Such as Figures 1 to 4 As shown, in this embodiment, a metal shell processing technology according to the present invention is characterized in that it includes the processing of the inner surface 200 and the processing of the appearance surface 300, and the processing of the inner surface 200 and the processing of the appearance surface 300 Both are processed by stamping, and the processing of the inner surface 200 and the processing of the exterior surface 300 are simultaneously formed by one stamping.

[0049] Specifically, in this embodiment, the inner surface 200 is processed to form a storage cavity 400 for accommodating the internal components of the mobile phone by stamping on the inner surface 200 of the metal shell, and at the bottom of the storage cavity 400 toward the The accommodating groove 500 is recessed on one side of the appearance surface 300 . The appearance surface 300 is processed so that the appearance surface 300 forms a smooth surface as a pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com