Energy-saving and environment-friendly unfired light brick

An energy-saving, environmentally friendly, lightweight brick technology, applied in the field of non-fired lightweight bricks, can solve the problems of insufficient thermal insulation performance of the brick body, and achieve the effects of small structural strength and weather resistance, improved thermal insulation performance, and stable bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

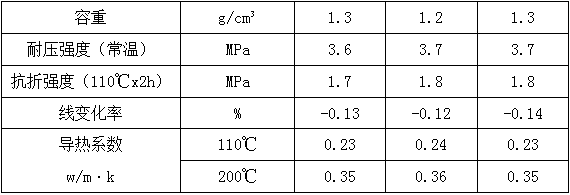

Embodiment 1

[0031] An energy-saving and environment-friendly fire-free lightweight brick. According to the mass parts, the raw material components of the lightweight brick include: 15 parts of cement, 20 parts of fly ash, 10 parts of energy storage aggregate, 10 parts of magnesium sulfate, and 10 parts of fine sand 3 parts of lime, 20 parts of water, 1 part of cement expansion agent.

[0032] In this embodiment, the preparation method of the energy storage aggregate includes the following steps:

[0033] (1) Add the multi-component organic phase-change mixture into a sealed reaction kettle, heat to 75°C until the material is liquefied, then add nano-alumina accounting for 6wt% of the multi-component organic phase-change mixture into the dispersion tank, and stir evenly until the material is evenly dispersed , then add 0.3wt% AlNSb quantum dots and 4.3wt% alkylphenol polyoxyethylene ether, and disperse at a high speed to obtain a mixed solution;

[0034] (2) Mix the mixed solution in the ...

Embodiment 2

[0047] An energy-saving and environment-friendly fire-free lightweight brick. According to the mass parts, the raw material components of the lightweight brick include: 20 parts of cement, 35 parts of fly ash, 20 parts of energy storage aggregate, 15 parts of magnesium sulfate, and 15 parts of fine sand 6 parts of lime, 25 parts of water, 2 parts of cement expansion agent.

[0048] In this embodiment, the preparation method of the energy storage aggregate includes the following steps:

[0049] (1) Add the multi-component organic phase-change mixture into a sealed reaction kettle, heat to 80°C until the material is liquefied, then add nano-alumina accounting for 8wt% of the multi-component organic phase-change mixture into the dispersion tank, and stir evenly until the material is evenly dispersed , then add 0.8wt% AlNSb quantum dots and 6.5wt% alkylphenol polyoxyethylene ether, and disperse at a high speed to obtain a mixed solution;

[0050] (2) Mix the mixed solution in the...

Embodiment 3

[0063] An energy-saving and environment-friendly fire-free lightweight brick. According to the mass parts, the raw material components of the lightweight brick include: 17 parts of cement, 28 parts of fly ash, 15 parts of energy storage aggregate, 12 parts of magnesium sulfate, and 13 parts of fine sand 4 parts of lime, 23 parts of water, 1.7 parts of cement expansion agent.

[0064] In this embodiment, the preparation method of the energy storage aggregate includes the following steps:

[0065] (1) Add the multi-component organic phase-change mixture into a sealed reaction kettle, heat it to 78°C until the material is liquefied, then add nano-alumina accounting for 7wt% of the multi-component organic phase-change mixture into the dispersion tank, and stir evenly until the material is evenly dispersed , then add 0.5wt% AlNSb quantum dots and 5.5wt% alkylphenol polyoxyethylene ether, and disperse at a high speed to obtain a mixed solution;

[0066] (2) Mix the mixed solution i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com