A three-screw self-cleaning natural circulation evaporator

A technology of automatic cleaning and natural circulation, applied in the field of automatic cleaning and convective heat transfer to strengthen energy saving, which can solve the problems of prolonged cycle, frequent periodic shutdown for cleaning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to illustrate the technical solution of the present invention more clearly, the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. Obviously, the following descriptions are only some embodiments of the present invention. In other words, other embodiments can also be obtained according to these embodiments without paying creative efforts.

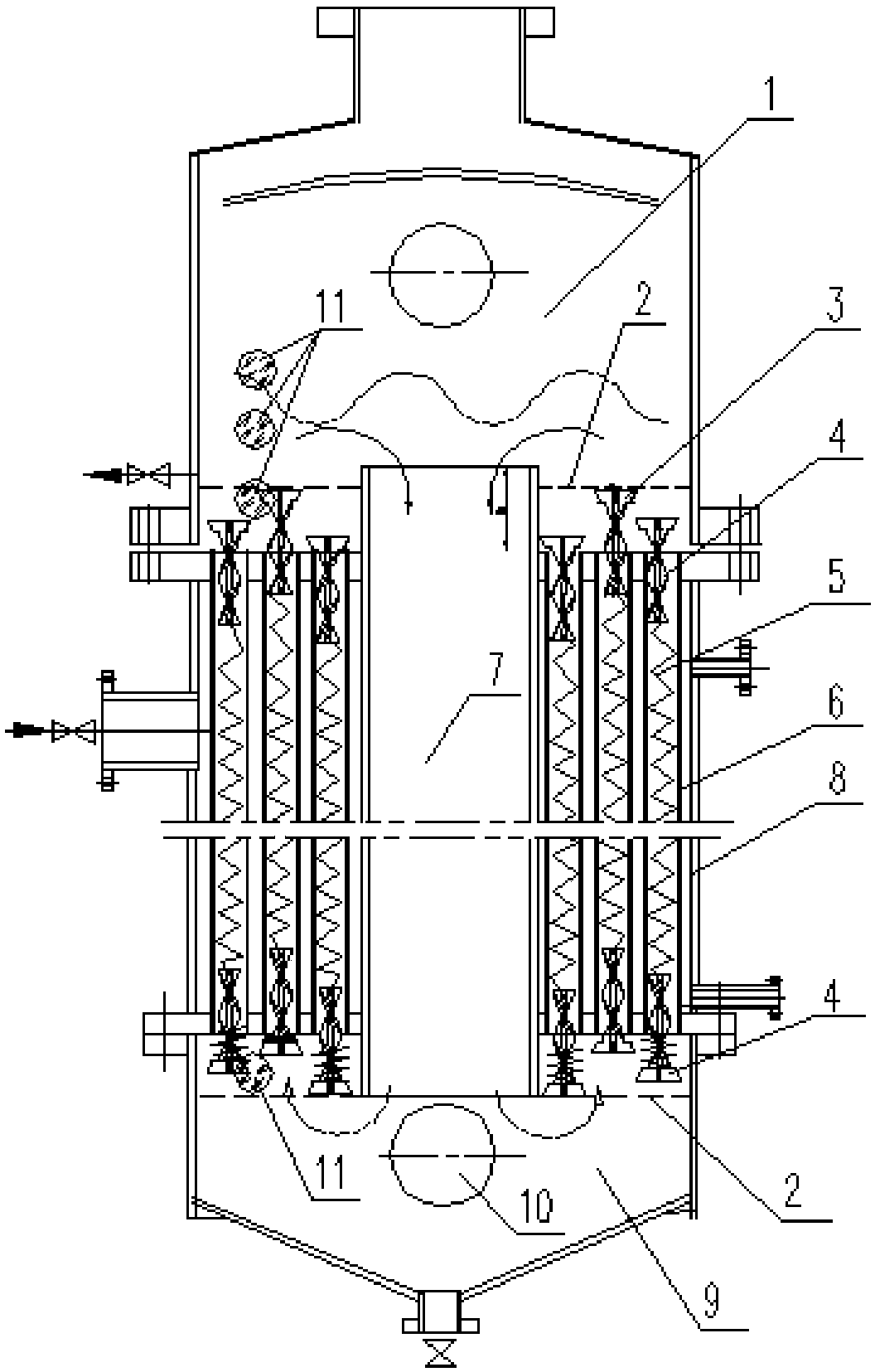

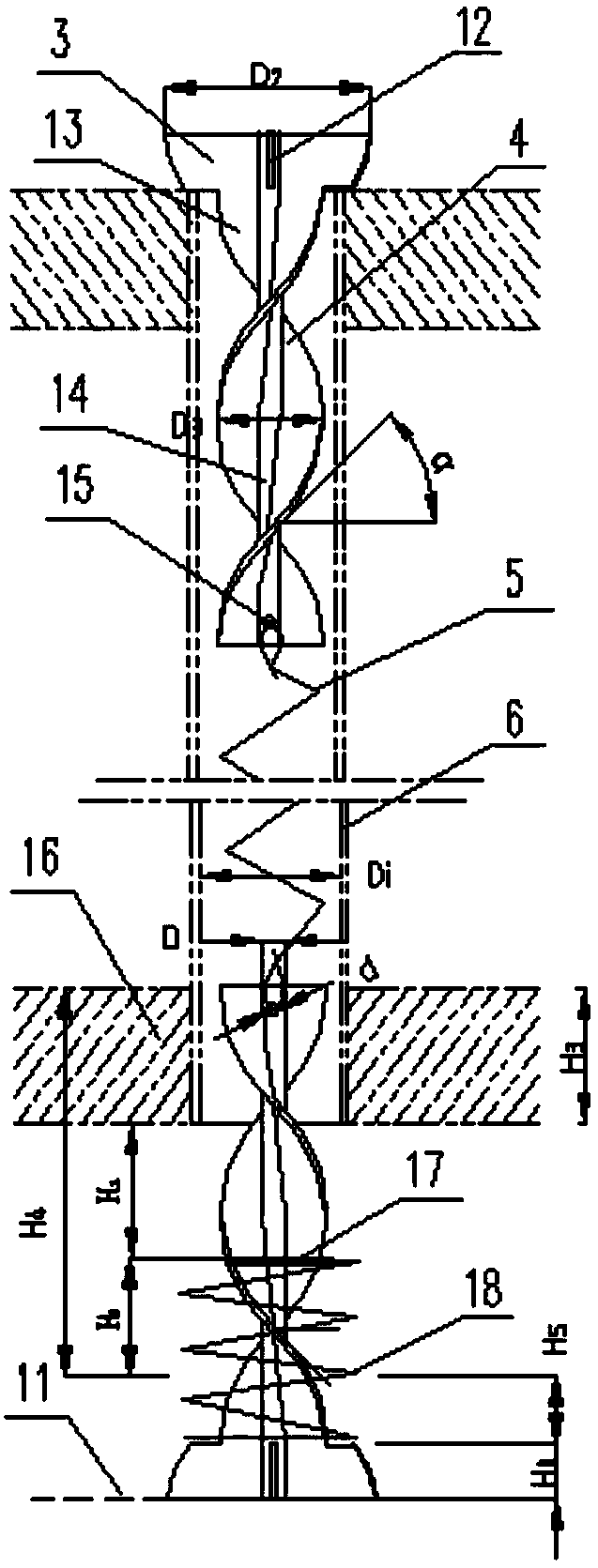

[0017] refer to figure 1 , figure 2 , a three-screw automatic cleaning natural circulation evaporator, the main components are an evaporation chamber 1, a three-screw mechanism 3, a heating pipe 6, a plastic spiral wheel 4, a cleaning screw 5, and a limit screen 2.

[0018] The three-screw mechanism 3 is an automatic cleaning mechanism for dirt in the heating pipe 6 of the natural circulation evaporator. The three-screw mechanism 3 is made up of a cleaning screw 5 and two plastic screw wheels 4 at both ends. The basic structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com