A multi-combination accelerated air purification laminar flow system and method thereof

An air purification and laminar flow technology, applied in the field of air purification, can solve problems such as affecting instruments or medicines, unable to be put into use quickly, and reduced dust concentration, so as to achieve rapid use and reduce the probability of entering the laminar flow hood. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

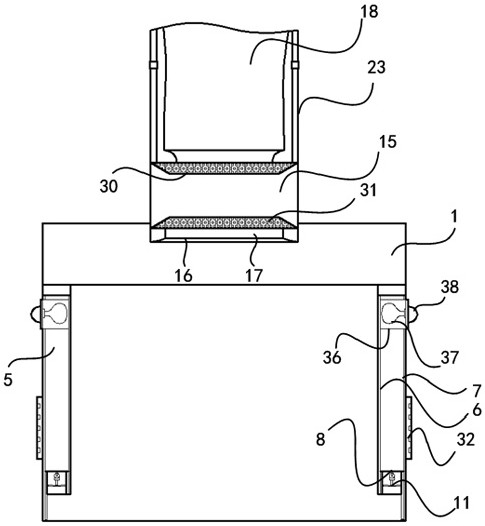

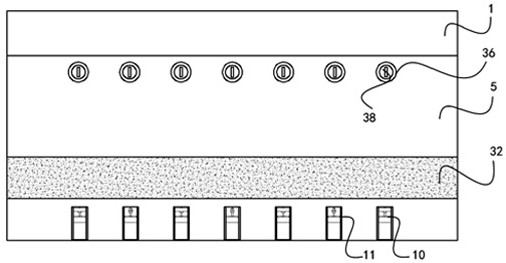

[0064] Such as Figure 1-9 As shown, this embodiment provides a multi-combination accelerated air purification laminar flow system, including a cover body 1, a detection mechanism, an air intake mechanism, a purification mechanism and a control mechanism.

[0065] The control mechanism includes: a processing module 2, which is used to generate work instructions for each component in the system and send the work instructions to the drive module 3; a drive module 3, which is connected to the processing module 2, and is used to receive the work instructions sent by the processing module 2 and drive Each component in the system operates according to a preset program; the storage module 4 is connected to the processing module 2 and is used to store the position information of each connection node in the clean room.

[0066] The cover body 1 includes a transparent blind 5, the blind 5 is arranged in a double-layer structure and is composed of an inner curtain 6 and an outer curtain ...

Embodiment 2

[0084] Such as Figure 1-9 As shown, the present embodiment provides a working method of multiple combined acceleration type air purification laminar flow system, including the following working steps:

[0085] S101: The counter 14 detects the air dust concentration at each connection node in the clean room and sends it to the processing module 2 .

[0086] S102: The processing module 2 extracts the serial number of the counter 14 with the largest sending concentration value and the position of the first air inlet 28 corresponding to the serial number.

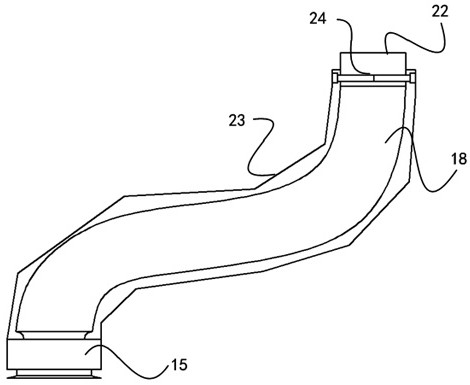

[0087] S103: The processing module 2 extracts the electric slider 27 closest to the second electro-hydraulic chuck 25, and generates an intermediate point between the electric slider 27 and the second electro-hydraulic chuck 25 on the track 26.

[0088] S104: The processing module 2 outputs a first sliding signal to the driving module 3, and the driving module 3 drives the electric slider 27 to slide to the middle point posit...

Embodiment 3

[0109] Such as figure 1 , 3 , 4, 5, 8, and 9, in this embodiment, the processing module 2 calculates the average value of the dust concentration at all connection nodes in real time, and when the dust concentration at the connection node is less than the average value, the processing module 2. Extract the number of the counter 14 with the largest sending concentration value at the current moment, and the position of the second air inlet 28 corresponding to the number; the processing module 2 outputs a disconnection signal to the drive module 3, and the drive module 3 drives the electric pipe frame 23 along the axis shorten until the first connection port 22 is separated from the second connection port 29 .

[0110] The processing module 2 outputs the fourth sliding signal to the driving module 3, and the driving module 3 drives the electric slider 27 to slide to the position of the second air inlet 28; the processing module 2 outputs the third connection signal to the driving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com