Deduster having fire-retarding and explosion-inhibiting functions and working method thereof

A working method and technology of a dust collector, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of electrostatic agglomeration and high dust concentration, achieve timely dust cleaning, low dust concentration, and prevent dust explosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

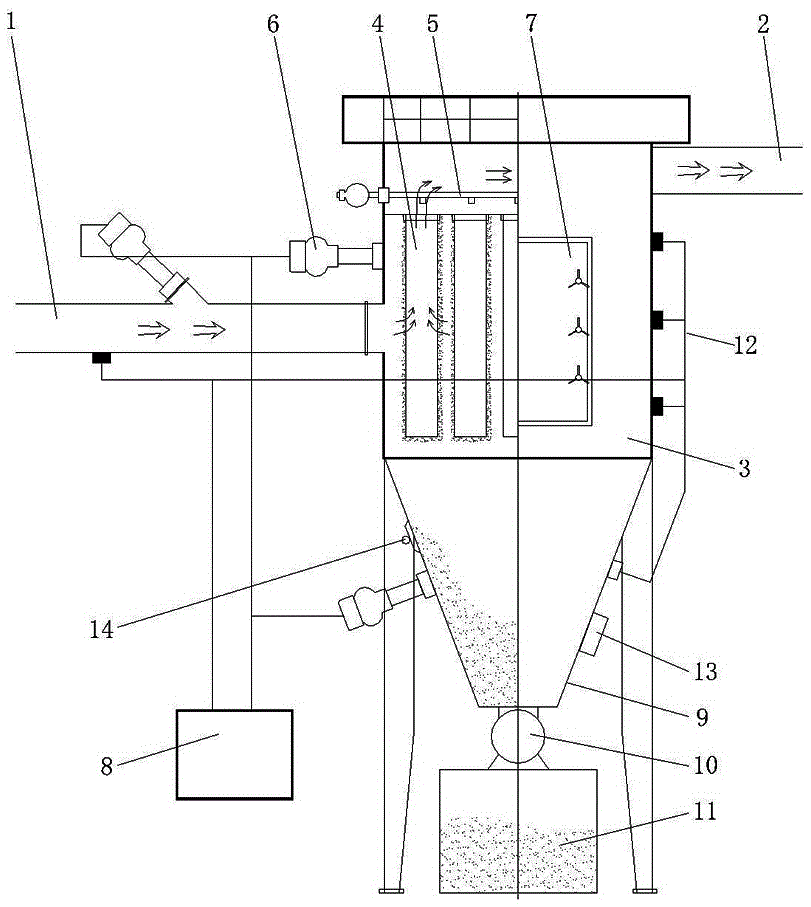

[0029] Such as figure 1 As shown, a dust collector with the function of fire arresting and explosion suppression in this embodiment includes: dusty gas inlet 1, purified gas outlet 2, box body 3, filter bag 4, pulse injection device 5, fire arresting and explosion suppression Device 6, explosion vent door 7, central control system 8, dust collection bin 9, unloader 10, ash hopper 11, composite fire sensor 12, vibrator 13 and level gauge 14.

[0030] The connection relationship of the above-mentioned components is as follows: the two sides of the box body 3 are respectively connected with a dust-laden gas inlet 1 and a purified gas outlet 2, and a plurality of filter bags 4 and a pulse injection device 5 are arranged inside; the box body 3 The bottom is connected with a dust collection bin 9, and the dust collection bin 9 is connected with the ash hopper 11 through the unloader 10; Explosion device 6 and composite fire sensor 12, described fire arresting and explosion suppress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com