Alarm method of linear composite thermal detector

A temperature-sensitive detector and line-type technology, applied in the direction of alarms, electric fire alarms, instruments, etc., can solve the problems of inability to realize the early fire warning function, inability to distinguish, and wrongly judge the output of fire alarm signals, etc., to achieve The effects of eliminating the confusion of short-circuit fire alarm signals and short-circuit fault signals, improving accuracy, and eliminating hidden dangers of false alarms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

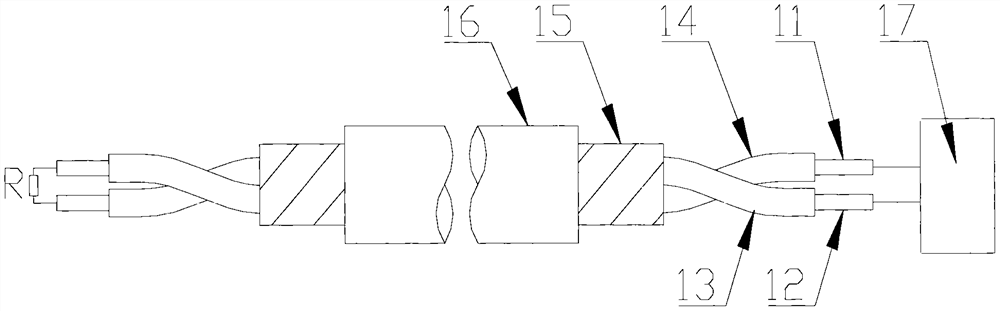

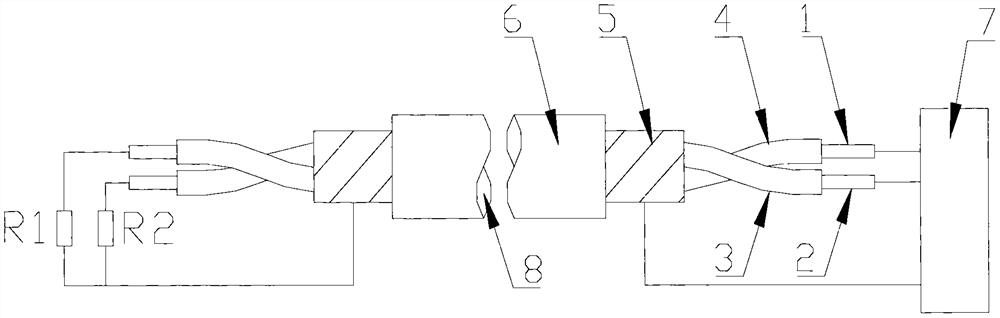

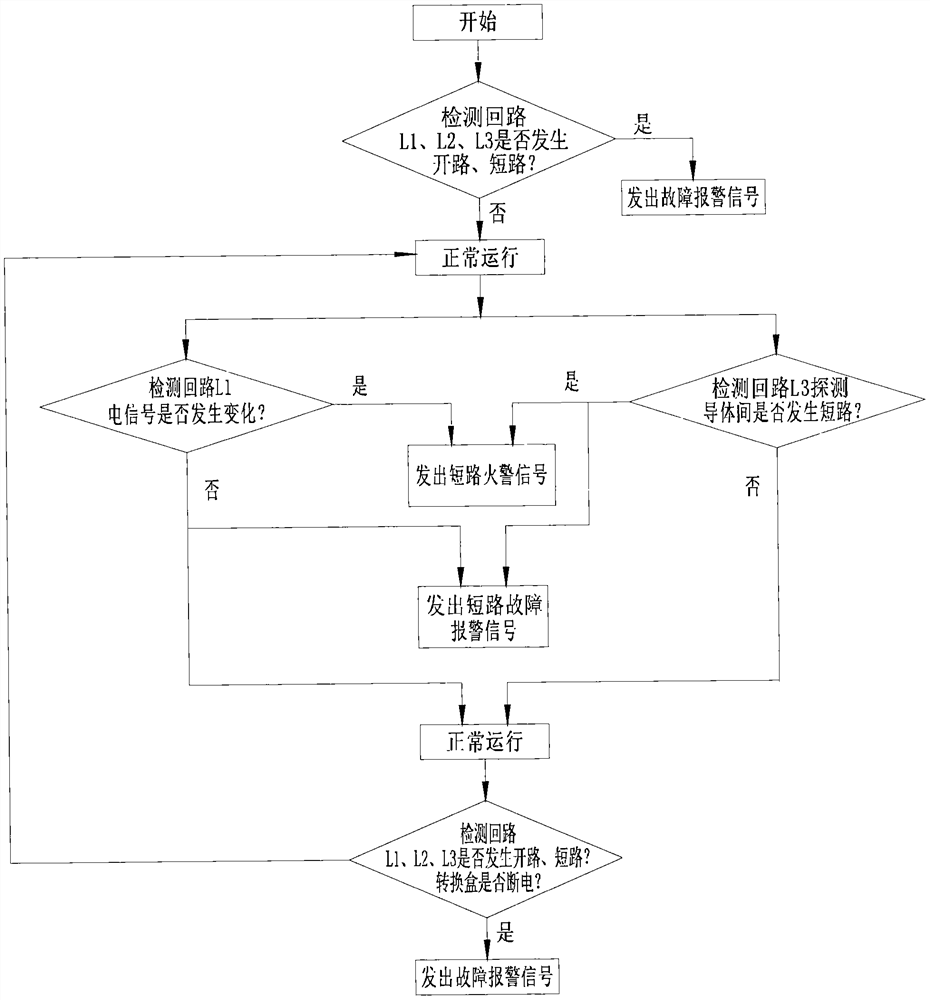

[0019] A kind of linear composite temperature-sensitive detector alarm method of the present invention, implementation sees figure 2 , image 3 : It is mainly composed of a conversion box 7, a detection cable 8, and terminal resistors R1 and R2. It is characterized in that the structure of the detection cable 8 is that a detection conductor 1 is coated with a plastic layer 4 with NTC characteristics, and another A detection conductor 2 is covered with a fusible insulating layer 3 , and two detection conductors 1 and 2 with the covering layer are intertwined with each other, and then the outer layer covers the third detection conductor 5 and the outer sheath layer 6 in turn. The detection conductor 1 and the third detection conductor 5 form a loop L1, the other detection conductor 2 and the third detection conductor 5 form a loop L2, and the detection conductor 1 and the other detection conductor 2 form a voltage difference loop L3.

[0020] Its working principle is: when the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com