Movable type elastic jacking device and manufacturing method thereof

A production method and a pop-up technology, which can be used in manufacturing tools, metal processing equipment, forming tools, etc., can solve problems such as waste, and achieve the effects of saving money, good versatility and reducing quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

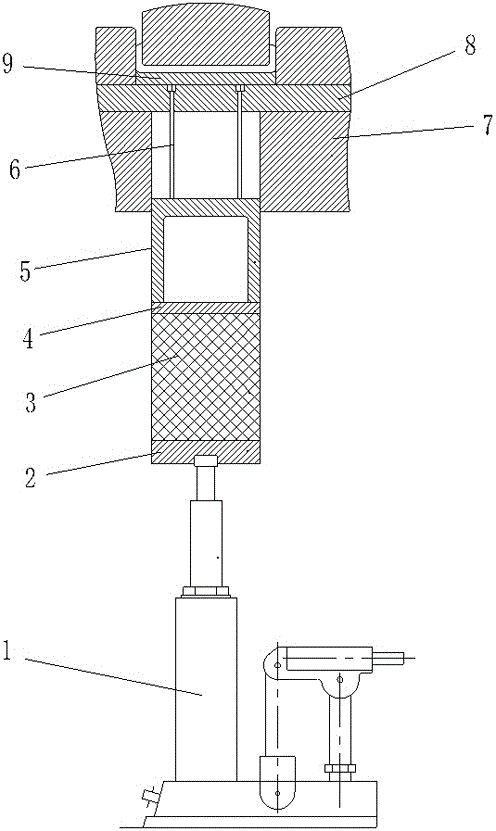

[0013] Embodiment one: if figure 1 As shown, a movable pop-up device includes a hydraulic jack 1, a lower backing plate 2 is screwed on the jack rod of the jack 1, and a rubber block 3 is arranged on the lower backing plate, and the rubber block The upper end of 3 is provided with an upper backing plate 4, and the upper backing plate is provided with a jacking block 5, and a locking bolt 6 is arranged on the jacking block.

[0014] In this embodiment, in order to reduce weight, the top block is a hollow top block.

[0015] Suppose there are 100 molds. Originally, each mold needs to be equipped with a pop-up device. Now, only about 10 are needed. This device can be moved, and the height and pressure of the ejector block can be adjusted through a jack. As long as the lower template 8 on the machine tool table 7 is provided with a through hole for bolts to pass through, the jack block jacks up the bolts, drives the top plate 9 to rise, and the workpiece is pushed out of the mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com