An early warning method for preventing the horizontal wheels of the main trolley of a ship unloader from falling off

A technology of horizontal wheel and ship unloader, which is applied in the direction of cranes, traveling bridge cranes, load suspension components, etc. It can solve the problems of horizontal wheel bearing damage, horizontal wheel falling off, rail gnawing, etc., and achieve the goal of avoiding secondary failures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

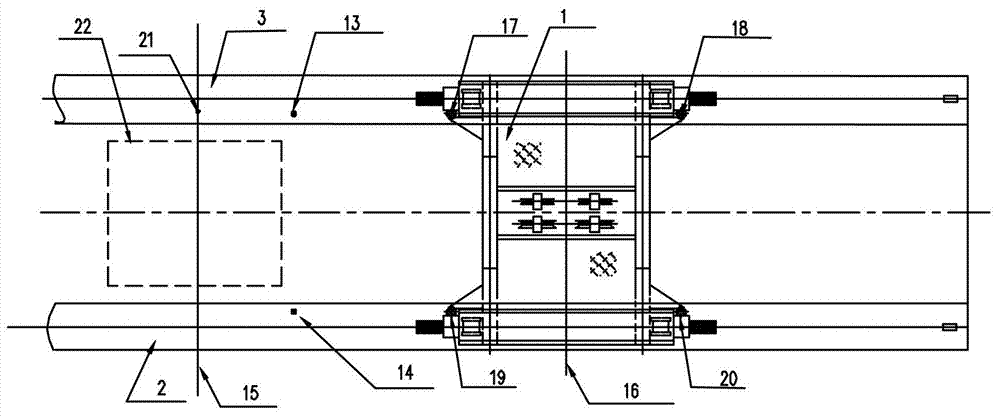

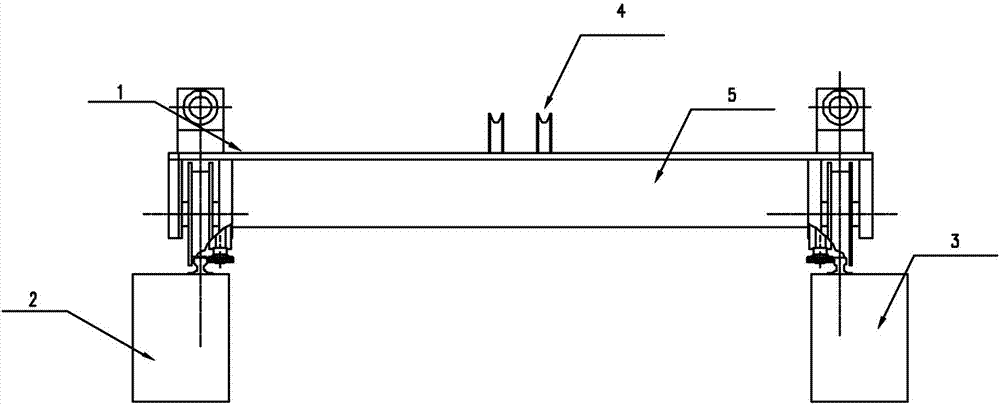

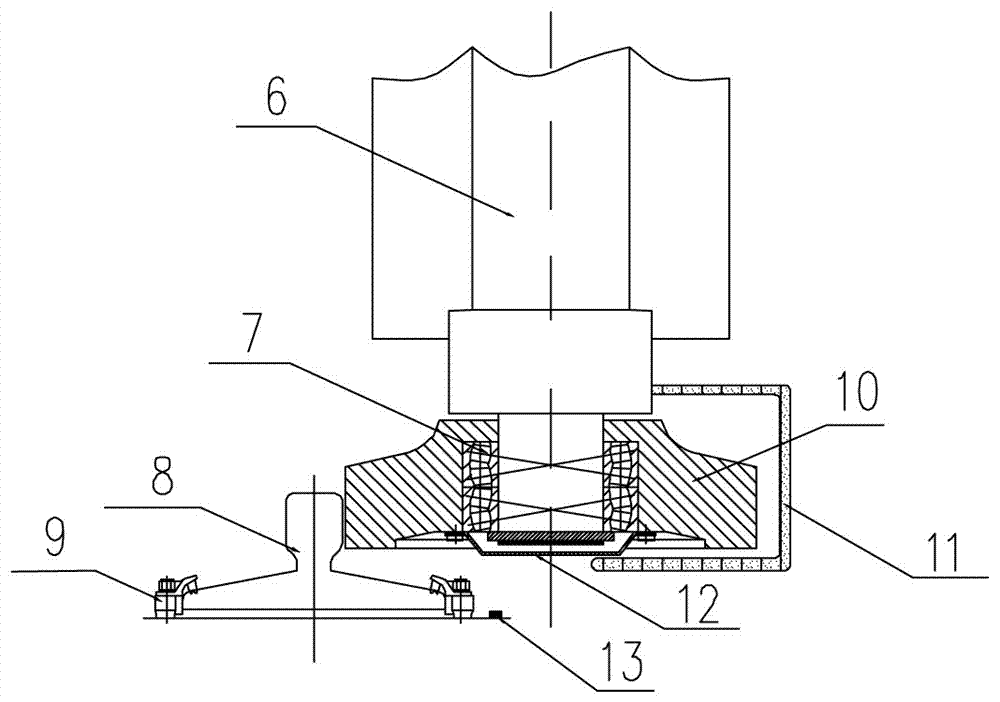

[0028] refer to figure 1 , 2 3. An anti-fall off warning system for the horizontal wheel of the main trolley of the ship unloader. The upstream rail beam proximity switch 13 and the downstream rail beam proximity switch 14 are symmetrically arranged on the bottom plate of the main trolley 1 double-track inner rail 8, and placed on the level of the main trolley. Just below the running track of the wheel 10, the signal output ends of the upstream track beam proximity switch 13 and the downstream track beam proximity switch 14 are connected to the ship unloader PLC system; a trolley is installed on the upstream track beam side of the main trolley zero-meter position line 15 The zero-meter position reference signal switch 21; the tail shaft of the main trolley motor is installed with an incremental encoder 23, the zero-meter position reference signal switch of the trolley and the signal output end of the incremental encoder are connected to the ship unloader PLC system, which is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com