Method for improving elastic deformability of lithium-based lubricating grease by using surface modified nanoparticles

A technology of surface modification of nanometer, lithium-based grease, applied in the field of grease, can solve the problems of declining lubricating performance, restricting the use of high-viscosity lubricating oil, etc., to achieve the effect of improving pumping capacity and changing elastic deformation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

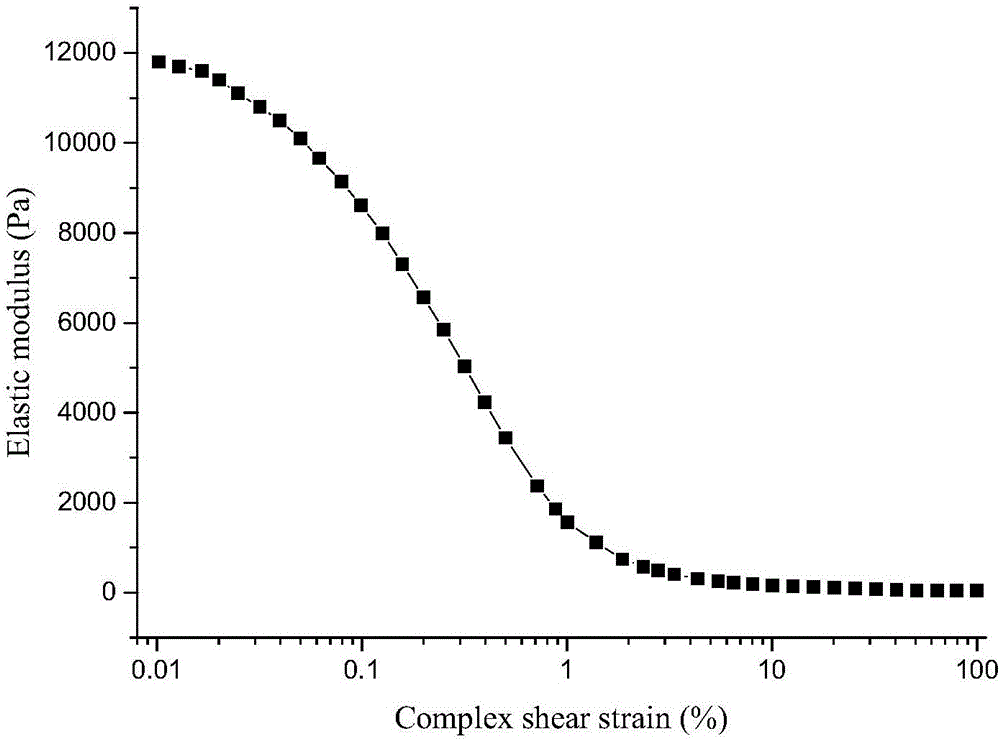

[0027] According to the parts by weight in Table 2, weigh the required amount of base oil polyalphaolefin, thickener 12-hydroxy lithium stearate, etc., heat and stir to 220°C, heat at constant temperature for 60 minutes, stop heating and cool at room temperature To 120°C, add 1 part of hydrophilic nano-alumina with a particle size of 10nm-30nm, stir and cool to room temperature, and grind three times with a three-roller machine. The types and amounts of each component in the grease are shown in Table 2. For embodiment 1 amplitude scanning modulus of elasticity result see figure 2 .

[0028] Table 2

[0029] Element parts by weight polyalphaolefin 87 Lithium 12-hydroxystearate 13 Hydrophilic Nano Alumina 1

Embodiment 2

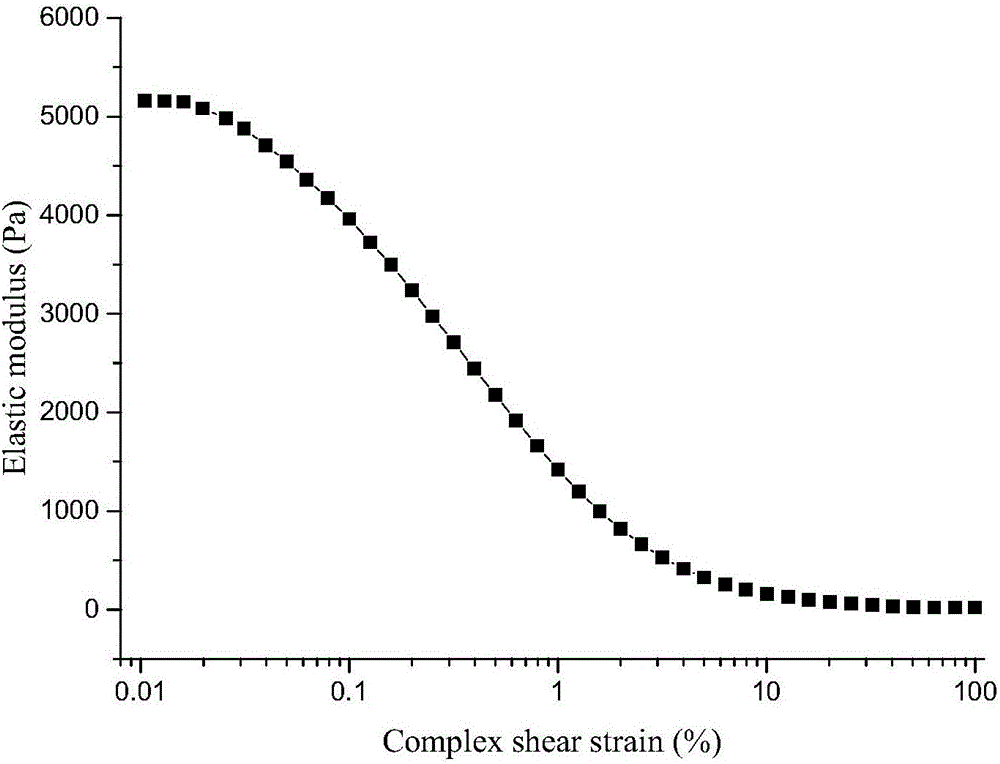

[0031] According to the parts by weight in Table 3, weigh the required amount of base oil, thickener, etc., heat and stir to 220°C, heat at a constant temperature for 60 minutes, stop heating and cool at room temperature to 90°C, add 1 part of lipophilic nano-oxidizer Aluminum, whose particle size is 10nm-30nm, is stirred and cooled to room temperature, and ground three times with a three-roll machine. See Table 3 for the types and amounts of each component in the grease. For embodiment 2 amplitude scanning modulus of elasticity result see image 3 .

[0032] table 3

[0033] Element parts by weight polyalphaolefin 87 Lithium 12-hydroxystearate 13 Oleophilic Nano Alumina 1

Embodiment 3

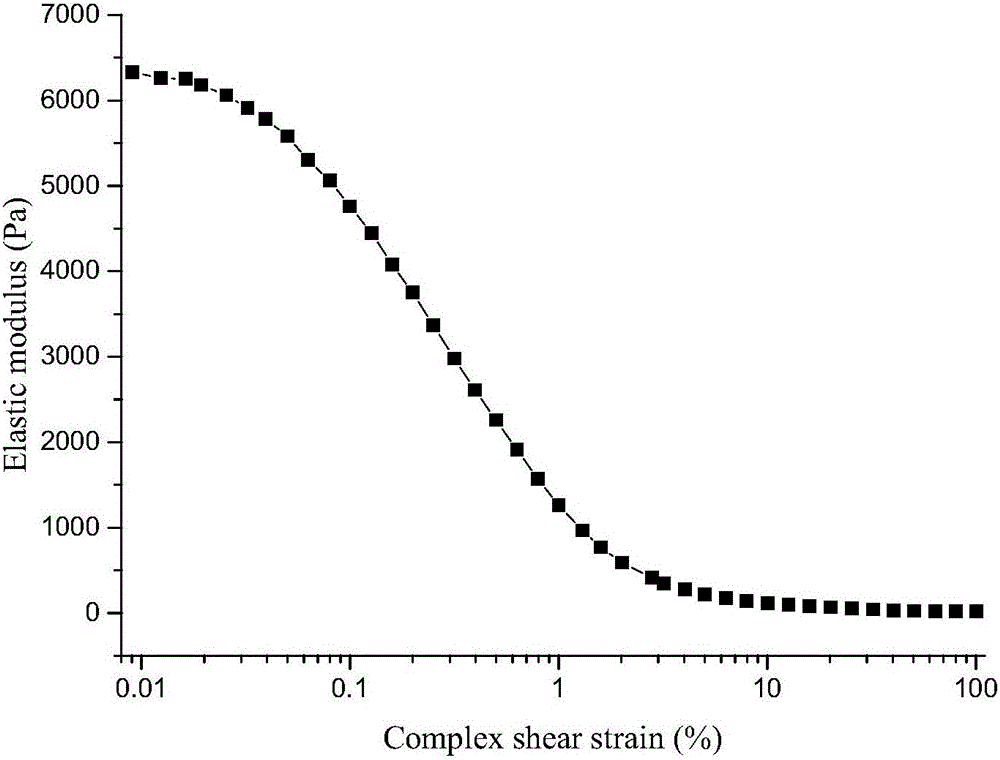

[0035] According to the parts by weight in Table 4, weigh the required amount of base oil, thickener, etc., heat and stir to 220°C, heat at a constant temperature for 60 minutes, stop heating and cool at room temperature to 90°C, add 5 parts of hydrophilic nano-oxidizer Aluminum, whose particle size is 10nm-30nm, is stirred and cooled to room temperature, and ground three times with a three-roll machine. See Table 4 for the types and amounts of each component in the grease. For embodiment 4 amplitude scanning modulus of elasticity result see Figure 4 .

[0036] Table 4

[0037] Element parts by weight polyalphaolefin 87 Lithium 12-hydroxystearate 13 Hydrophilic Nano Alumina 5

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap