Construction Technology of Fast-growing Poplar Modified by Carbon Fiber Outsourcing Steel Plate

A technology of outsourcing steel plate and construction technology, which is applied in the direction of wood processing appliances, wooden veneer joints, manufacturing tools, etc., and can solve problems such as low mechanical properties, poor corrosion resistance, and large instability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

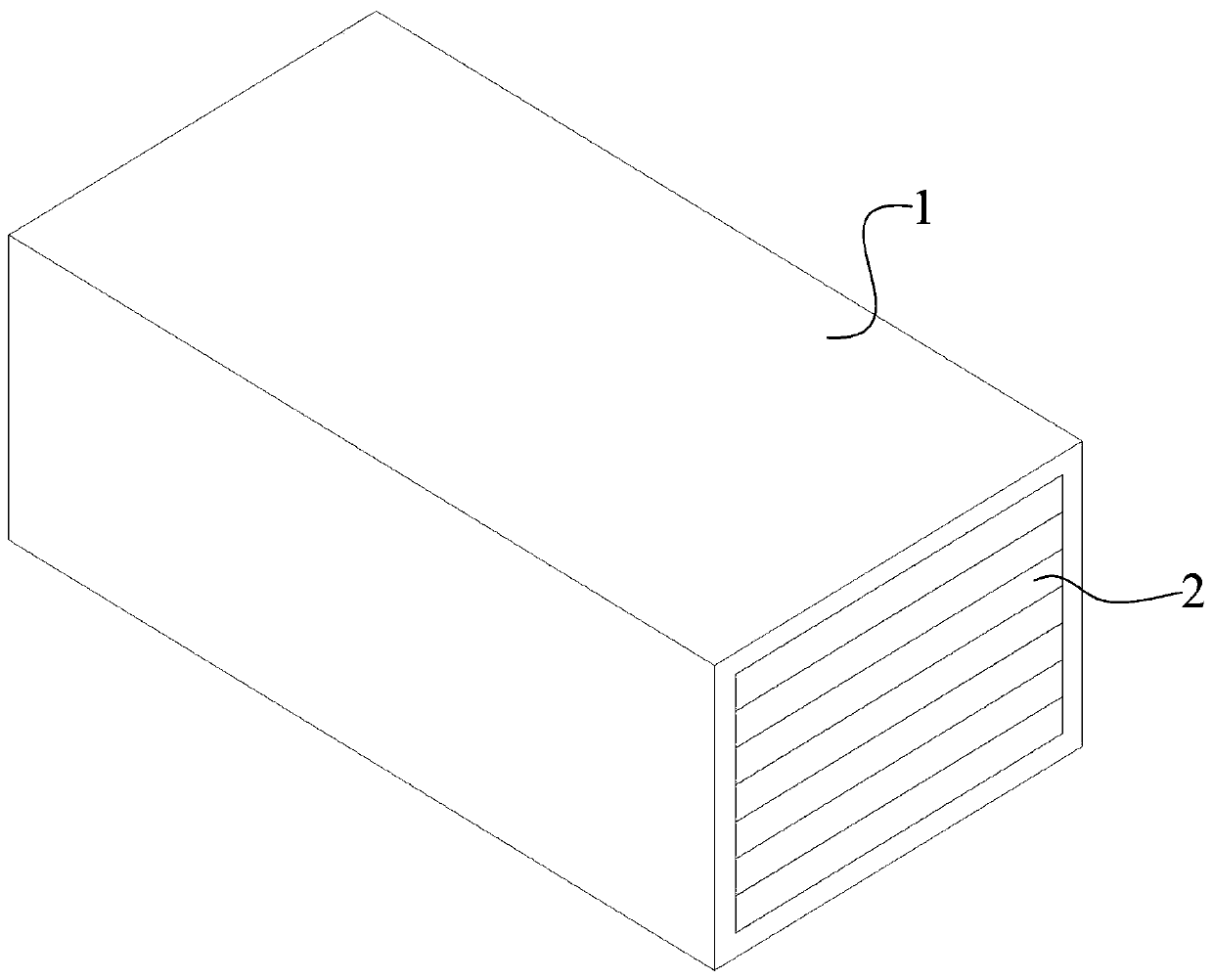

[0033] Example 1, such as figure 1 , figure 2 As shown, the present embodiment provides the construction technology of carbon fiber outsourcing steel plate modified fast-growing poplar

[0034] First of all, material selection, considering that the modified fast-growing poplar wood provided in this embodiment is used in construction, so in this embodiment, the selection of materials also plays a vital role in the strength of the finished product in the later stage. First, select The fast-growing poplar has a straight trunk and a log diameter of about 20cm, and put it in a cool place. The choice of poplar with a straight trunk is mainly because it is more convenient to process the poplar with a straight trunk. The log with a diameter of about 20cm is selected. Mainly considering the needs of the construction of this embodiment, the purpose of placing it in a cool place is mainly to avoid exposure to the sun, which will cause cracking of the poplar and affect its strength.

...

Embodiment 2

[0054] Embodiment 2, this embodiment provides a kind of construction technique of carbon fiber outsourcing steel plate modified fast-growing poplar

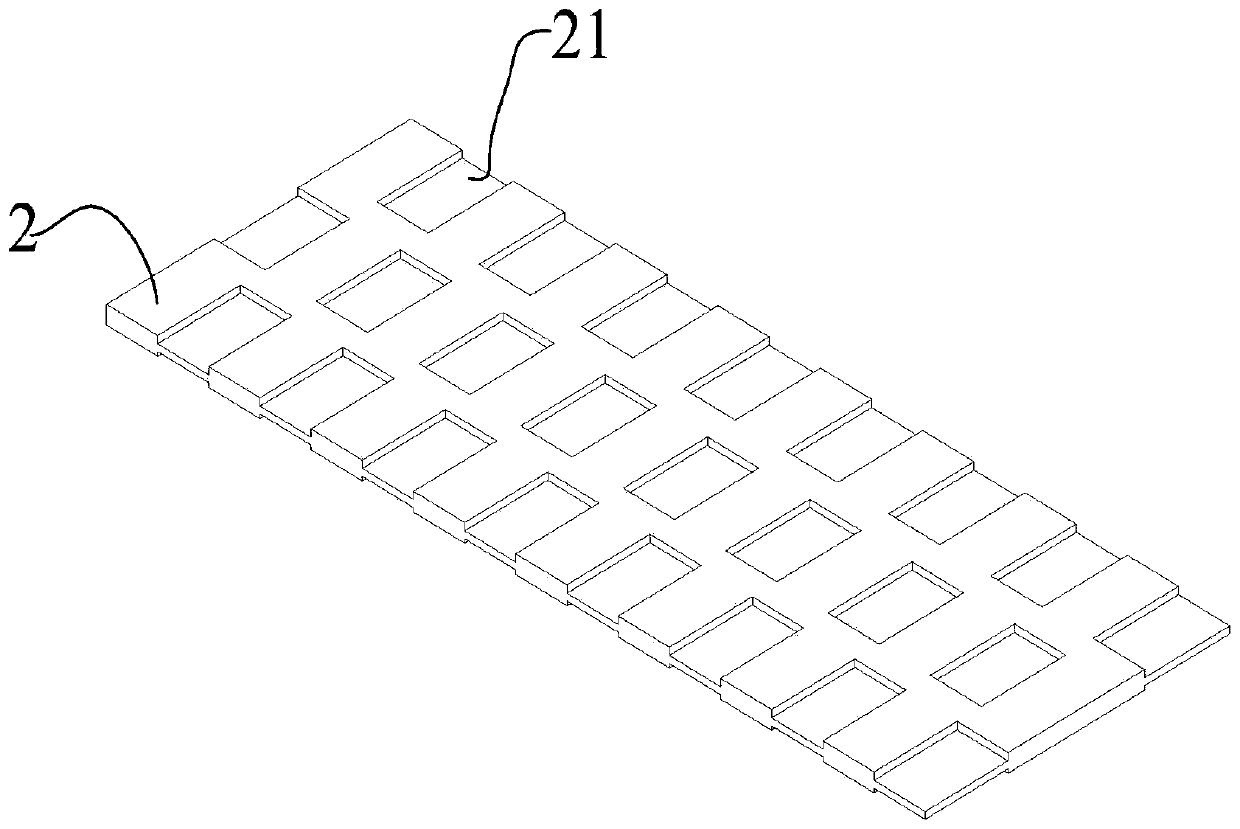

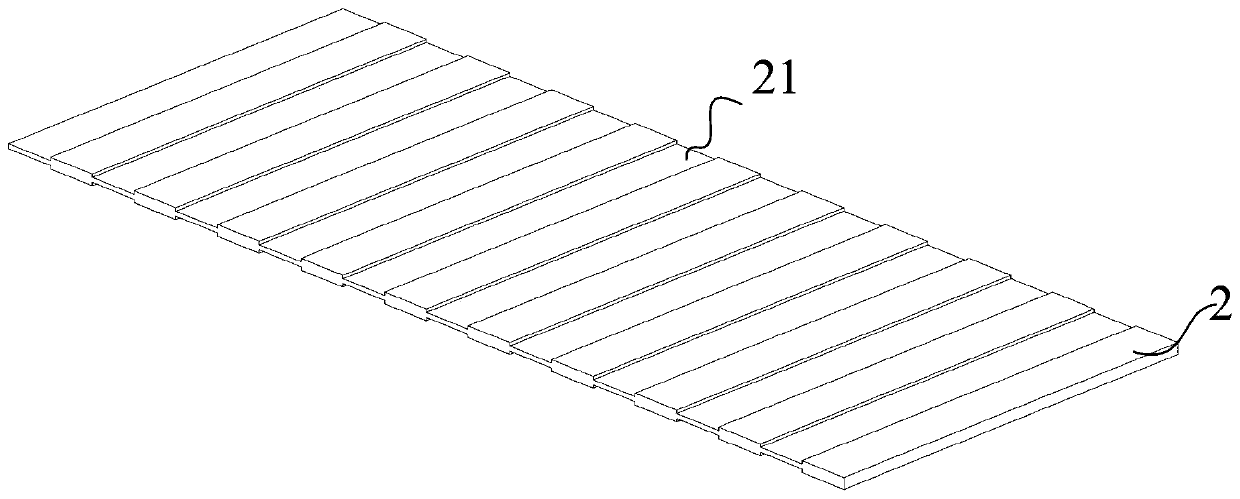

[0055] like image 3 As shown, the difference between the construction process of the carbon fiber outsourcing steel plate modified fast-growing poplar wood provided by this embodiment and embodiment 1 is the setting of the groove 21, compared with the groove provided by embodiment 1 along the long side of the poplar board The structure is arranged at intervals and staggered along the short side direction. The grooves 21 provided in this embodiment are set through the board 2, that is, the grooves 21 are only arranged at intervals along the long side direction of the poplar board 2. The benefits of this arrangement mainly lie in Convenient processing, because in the construction process, columns, beams, panels, walls of different sizes are required, the construction technology of the carbon fiber outsourcing steel plate modified ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com