Model similar material for simulating slope dangerous rock mass and preparation method of material

A technology of similar model and dangerous rock mass, applied in the field of slope dangerous rock simulation test, can solve the problems of unable to model cracks, unable to adjust bulk density, mechanical index, unable to meet the simulation of high slope dangerous rock mass, etc., to achieve easy mechanical properties Control, low cost, affordable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0054] A method for preparing a model-similar material for simulating a slope dangerous rock mass, comprising the following steps:

[0055] S1. Mix the barite powder and semi-refined paraffin evenly, then bake in an oven at 100°C for 3 hours, let the paraffin fully melt, soak into the barite powder, take it out and cool to room temperature;

[0056] S2, then add hydraulic oil and ultra-light clay to dry barite powder and semi-refined paraffin, mix evenly, and let stand for 2 hours;

[0057] S3. Finally, sieve the mixed materials to ensure that the paraffin, engine oil, ultra-light clay and barite powder are evenly mixed.

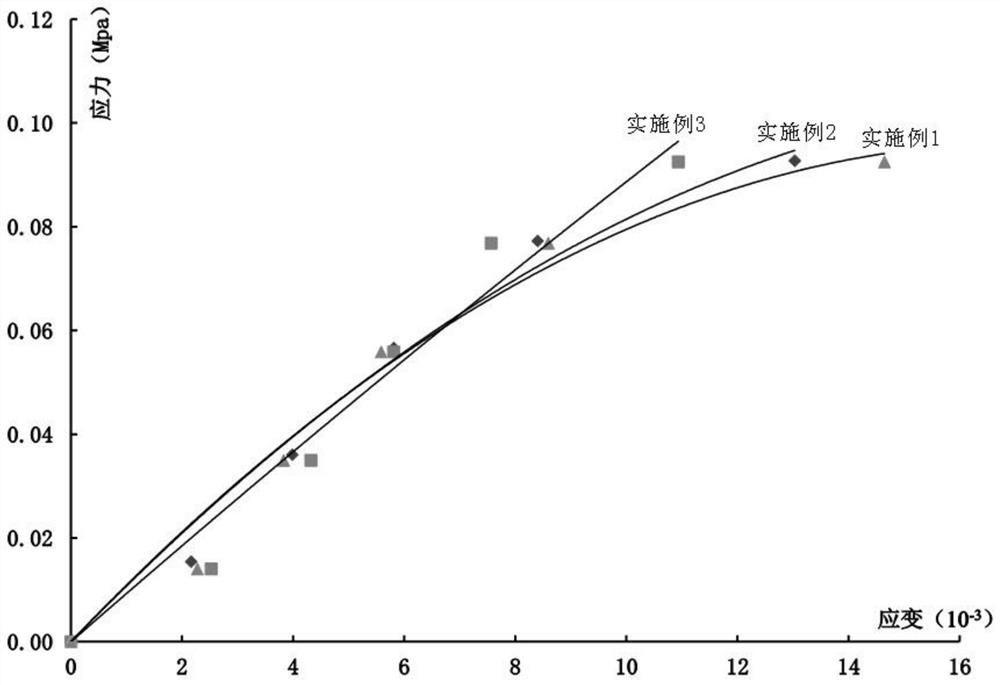

[0058] During the preparation process, the materials were weighed according to the size and bulk density of a single piece of similar material, and then put into the corresponding mold for compression molding, and then the mechanical properties were tested after a week of natural drying in the room. By selecting materials with different ratios, similar mate...

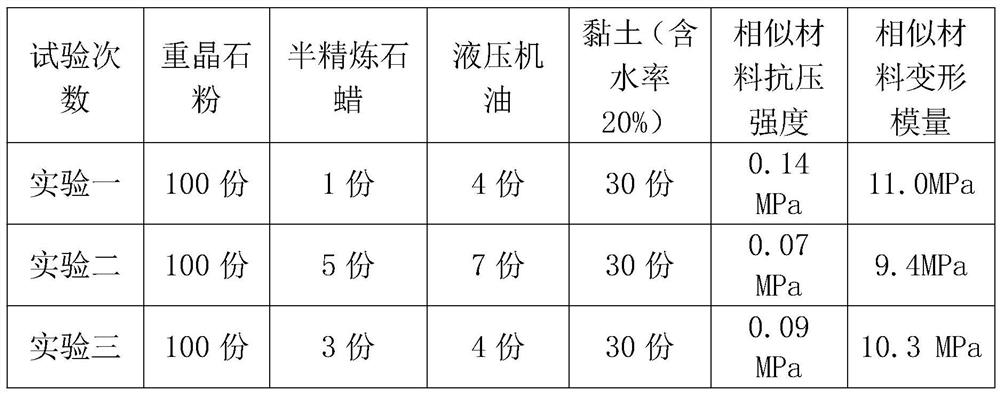

Embodiment 1

[0062] 100 parts of barite powder, 1 part of semi-refined paraffin, 4 parts of hydraulic engine oil, and 30 parts of ultra-light colored clay were made into a test piece with a bulk density of 18KN / m3 by the above preparation method, and then the mechanical performance test was carried out. The results showed that the prepared The compressive strength of the similar material of the dangerous rock mass is 0.14MPa, and the deformation modulus is 11.0MPa.

Embodiment 2

[0064] 100 parts of barite powder, 5 parts of semi-refined paraffin, 7 parts of hydraulic engine oil, and 30 parts of ultra-light colored clay were made into a test piece with a bulk density of 18KN / m3 by the above preparation method, and then the mechanical performance test was carried out. The results showed that the prepared The resulting dangerous rock mass has a compressive strength of 0.07MPa and a deformation modulus of 9.4MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com