Damping mechanism for bus duct special for wind power

A technology of vibration reduction mechanism and bus duct, which is applied in the direction of mechanical equipment, spring/shock absorber, vibration suppression adjustment, etc., can solve problems such as bus duct hazards, and achieve the effect of eliminating structural influence and eliminating position error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

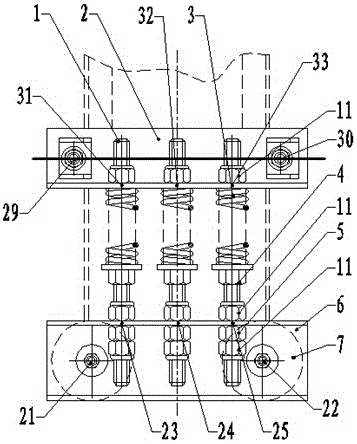

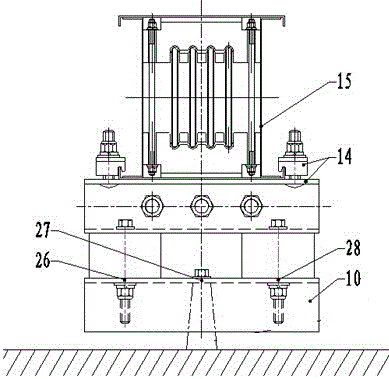

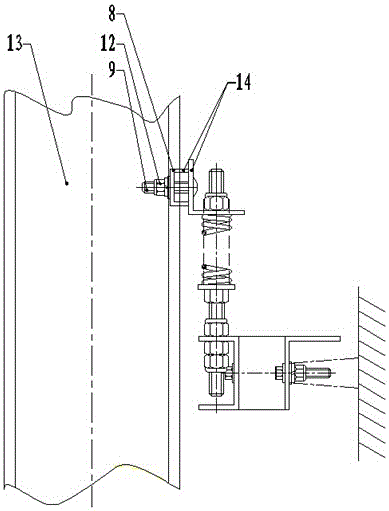

[0017] According to the specifications of the busway, the present invention has three structural forms including two sets of vibration-damping insulating elastic supports, three sets of vibration-damping insulating elastic supports and four sets of vibration-damping insulating elastic supports.

[0018] Now in conjunction with the accompanying drawings, take three groups of vibration-damping insulating elastic supports as an example to describe in detail.

[0019] A special bus duct vibration damping mechanism for wind power, comprising a bus duct 13, a bus duct cover plate 15, at least two sets of double-ended screws 1, in which a spring 3 is arranged; it also includes an L-shaped channel steel connecting seat 2, U-shaped channel steel 6, L-shaped channel steel 10, buffer insulating rubber shock absorber 7, the side of the L-shaped channel steel connecting seat 2 is connected with the bus duct cover plate 15, and the bottom edge of the L-shaped channel steel connecting seat 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com