Motor wiring device

A wiring device and wiring board technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve problems such as difficult wiring and easy cracking of the insulating layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

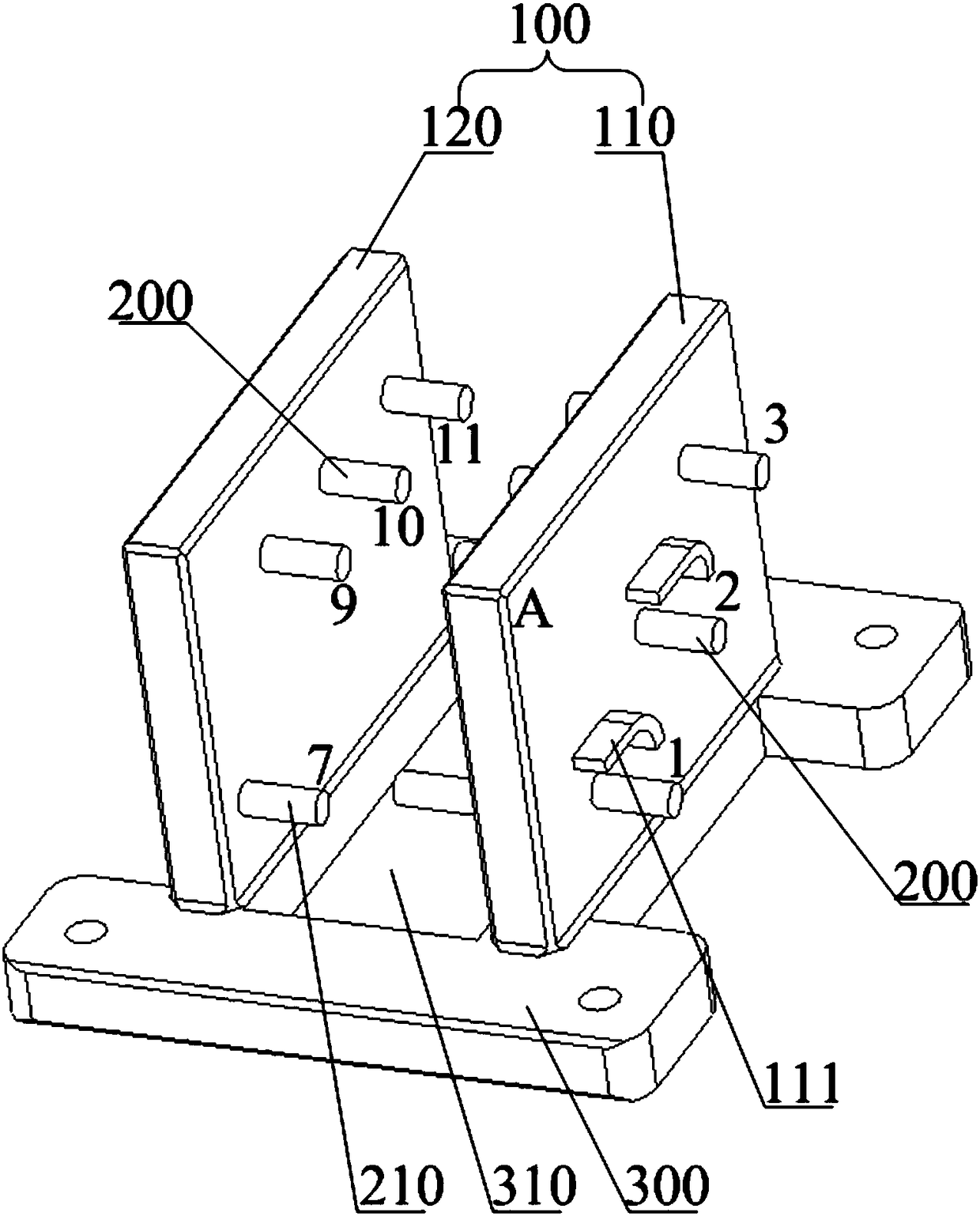

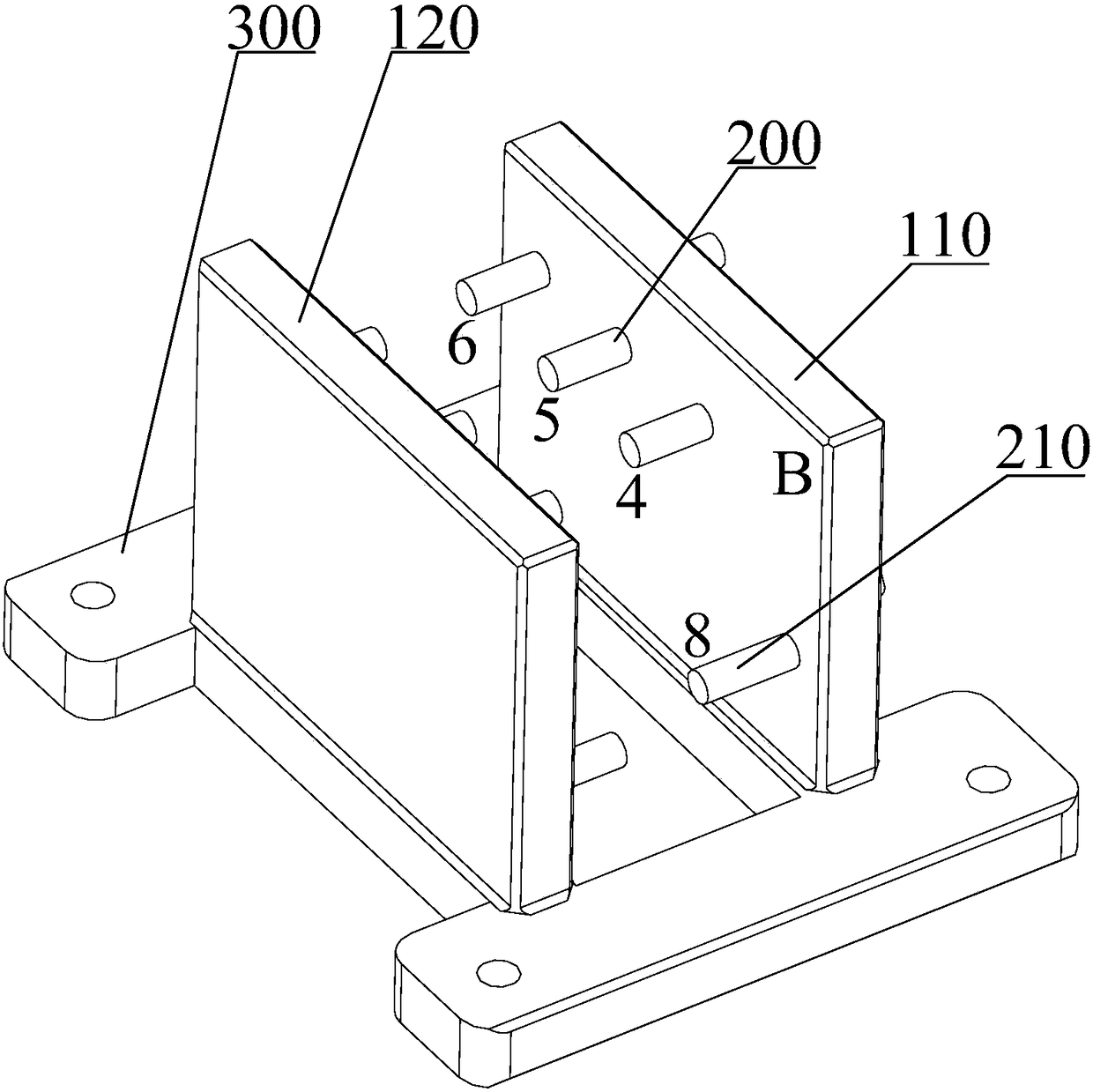

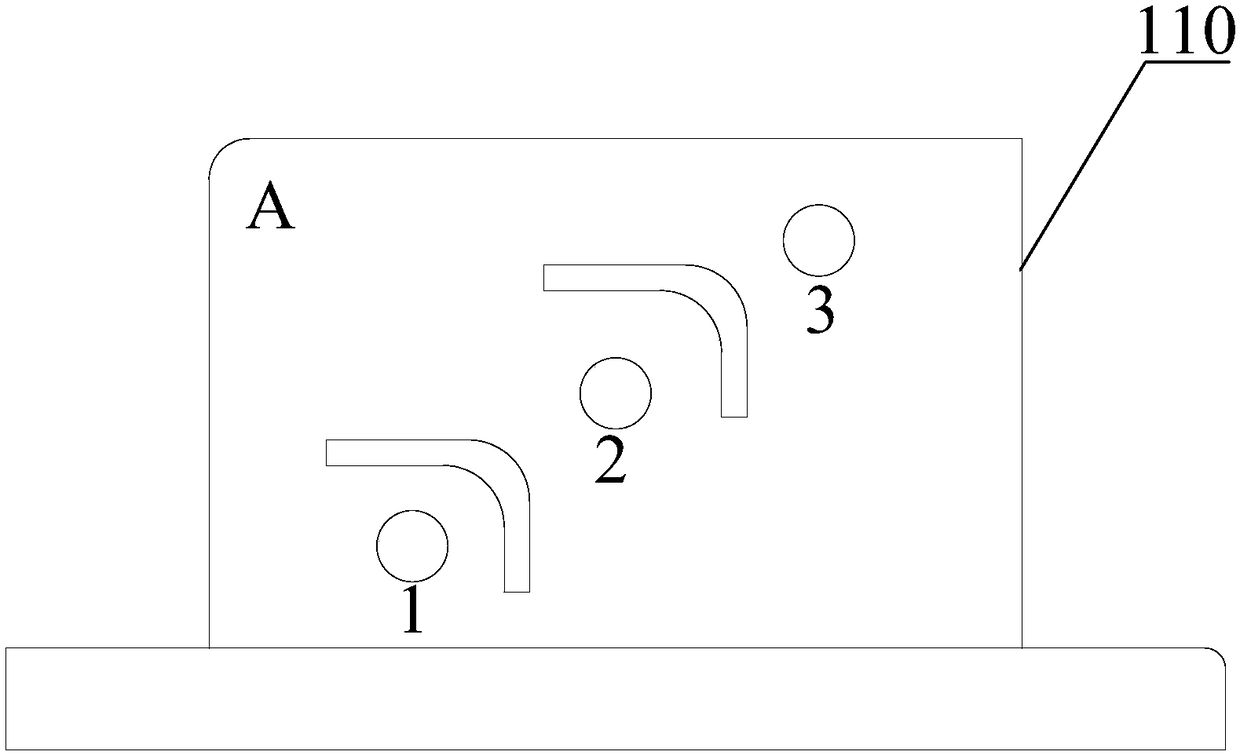

[0036] figure 1 Schematic diagram of the structure of the motor wiring device provided by the embodiment of the present invention Figure 1 ; figure 2 Schematic diagram of the structure of the motor wiring device provided by the embodiment of the present invention Figure II .

[0037] see figure 1 and figure 2 , the present embodiment provides a motor wiring device, including: a terminal board 100 and a terminal 200; The axis is parallel to the bottom surface of the motor outlet box.

[0038] In this way, the terminal 200 is parallel to the bottom surface of the motor outlet box, and the motor lead-out wire can be vertically hung on the terminal 200 without bending, so as to avoid cracking and damage of the insulating layer of the power line.

[0039] As a preferred embodiment, the terminal post 200 is perpendicular to the terminal board 100, and the terminal board 100 is perpendicular to the bottom surface of the motor outlet box. In this way, the terminal post 200 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com