Mainboard, mobile terminal and mainboard manufacturing method

A manufacturing method and motherboard technology, applied in printed circuit manufacturing, electrical components, printed circuits, etc., can solve problems such as damage to electronic component pins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

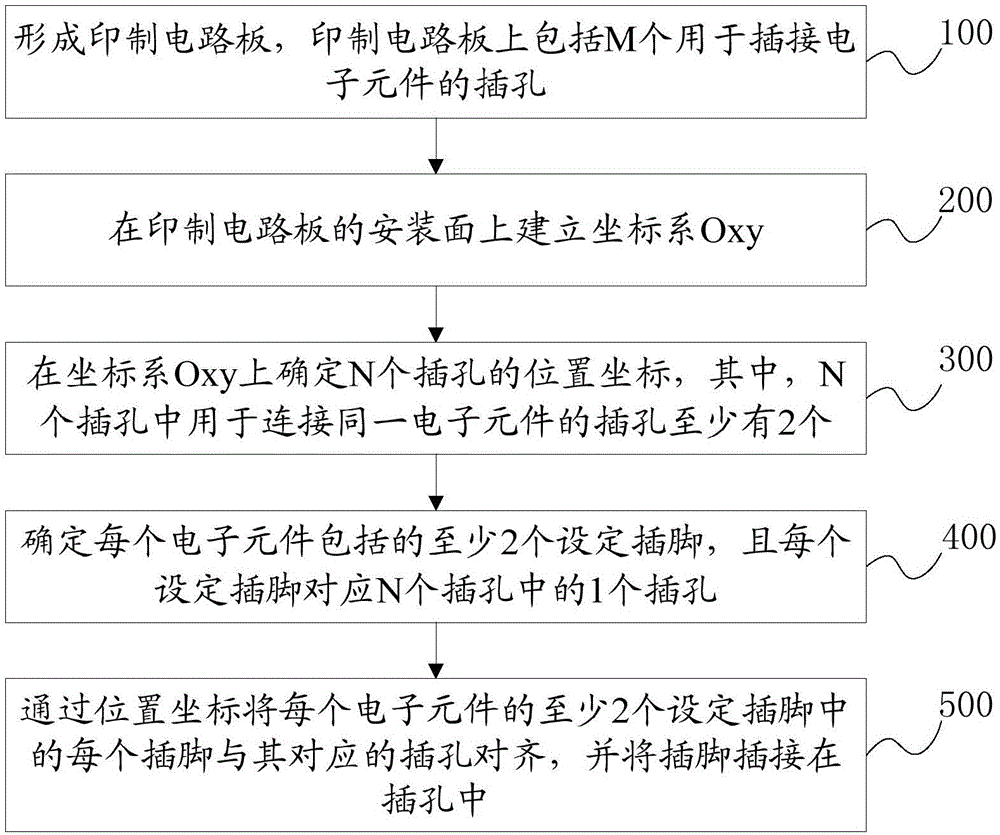

[0034] An embodiment of the present invention provides a method for manufacturing a mainboard, and the execution subject of the method may be an equipment processing center. The following will combine specific implementation methods, figure 1 The processing flow shown is described in detail, and the content can be as follows:

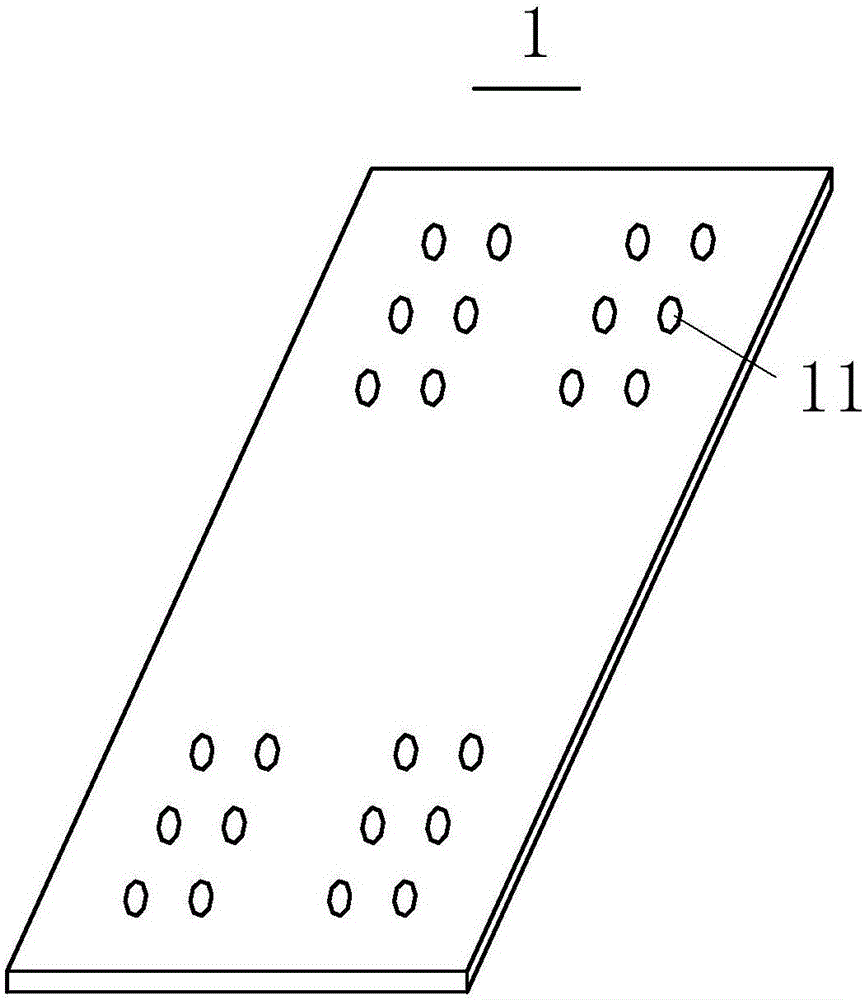

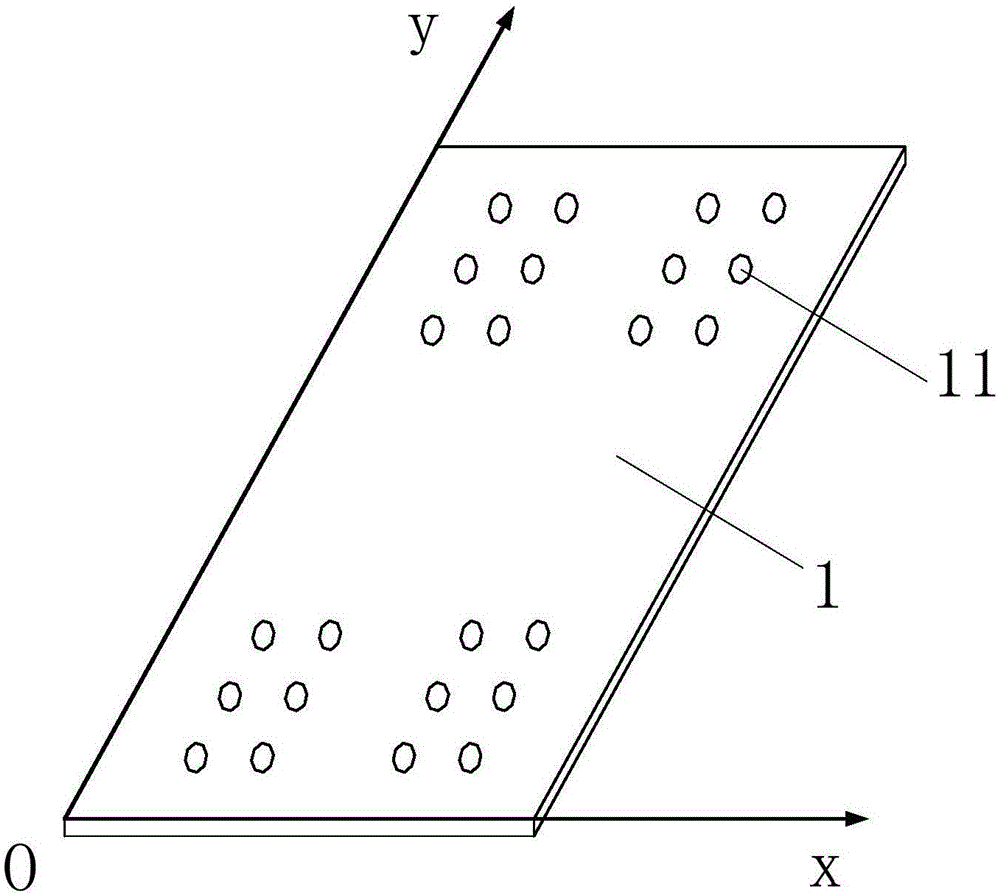

[0035] Step 100, forming a printed circuit board 1, see figure 2 , the printed circuit board 1 includes M jacks 11 for inserting electronic components 2; wherein, M is an integer, and M>2.

[0036] Wherein, the process of forming the printed circuit board 1 is specifically:

[0037] form the substrate;

[0038] forming an insulating layer on the substrate;

[0039] An installation surface is formed on the insulating layer, wherein the installation surface includes a circuit and a plurality of drawing surfaces, and the plurality of drawing surfaces are electrically connected by circuits;

[0040] M sockets 11 for inserting electronic components 2 a...

Embodiment 2

[0057] An embodiment of the present invention provides a main board, and the main board is manufactured according to the manufacturing method for the main board described in the first embodiment.

[0058] The main board provided by the embodiment of the present invention is manufactured by the main board production method described in the first embodiment, so that the production yield of the main board is high, the production cost of the main board is reduced, and the quality of the main board is improved.

Embodiment 3

[0060] An embodiment of the present invention provides a mobile terminal, and the mobile terminal includes the motherboard described in the second embodiment.

[0061] Optionally, the mobile terminal may be a tablet computer or a mobile phone.

[0062] The mobile terminal provided in the embodiment of the present invention adopts the motherboard provided in the second embodiment, so that the production yield of the mobile terminal is high, and the quality of the mobile terminal is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com