An operation and maintenance system for lifting platform vehicles and rail transit rolling stock

A lifting platform vehicle, operation and maintenance technology, applied in the direction of lifting devices, etc., can solve the problems of slow construction progress, heavy electrical boxes, inconvenient handling and installation, etc., to reduce labor intensity, avoid head-up work, and labor-intensive Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

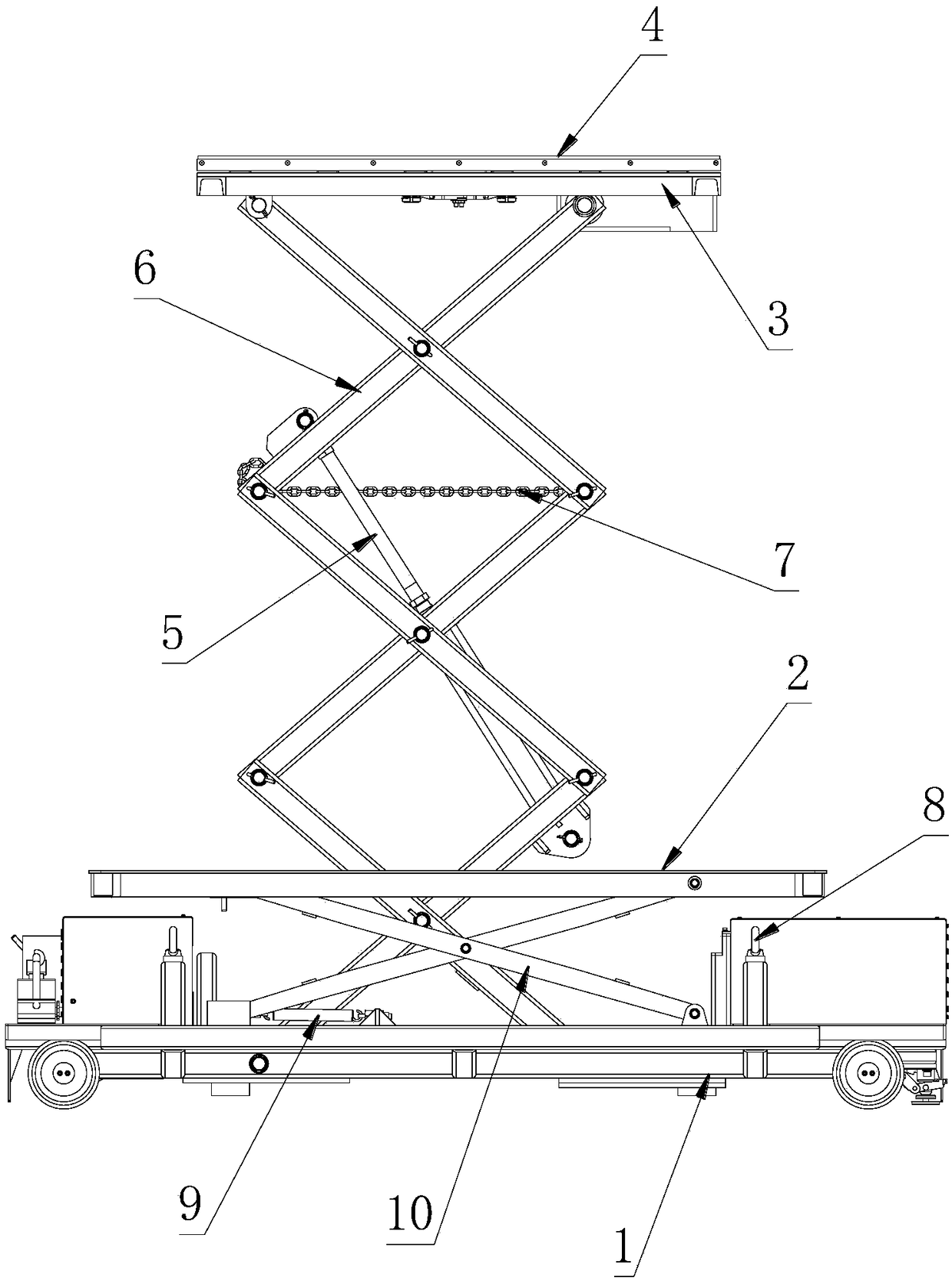

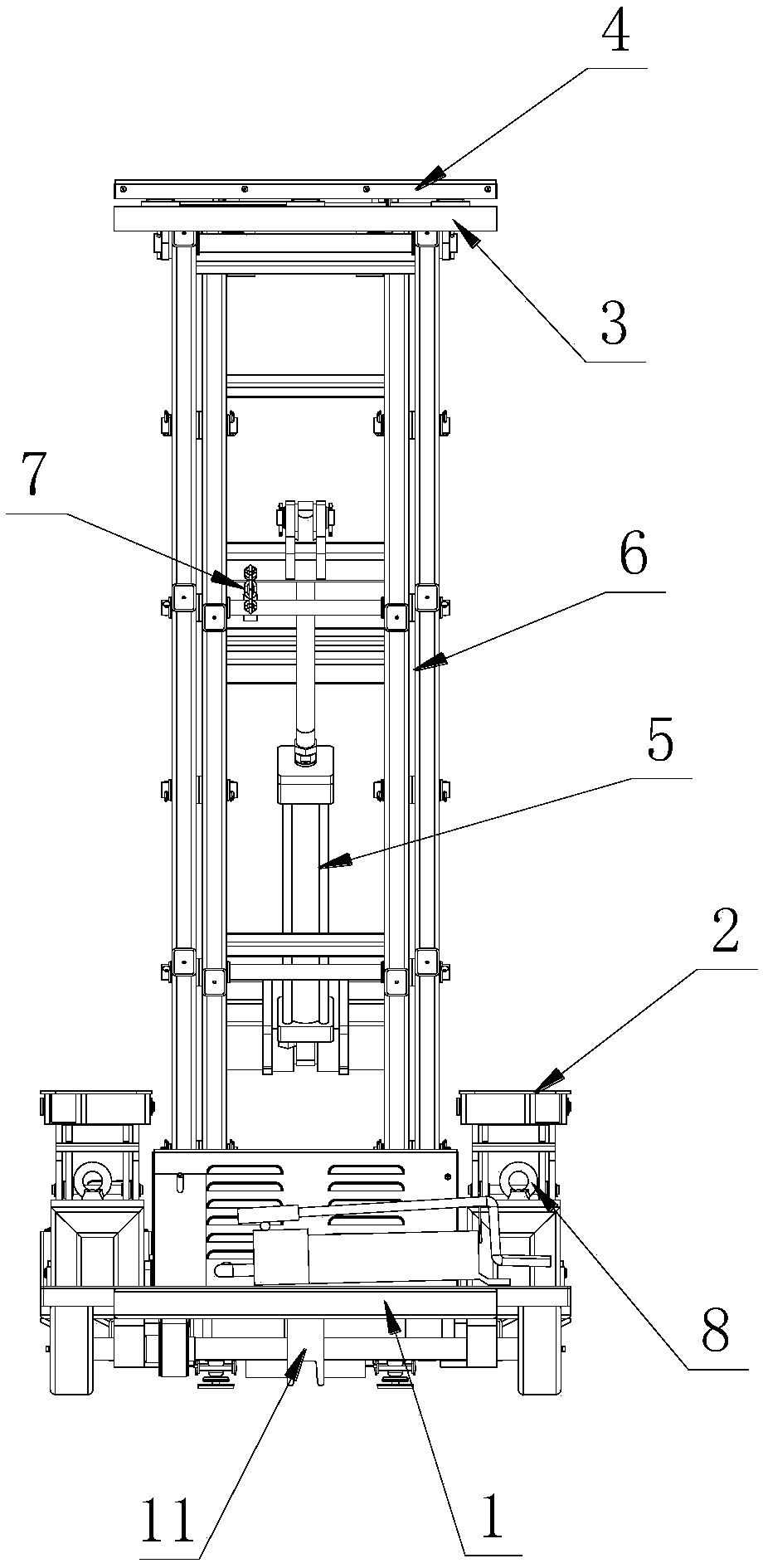

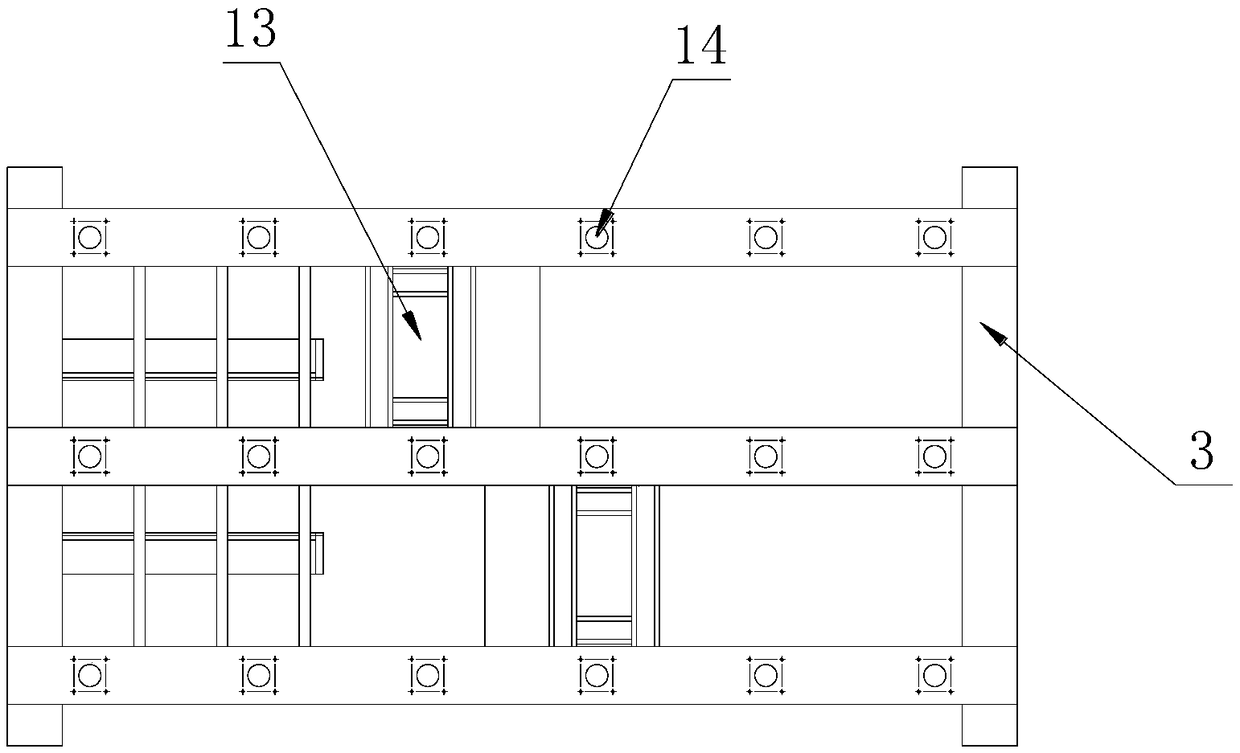

[0057] Such as Figure 1 to Figure 5 As shown, a lifting platform vehicle includes a vehicle body 1. Two multi-layer scissor arm groups 6 are arranged flat on the top of the vehicle body 1 and in the middle position, and the bottom scissor arm in each multi-layer scissor arm group 6 One bottom end of the group is hinged to the car body 1, and the other bottom end is slidably connected to the car body 1. A chute is provided on the car body 1, and the other bottom end of the bottom-layer scissor arm group is slidably clamped in this chute Inside. One top end of the top-level scissor arm group in each multi-layer scissor arm group 6 is hinged with the fixed frame 3, and the other top end is slidably connected with the fixed frame 3; a chute is provided on the fixed frame 3, and the top-level scissor arm The other top of the group is slid and clamped in this chute. In this embodiment, the multilayer scissor arm set 6 is a three-layer scissor arm set.

[0058] Each layer of scissor...

Embodiment 2

[0081] A manned undercarriage inspection vehicle for rail transit locomotives is a lifting platform vehicle described in the first embodiment.

Embodiment 3

[0083] An operation and maintenance system for rail transit locomotives. The operation and maintenance system includes the lifting platform car described in the first embodiment. In particular, it refers to the operation and maintenance system of the maglev train.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com