Motor and EMC element and/or grounding structure of ESD element

一种接地结构、元件的技术,应用在电气元件、电动组件、结构连接等方向,能够解决温度变化无法稳定接地等问题,达到良好接地、稳定接地的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, preferred embodiment of the utility model is described. It should be noted that the following examples are only preferred implementations of the utility model, and the motor structures involved in the utility model are not limited to the motor structures listed in the examples. Features not related to the specific structure of the motor in the specific implementation manner may be equally applicable to any other existing motors, and are not limited by the specific structure of the motor.

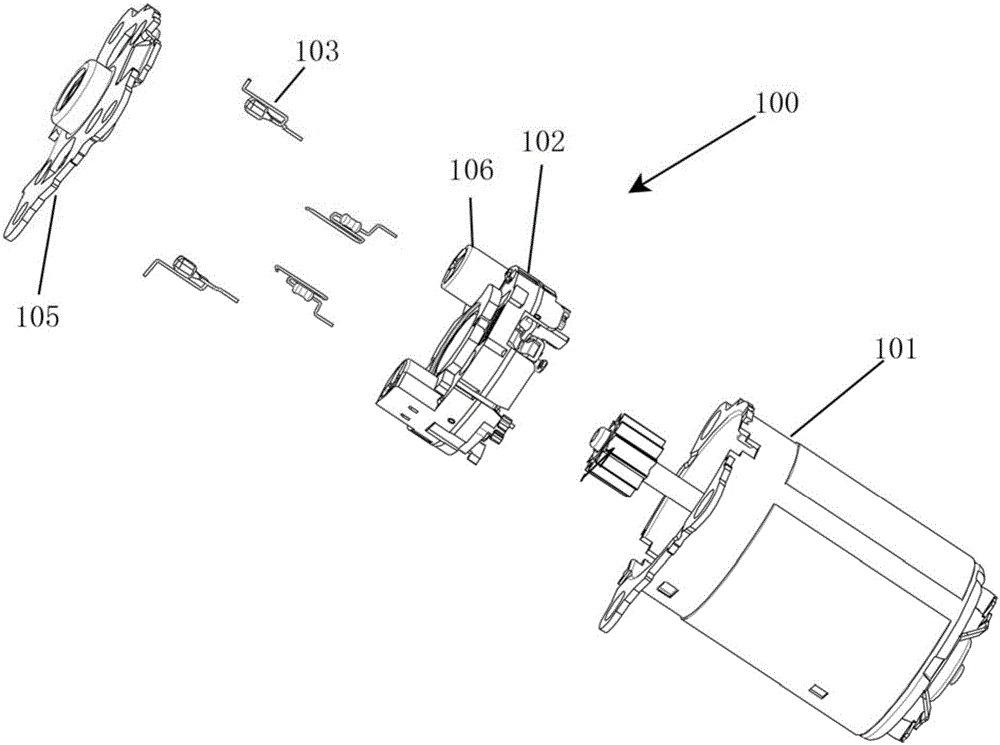

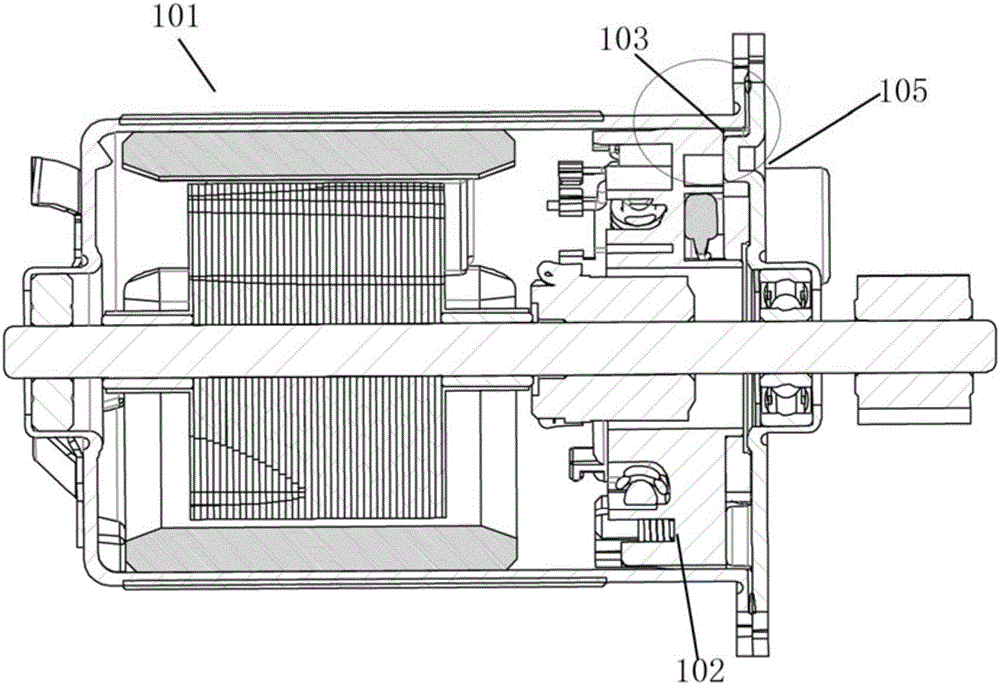

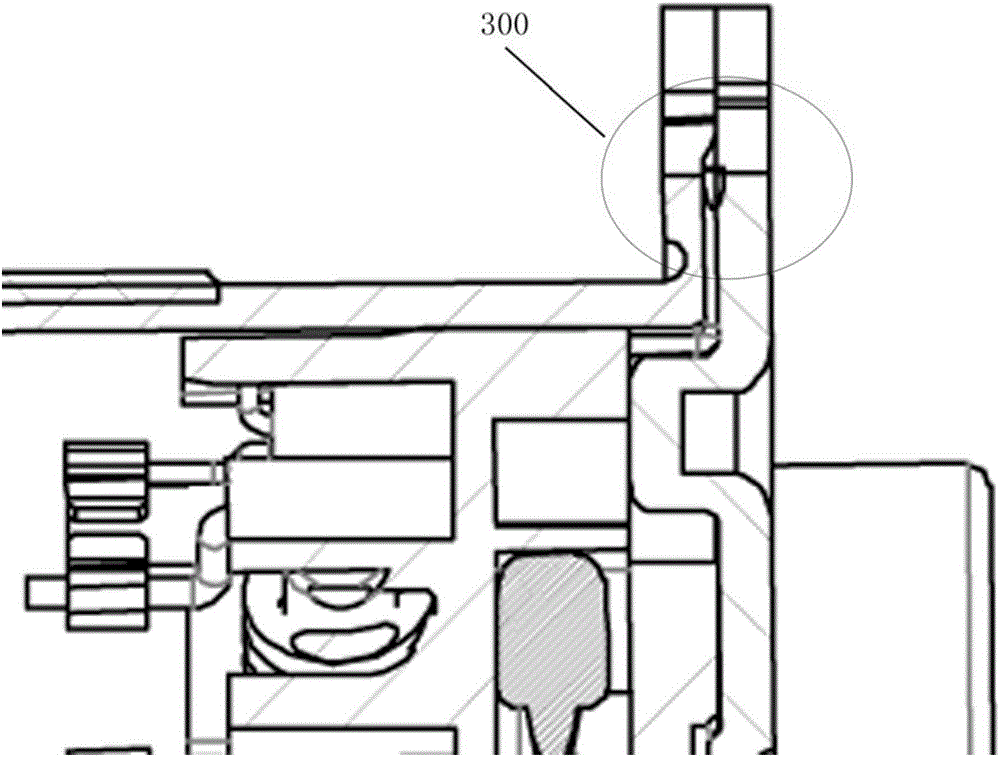

[0035] A preferred embodiment of the utility model provides a motor 100, the internal structure of the motor 100 is as follows figure 1 As shown, the motor 100 includes a conductive housing 101 , a conductive cover 105 , and an insulating cover 102 located inside the conductive cover 105 for accommodating various electronic components and preventing short circuits between the electronic components and the conductive housing 101 and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com