Pressure pot lock cover structure

A pressure cooker and cover locking technology, applied in the field of pressure cooker, can solve the problems that the air flotation valve will be stuck if there is no virtual position, the cover cannot be rotated, and potential safety hazards, etc. It achieves convenient operation, improved safety, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

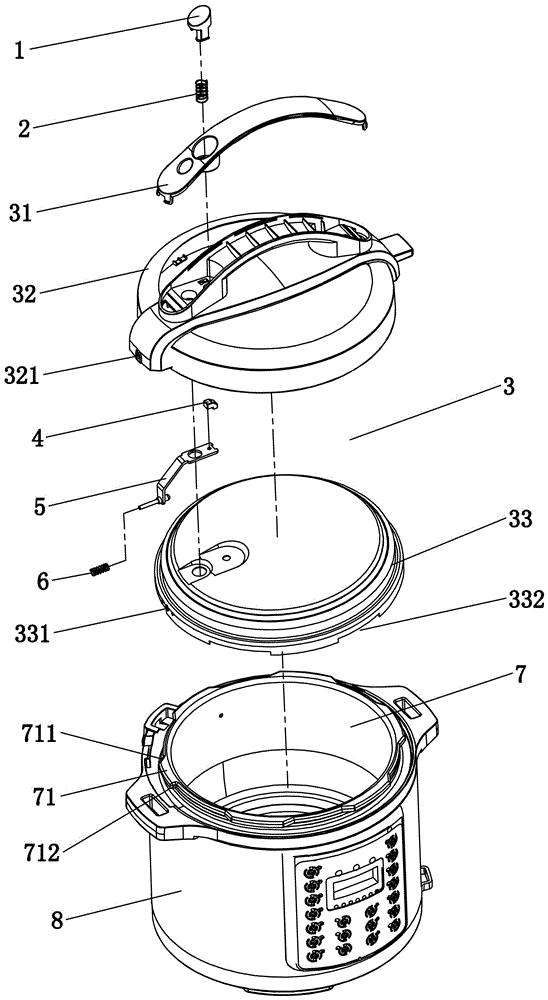

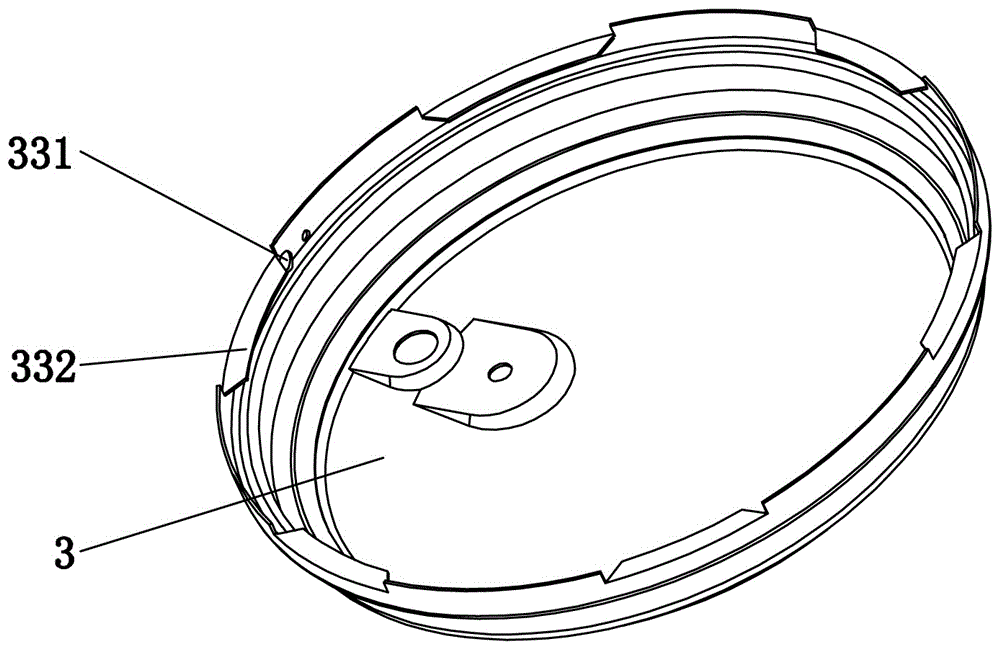

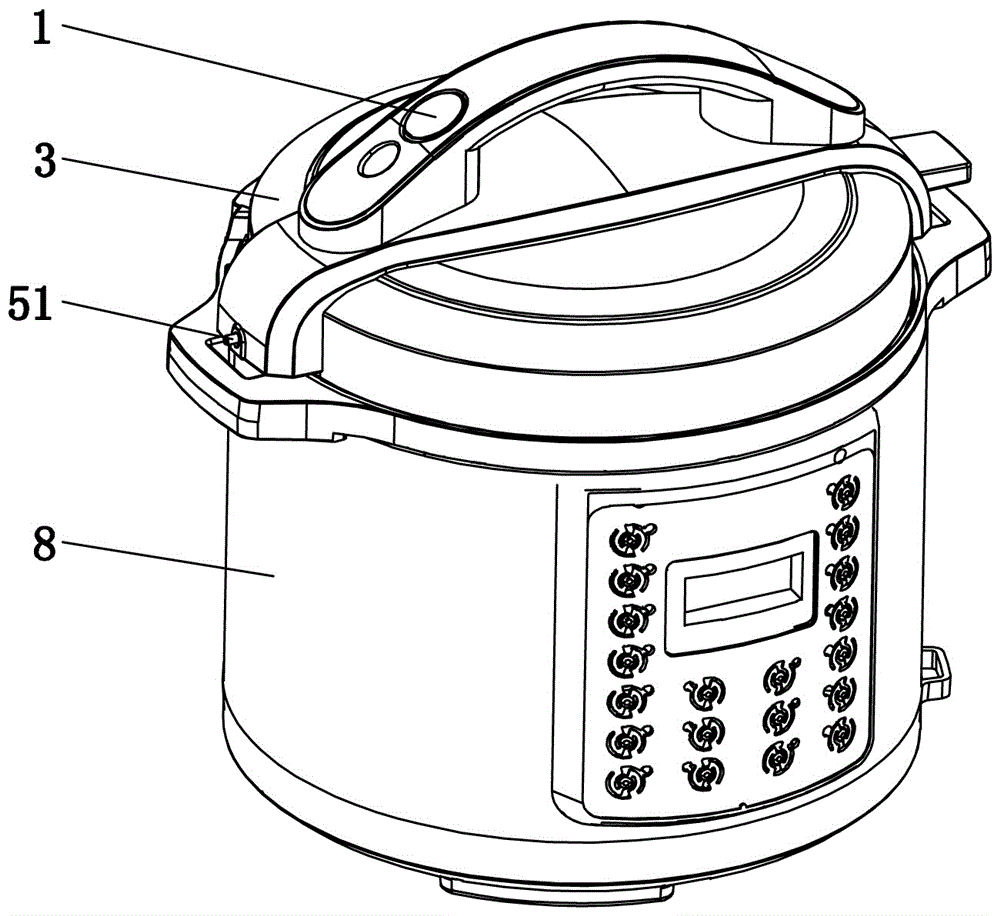

[0030] Embodiment one, see Figure 1 to Figure 6 As shown, a pressure cooker cover structure includes a pot body 8 and a pot cover 3, a plurality of lower pot teeth 71 are annularly arranged on the top of the pot body 8, and upper pot teeth 332 are arranged at the bottom of the pot cover 3, and the upper pot teeth 332 are connected with the lower pot teeth. The number of pot teeth 71 is the same, and the two sides of the lower pot teeth 71 are respectively provided with a forward side 711 and a reverse side, wherein the reverse side of one of the lower pot teeth 71 is a blocking side 712, and the positive side 711 and the rest of the opposite sides are guide hypotenuses; the pot cover 3 is also horizontally slid and provided with a lock pin 52, and the lock pin 52 is located at one end of the upper pot tooth 332 corresponding to the lower pot tooth 71 with the blocking edge 712 above, and the lock pin 52 points to the center of the pot body 8; when the pot cover 3 and the pot ...

Embodiment 2

[0040] Embodiment two, the difference with embodiment one is: see Figure 8 Shown, cancel the relevant parts such as button body 1, and directly set handle 9 on the end that locating pin 51 stretches out pot cover 3, when lock pin and blocking side block, by pulling handle 9 outwards, just can Make the lock pin leave the blocking edge, and now the pot cover can be turned. This structure is only different in the way of controlling the reset of the lock pin from that in Embodiment 1, but the principle is the same, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com