Preparation structure and method for 3D printing welding wire

A 3D printing and welding wire technology, which is applied in the mechanical field, can solve problems such as inconsistent materials, poor equipment adjustability, and easy-to-break welding wire, etc., to achieve the effect of changing the progress and process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiment of the present invention is described below in conjunction with accompanying drawing, embodiment does not constitute limitation of the present invention:

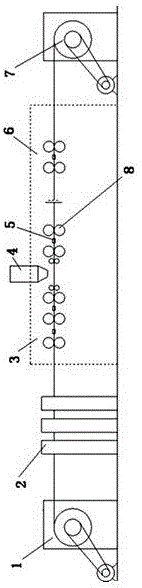

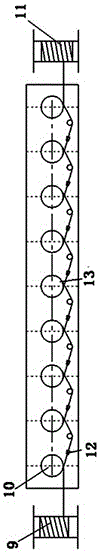

[0026] Option One:

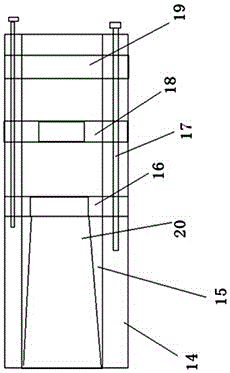

[0027] A 3D printing welding wire preparation structure, including a wire drawing die, characterized in that the middle part of the wire drawing die includes a middle through hole, and the wire drawing die includes a plurality of plate gaps 19, and boards and plates can be placed in the gaps of the plates. The middle part contains the hole. The substantive technical effect and the realization process of the technical solution here are as follows: because there are multiple plate gaps 19, multiple plates can be placed, or a plate can be changed to place the wire drawing die. The overall diameter reduction situation further improves the wire drawing process.

[0028] The wire drawing die includes screw holes, the plate also includes screw holes, and the plate is fixed on the wire drawi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com