Cage-shaped clamping machine

A gripper and cage-like technology is applied in the field of gripping equipment, which can solve the problems of falling objects, inability to use the gripping equipment, insufficient gripping force of the gripping equipment, etc., achieves efficient and stable gripping, and is suitable for popularization and use. , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

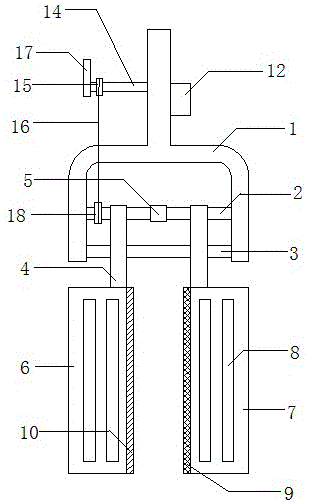

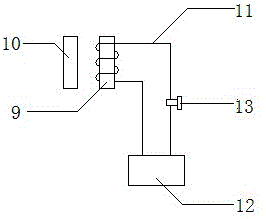

[0017] Such as figure 1 Shown is a schematic view of the structure of the present invention, the present invention is a cage gripper, including a handle bar 1, a screw 2, a slide bar 3, a gripping connecting rod 4, a gripping rod and a locking assembly.

[0018] The hand-held rod 1 is a Y-shaped rod with an opening downward, including a hand-held end and a fixed connection end; Cooperate with screw nut 5, the surface of screw 2 is symmetrically provided with limit grooves on both sides of screw nut 5; the threads on both sides of screw nut 5 are reversely set; the number of clamping connecting rods 4 is two, one end of which is They are all sleeved on the surfac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com