Cylinder ejecting shaft device

A jacking device and cylinder-type technology, which is applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as hidden dangers, loose jacking, and looseness in the winding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

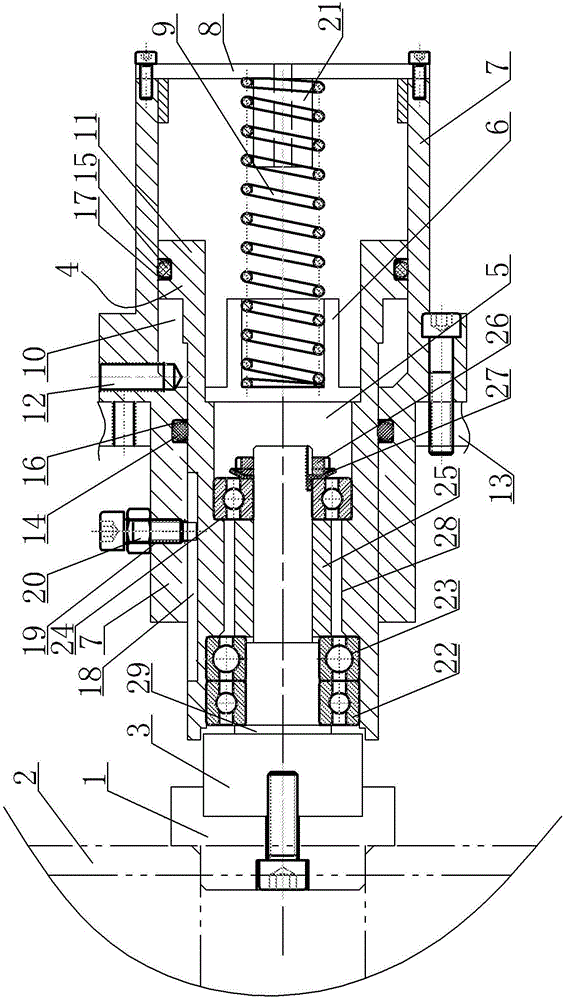

[0013] A cylinder type jacking device, see figure 1 : It includes a top core 1, the top core end surface of the top core 1 is arranged towards the take-up fiber reel 2, one end of the top core 1 away from the top core end surface is fastened to one end of the top core shaft 3, and the other end of the top core shaft 3 passes through The bearing is installed in the front central installation cavity 5 of the movable cylinder 4, the central rear end of the movable cylinder 4 is fixedly equipped with a spring seat 6, and the cylinder seat 7 is set on the outer ring surface of the rear end of the movable cylinder 4, and the rear end of the cylinder seat 7 The cover is equipped with a back cover 8, the back cover 8 is located at the rear of the spring seat 6, the spring seat 6 and the back cover 8 are plugged with a compressed linear spring 9, and the cylinder seat 7 is set on the rear end outer ring surface of the movable cylinder 4 and then they contact each other A closed annular...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com