Yarn guide bar for knitting machine

A yarn guide rod and knitting machine technology, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of affecting knitting precision, easy yarn breakage, yarn jamming, easy falling off, etc., to achieve convenient adjustment, easy replacement, The effect of not easy to break the yarn

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

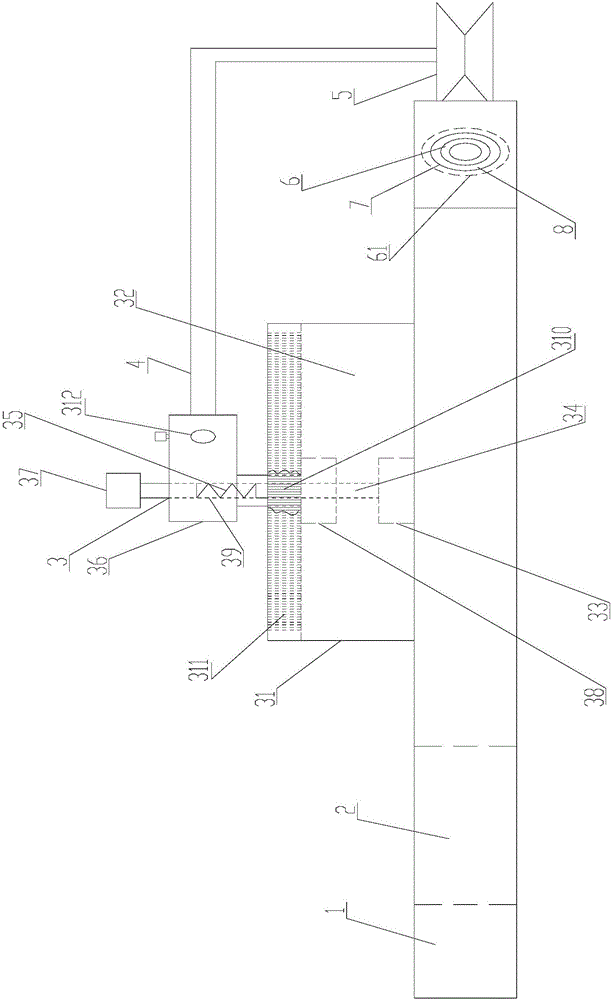

[0016] refer to figure 1 , a yarn guide rod for a knitting machine of the present invention, comprising a body 1, a mounting hole 2, an adjustment seat mechanism 3, a guide wheel rod 4, a guide wheel 5 and a ceramic yarn guide sleeve 6, and the front end of the body 1 is provided with a mounting hole 2. The rear end of the body 1 is provided with a ceramic yarn guide sleeve 6, the body 1 is provided with an adjustment seat mechanism 3, and the adjustment seat mechanism 3 is provided with a guide wheel rod 4, and the guide wheel rod 4 is provided with A guide wheel 5 is provided, and the adjustment seat mechanism 3 includes a track 31, a chute 32, a sliding body 33, an insert body 34, a spring 35, a seat body 36, an adjustment body 37, an anti-falling body 38, and a first through hole 39 , teeth 310 and tooth grooves 311, the body 1 is provided with a track 31, the upper end of the track 31 is provided with a chute 32, the cross section of the chute 32 is a convex shape, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com