Mechanical sealing device for slurry pump

A mechanical seal device and slurry pump technology, which is applied to mechanical equipment, parts of pumping devices for elastic fluids, pumps, etc., can solve the problems of short service life and easy damage, achieve long service life, reduce direct damage, etc. Impact and cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

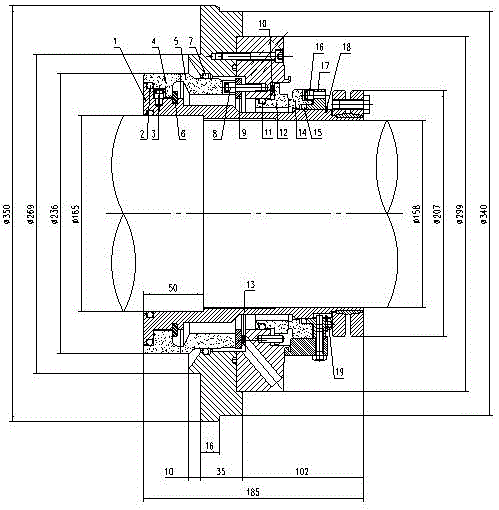

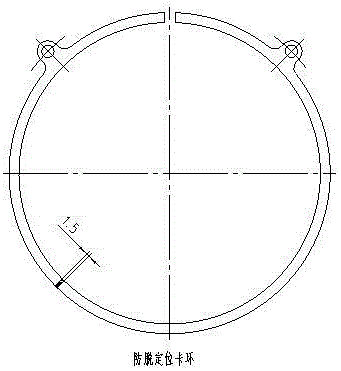

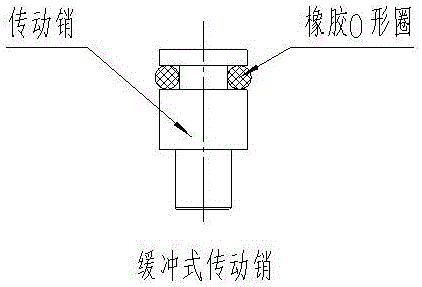

[0012] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. Its structural diagram is as shown in the accompanying drawings. A mechanical seal device for a slurry pump, comprising an inner seal and an outer seal. The inner seal includes an inner moving ring 4, an inner static ring 5, O-rings 2 and 7, a buffer transmission pin 3, a shaft circlip 6, a spring push ring 9 and a spring 13, which are used for sealing liquid and medium of the seal. The outer seal includes an outer moving ring 14, an outer stationary ring 12, O-rings 11 and 15, a buffer transmission pin 16, a push ring 17, a spring 10 and an anti-off positioning snap ring 18 for sealing the sealing liquid. The shaft sleeve 1 is locked on the shaft, the inner moving ring 4 and the outer moving ring 14 rotate simultaneously with the shaft sleeve 1 driven by the shaft, the buffer transmission pin 3 drives t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com